<p><b>SPECIFICATIONS</b></p>

<table cellspacing="0" cellpadding="0" border="1" width="520">

<tbody style="text-align: center;">

<tr bgcolor="#333333" class="Title_white1">

<td class="Title_white_bold"><div align="center" class="Title_white_bold1">

<div align="center"><b><span style="color: rgb(255, 255, 255);">MODEL </span></b></div>

</div></td>

<td width="212" bgcolor="#333333" class="TableText1"><div align="center"></div></td>

<td width="204" class="TableText1"><div align="center" class="Title_white_bold">

<div align="center"><b><span style="color: rgb(255, 255, 255);">40120M </span></b></div>

</div></td>

</tr>

<tr>

<td width="96" rowspan="4" bgcolor="#333333" class="Title_white_bold"><div align="center"><strong><span style="color: rgb(255, 255, 255);">CAPACITY</span></strong></div></td>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Swing over bed</div></td>

<td class="TableText1"><div align="center">40 in. (1,016 mm)</div></td>

</tr>

<tr>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Swing over cross slide</div></td>

<td class="TableText1"><div align="center">24.02 in. (610 mm)</div></td>

</tr>

<tr>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Swing over gap</div></td>

<td class="TableText1"><div align="center">51.19 in. <br>

(1300.2 mm)</div></td>

</tr>

<tr>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Distance between centers</div></td>

<td class="TableText1"><div align="center">120 in. <br>

(3,048 mm)</div></td>

</tr>

<tr>

<td rowspan="4" bgcolor="#333333" class="Title_white_bold"><div align="center"><span style="color: rgb(255, 255, 255);"><strong> </strong><strong>HEADSTOCK</strong></span></div></td>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Spindle Speed</div></td>

<td class="TableText1"><div align="center">4-420 rpm</div></td>

</tr>

<tr>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">No. of Spindle Speeds</div></td>

<td class="TableText1"><div align="center">16 steps</div></td>

</tr>

<tr>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Spindle nose</div></td>

<td valign="top" class="TableText1"><div align="center">A2-11</div></td>

</tr>

<tr>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Spindle bore</div></td>

<td class="TableText1"><div align="center">6 in. (152.4 mm)</div></td>

</tr>

<tr>

<td rowspan="7" bgcolor="#333333" class="Title_white_bold"><div align="center"><span style="color: rgb(255, 255, 255);"><strong> </strong><strong>THREADS AND FEEDS</strong></span></div></td>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Inch Threads, Number</div></td>

<td class="TableText1"><div align="center">0.25-30 tpi, 70</div></td>

</tr>

<tr>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Metric Threads, Number</div></td>

<td class="TableText1"><div align="center">1-120 mm, 62</div></td>

</tr>

<tr>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Modular Threads, Number</div></td>

<td class="TableText1"><div align="center">0.25-30 M.P., 53</div></td>

</tr>

<tr>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Diametral Pitch Threads, Number</div></td>

<td class="TableText1"><div align="center">1-120 D.P., 70</div></td>

</tr>

<tr>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Longitudinal Feeds</div></td>

<td class="TableText1"><div align="center">0.0024-0.28 in/rev <br>

(0.0609-7.11 mm/rev)</div></td>

</tr>

<tr>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Cross Feeds</div></td>

<td class="TableText1"><div align="center">0.0012-0.14 in/rev <br>

(0.0304-3.55 mm/rev)</div></td>

</tr>

<tr>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Leadscrew Pitch, Diameter</div></td>

<td class="TableText1"><div align="center">2 tpi, 2.36 in.</div></td>

</tr>

<tr>

<td rowspan="3" bgcolor="#333333" class="Title_white_bold"><div align="center"><strong> </strong><strong><span style="color: rgb(255, 255, 255);">CARRIAGE</span></strong></div></td>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Cross slide travel</div></td>

<td class="TableText1"><div align="center">27.6 in. (701.04 mm)</div></td>

</tr>

<tr>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Compound Travel</div></td>

<td class="TableText1"><div align="center">15.75 in. (400.05 mm)</div></td>

</tr>

<tr>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Compound Width</div></td>

<td class="TableText1"><div align="center">34.65 in. (880.11 mm)</div></td>

</tr>

<tr>

<td rowspan="2" bgcolor="#333333" class="Title_white_bold"><div align="center"><strong> </strong><strong><span style="color: rgb(255, 255, 255);">BED</span></strong></div></td>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Bed Length</div></td>

<td class="TableText1"><div align="center">212 in. <br>

(5384.8 mm)</div></td>

</tr>

<tr>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Bed width</div></td>

<td class="TableText1"><div align="center">32 in. (812.8 mm)</div></td>

</tr>

<tr>

<td rowspan="3" bgcolor="#333333" class="Title_white_bold"><div align="center"><strong> </strong><strong><span style="color: rgb(255, 255, 255);">TAILSTOCK</span></strong></div></td>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Quill Diameter</div></td>

<td class="TableText1"><div align="center">4.53 in. (115.06 mm)</div></td>

</tr>

<tr>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Quill Travel</div></td>

<td class="TableText1"><div align="center">12 in. (304.8 mm)</div></td>

</tr>

<tr>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Quill Center Taper</div></td>

<td class="TableText1"><div align="center">MT #6</div></td>

</tr>

<tr>

<td rowspan="5" bgcolor="#333333" class="Title_white_bold"><div align="center"><strong><span style="color: rgb(255, 255, 255);">GENERAL</span></strong></div></td>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Spindle Motor</div></td>

<td class="TableText1"><div align="center">30 HP (22.37 Kw)</div></td>

</tr>

<tr>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Voltage</div></td>

<td class="TableText1"><div align="center">220V/440V</div></td>

</tr>

<tr>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Phase</div></td>

<td class="TableText1"><div align="center">3-Phase</div></td>

</tr>

<tr>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Approximate Weight</div></td>

<td class="TableText1"><div align="center">23,980 lbs. <br>

(10,877 Kg)</div></td>

</tr>

<tr>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Dimensions</div></td>

<td class="TableText1"><div align="center">18.73x7.11x5.05ft <br>

(5.70x2.16x1.53M)</div></td>

</tr>

</tbody>

</table>

<p><b><br></b></p>

<p><b>FEATURES</b></p>

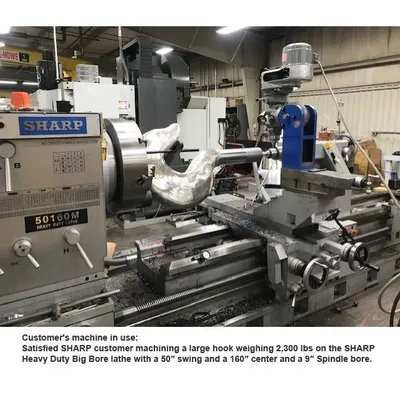

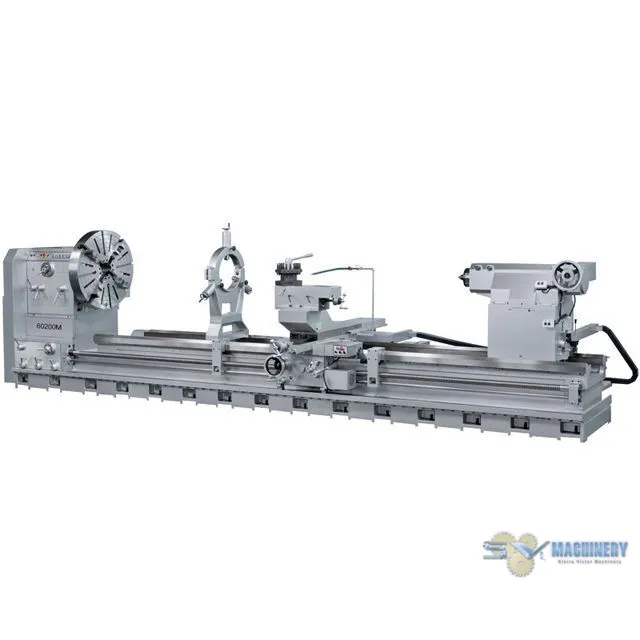

<ul><li>The big bore lathe is ideal for large pipe works in oil fields and big valves works. This series offers spindle bores up to 15", center distance range from 60" to 315". The machine bed is 32" wide. Double chucks are available for holding extra long and large work pieces.</li><li>Swing over bedways: 40", 50", 60", 70", 80"</li><li>Bet centers: 60" – 315"</li><li>Spindle bore: 6" standard, 9", 12", 15", optional</li><li>Spindle motor: 30 HP, larger HP available</li><li>Bed width: 32"</li><li>Massive one- piece casting machine base</li><li><strong>Three points support headstock spindle:</strong><ul><li>The headstock casting is designed with one ball bearing and two tapered roller bearings supporting the full length of the spindle shaft.</li><li>Spindle bore sizes are available in 6”, 9” and 12” , 15”</li><li>Gears and shafts are made from hardened and ground alloy steel, the spindle is made from forged, chrome alloy material.</li></ul></li><li><strong>Solid one piece casting base:</strong><ul><li>The one piece casting bed is fully ribbed to prevent distortion under heavy cutting conditions. The base casting of the headstock is ribbed to withstand stress and distortion due to heavy machining conditions</li><li>The oversized 24” wide bedways are induction hardened and ground for long lasting accuracy.</li><li>An additional third bed way is provided on the front of the bed, giving extra support to the carriage during heavy cutting conditions</li></ul></li><li><strong>Double Chuck, Gear Box:</strong><ul><li>The headstock can accommodate double chucks when necessary.</li><li>The fully enclosed quick change gear box allows easy change of wide range of inch, metric, MP and DP threads without exchanging gears.</li></ul></li><li><strong>Power Tailstock:</strong><ul><li>Tailstock is equipped with a 2 step quill feed for ease of infeed. Large hand crank allows convenient positioning of tailstock.</li><li>For larger models, motorized quill feed and power drive tailstock units are available as options. (picture shows optional power driven tailstock unit)</li></ul></li></ul>

<p><strong> STANDARD ACCESSORIES:</strong></p>

<ul><li>16 Spindle speed</li><li>2 stage spindle start up</li><li>Headstock oil bath system</li><li>Electro magnetic brake</li><li>Lubrication system</li><li>Coolant system</li><li>Manual tailstock</li><li>Steady rest 16”</li><li>Work lamp</li></ul>