Cart is empty

- Description

-

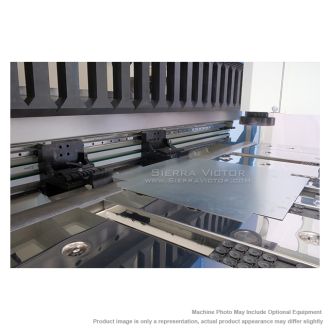

It has a sheet-holding system

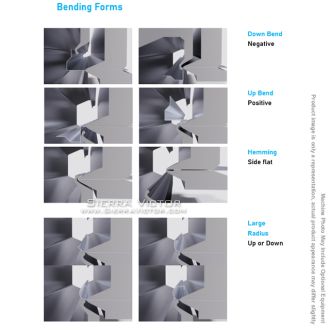

- In ERFOLD CNC control system, each side bend is programmed individually and profile view of the side is shown on the screen after each bend is programmed.

- Each process type on the sides (normal bend,hemming,large radius etc.) is defined,and bending/process length is entered numerically. Application Areas

- Application Areas

- Stainless furniture / trims

- Panels

- Metal architectural accessories and illumination covers

- Electrical cabinets and panels

- Professional kitchen equipments

- Machined and welded steel body frame.

- Manufacturer

- Product Features

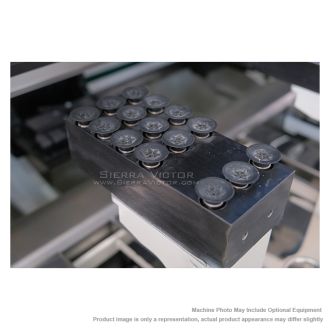

- BLANK HOLDER GROUP:

- Standart 6.69 in. and optional 10 in. high/deep blank holders with movable corner tools.

- Pneumatic tool clamping system to make the tool set-up just in seconds

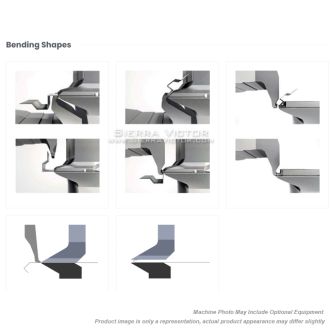

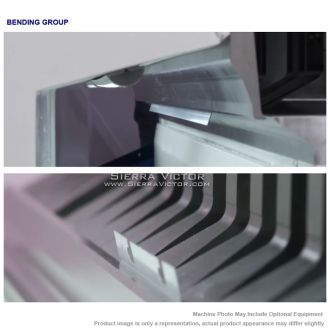

- BENDING GROUP:

- Can execute all the required forms for panels like normal bends up to 140°, side hemming, large radius bending by pressing and also some special functions like air bend by pushing.

- BLANK SHEET SQUARING UNITS:

- Regarding the blank sheet’s long side measure in the programme, they are automatically and motorized positioned in the right and left side on the table, just in front of the bending line. After the pedal command of the cycle start, they go down and dis a appear.

- SHEET SUPPORT TABLE:

- For long life and sensitive materials, all the table is made of inox 304 matte surface stainless steel.

- Upon request, the surface of the table can be equipped with round stainless ball transfers or round brushes

- SERVO MANIPULATOR:

- Thanks to the 3.5 tons of pinching pressure, sheet feeding and rotation is executed with extreme precision in all lengths or thicknesses.

- By the help of repositioning movement, the part can be pinched from the back side of the blank and narrower parts can be processed easily

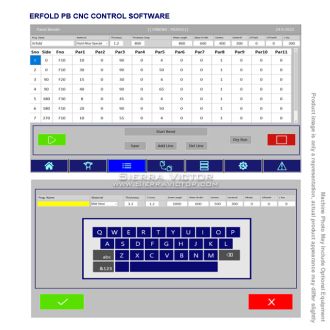

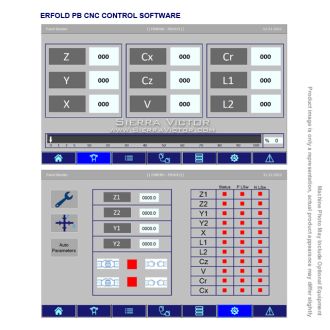

- ERFOLD PB CNC CONTROL SOFTWARE:

- Windows based numerical control software on 15.6" touchscreen controller

- In ERFOLD PB controller software, each bending step of each side is programmed numerically and functionally.

- First bend type is defined (normal bend,hemming,auto radius etc),and flange length is entered

- After bending measures, you enter sheet manipulation commands/functions like rotate +/- 90°/180°

- Although numerical programming looks difficult, by means of making precise adjustment regarding the material’s reaction, it is much more advantageous.

- Specifications

ERBEND CNC Compact Panel Bender | PBC

ITEM: CNC Compact Panel Bender

MANUFACTURER: ERBEND

MODEL: PBC

Manufacturer:

Erbend

Machine Type

Machine Category:

Panel Benders

Control:

CNC

Material Type:

Metal

Metalworking

Material Length:

5 ft (60 in.+)

Mild Steel Capacity:

16 ga

|

PARAMETERS

|

MODEL

|

||

|

PBC 1515/1520

|

PBC 2015/2020

|

PBC 2515/2520

|

|

|

MAX PANEL LENGTH

|

61 in.

|

80.7 in.

|

100.39 in.

|

|

MAX PANEL WIDTH

|

49.21 in.

|

49.21 in.

|

49.21 in.

|

|

MIN PANEL DIMENSIONS

|

5.9 in. width x 9.05 in. length

|

||

|

MAX PANEL DEPTH/HEIGHT

(STD/OPT) |

6.69 / 10 in.

|

||

|

MAX SHEET THICKNES

(Steel/Galvanized-400 N/mm2) |

0.059 / 0.078 in.

|

||

|

MAX SHEET THICKNESS

(Stainless – 600 N/mm2) |

0.039 / 0.059 in.

|

||

|

MAX SHEET THICKNESS

(Aluminum – 270 N/mm2) |

0.078 / 0.118 in.

|

||

|

MIN SHEET THICKNESS

|

0.015 in.

|

||

|

MIN FLANGE/BEND LENGTH

|

Thickness x 10

|

||

|

TIME PER BEND

|

0.3 sn

|

||

|

MANIPULATOR ARM

FEEDING SPEED |

1.000 mm/sec

|

||

|

MANIPULATOR ARM

ROTATION SPEED |

180°/sec

|

||

|

NUMBER OF CNC AXIS

|

14

|

||

|

MAX POWER - CONSUMPTION

|

40 kw installed - 3 kw/h consumption

|

||

|

ELECTRICITY REQUIREMENT

|

380v/40a/50hz

|

||

|

MACHINE LAYOUT

DIMENSIONS (INCH) |

216.5 x 94.5 x 94.5

|

216.5 x 114 x 94.5

|

216.5 x 133.8 x 94.5

|

|

MACHINE TOTAL

GROSS WEIGHT |

16,535 lbs.

|

20,944 lbs.

|

25,353 lbs.

|

|

MODEL

|

Max Sheet Length

|

Steel/Galv

(400 N/MM2) |

Stainless

(600 N/MM2) |

Aluminum

(270 N/MM2) |

|

PBC 1515

|

61 in.

(5 ft) |

0.059 in.

(1,5mm) |

0.039 in.

(1mm) |

0.078 in.

(2 mm) |

|

PBC 1520

|

61 in.

(5 ft) |

0.078 in.

(2 mm) |

0.059 in.

(1.5 mm) |

0.011

(3 mm) |

|

PBC 2015

|

80.7 in.

(6.7 ft) |

0.059 in.

(1,5mm) |

0.039 in.

(1mm) |

0.078 in.

(2 mm) |

|

PBC 2020

|

80.7 in.

(6.7 ft) |

0.078 in.

(2 mm) |

0.059 in.

(1.5 mm) |

0.011

(3 mm) |

|

PBC 2515

|

100.39 in.

(8.3 ft) |

0.059 in.

(1,5mm) |

0.039 in.

(1mm) |

0.078 in.

(2 mm) |

|

PBC 2520

|

100.39 in.

(8.3 ft) |

0.078 in.

(2 mm) |

0.059 in.

(1.5 mm) |

0.011

(3 mm) |

Specifications are subject to change without notice.

NOTE: Data is provided by the manufacturer.

WARRANTY: 1 YEAR – Parts