Cart is empty

![]()

- Description

- Robust Frame Construction: Manufactured with advanced technology, featuring precision tolerances and stress relief with welded components.

- Optimized Design: All tensile points designed with large radii to eliminate potential welding cracks.

- Table Inertia: Lower and upper tables designed for optimal inertia, minimizing deformation.

- Vertical Top Plate Positioning: Allows roller bearings, piston bearings, and felts to compensate for vertical loads.

- Double-Sided Hydraulic Cylinders: Honed to 2 microns for minimal wear resistance, made from SAE 1040 forged material.

- Bolted Hydraulic Cylinders: Ensures excellent leveling and load balancing.

- Piston Design: Features omega-type felts with full bronze bearings and semi-angled sleeves for durability.

- Precision Ground Pistons: Hard chrome plated for low friction and abrasion resistance.

- Adjustable Top Tray Slides: Constructed for minimal friction and guided movement in multiple directions.

- Hydraulic System: Ensures precise usage and repeatability at all pressure values up to maximum operating pressure.

- Heavy-Duty Backgauge System: Designed for harsh conditions with scrapping type bearings to prevent dust accumulation.

- Durable Surface Coating: Two layers of paint (60 microns) for weather resistance, dried in advanced ovens.

- Standard Axes: Equipped with Y1, Y2, and X-axes.

- Axes: Y1, Y2, X – 3 Axes

- Control Unit: Esa S625 Touch Screen

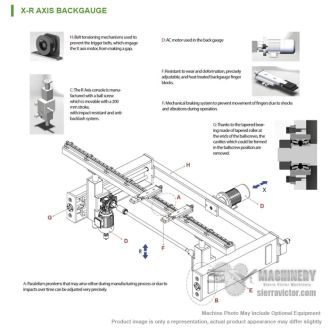

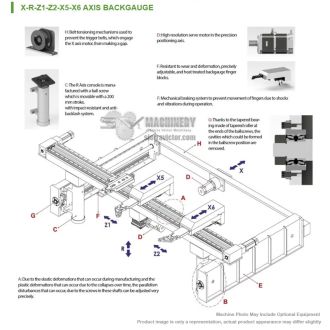

- Back Gauge: X Axis with AC Motor

- Bottom Narrow Table

- Support Arm: Includes scale, T-Slot, and tilting stop.

- Top Tool Clamping: European type.

- Top Tool Specs: H: 66.6mm, 85° R: 08mm

- Bottom Tool Specs: 4V H: 60x60mm, 85°

- Safety Features: Front laser safety manual (Fiessler Akas FPBS) and back safety light curtains.

- Lighting Lamp

- Foot Pedal: With emergency stop button.

- Manufacturer

- Specifications

- Options/Accessories

- Crowning Options: Manual crowning or CNC controller motorized crowning.

- Back Gauge Options: X, R axes with AC motor.

- Foot Pedal: Stand type with emergency stop button.

- Heating Options: Oil heater and oil coolant with fan.

- Tool Clamping: Hydraulic top and bottom tool clamping available.

- Lubrication: Manual or motorized central lubrication systems.

- Safety Certifications: CE certified with manual (Fiessler AKAS II M-FMSC).

- American Tool Holder: Available upon specification of details.

GATOR FAB 88 Ton x 6 ft 4-Axis CNC Hydraulic Press Brake | ADVANCED CAP 2080

STANDARD EQUIPMENT:

ITEM: 6 ft x 88 Ton 4-Axis CNC Hydraulic Press Brake

MANUFACTURER: GATOR FAB

MODEL: ADVANCED CAP 2080

Manufacturer:

Gator Fab

Machine Type

Machine Category:

Press Brakes

Power Source:

Hydraulic

Metalworking

Pressure:

88+ Tons

Material Length:

6 ft (72 in.+)

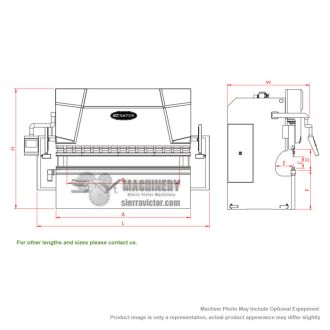

MODEL |

ADVANCED CAP 2080 |

|

Bending Force |

Metric Ton |

80 |

US Ton |

88 |

|

Bending Lenght |

82.7 in. |

|

Stroke |

8.5 in. |

|

Throat Depth |

12.2 in. |

|

Back Gauge X-Axis Stroke |

19.7 in. |

|

Daylight |

17.1 in. |

|

Distance Between Columns |

66.9 in. |

|

R-Axis Speed |

7.9 in/s |

|

Specifications are subject to change without notice.

NOTE: Data is provided by the manufacturer.

WARRANTY: 3 YEAR – Parts

CALL FOR PRICE: