<p><b>SPECIFICATIONS</b></p>

<table cellspacing="0" cellpadding="0" border="1" width="520">

<tbody style="text-align: center;">

<tr bgcolor="#333333" class="Title_white1">

<td class="Title_white_bold"><div align="center" class="Title_white_bold1">

<div align="center"><b><span style="color: rgb(255, 255, 255);">MODEL</span></b></div>

</div></td>

<td bgcolor="#333333" class="TableText1"><div align="center"></div></td>

<td width="131" class="TableText1"><div align="center" class="Title_white_bold">

<div align="center"><b><span style="color: rgb(255, 255, 255);">22120B</span></b></div>

</div></td>

</tr>

<tr>

<td width="86" rowspan="4" bgcolor="#333333" class="Title_white_bold"><div align="center"><strong><span style="color: rgb(255, 255, 255);">CAPACITY</span></strong></div></td>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Swing over bed</div></td>

<td class="TableText1"><div align="center">22 in. (558.8 mm)</div></td>

</tr>

<tr>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Swing over cross slide</div></td>

<td class="TableText1"><div align="center">13.2 in. (335.28 mm)</div></td>

</tr>

<tr>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Swing over gap</div></td>

<td class="TableText1"><div align="center">31 in. (787.4 mm)</div></td>

</tr>

<tr>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Distance between centers</div></td>

<td class="TableText1"><div align="center">120 in. <br>

(3,048 mm)</div></td>

</tr>

<tr>

<td rowspan="4" bgcolor="#333333" class="Title_white_bold"><div align="center"><strong> </strong><strong><span style="color: rgb(255, 255, 255);">HEADSTOCK</span></strong></div></td>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Spindle Speed</div></td>

<td valign="top" class="TableText1"><div align="center">10-1,000 rpm</div></td>

</tr>

<tr>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">No. of Spindle Speeds</div></td>

<td class="TableText1"><div align="center">12</div></td>

</tr>

<tr>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Spindle nose</div></td>

<td valign="top" class="TableText1"><div align="center">D1-11 camlock</div></td>

</tr>

<tr>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Spindle bore</div></td>

<td class="TableText1"><div align="center">4.5 in. (114.3 mm)</div></td>

</tr>

<tr>

<td rowspan="7" bgcolor="#333333" class="Title_white_bold"><div align="center"><span style="color: rgb(255, 255, 255);"><strong> </strong><strong>THREADS AND FEEDS</strong></span></div></td>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Inch Threads, Number</div></td>

<td class="TableText1"><div align="center">2-56 tpi, 44</div></td>

</tr>

<tr>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Metric Threads, Number</div></td>

<td class="TableText1"><div align="center">0.5-14 mm, 24</div></td>

</tr>

<tr>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Modular Threads, Number</div></td>

<td class="TableText1"><div align="center">0.019-0.55 in., 24 (0.5-14 mm, 24)</div></td>

</tr>

<tr>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Diametral Pitch Threads, Number</div></td>

<td class="TableText1"><div align="center">0.157-2.20 in., 36 (4-56 mm, 36)</div></td>

</tr>

<tr>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Longitudinal Feeds</div></td>

<td class="TableText1"><div align="center">0.0022-0.032 in., 18 <br>

(0.055-0.812 mm, 18)</div></td>

</tr>

<tr>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Cross Feeds</div></td>

<td class="TableText1"><div align="center">0.00026-0.035 in., 17 <br>

(0.0066-0.889 mm, 17)</div></td>

</tr>

<tr>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Leadscrew Pitch, Diameter</div></td>

<td class="TableText1"><div align="center">4 tpi, 1.5 in.</div></td>

</tr>

<tr>

<td rowspan="3" bgcolor="#333333" class="Title_white_bold"><div align="center"><strong> </strong><strong><span style="color: rgb(255, 255, 255);">CARRIAGE</span></strong></div></td>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Cros slide travel</div></td>

<td class="TableText1"><div align="center">11.8 in. (299.72 mm)</div></td>

</tr>

<tr>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Compound Travel</div></td>

<td class="TableText1"><div align="center">6.2 in. <br>

(157.48 mm)</div></td>

</tr>

<tr>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Compound Width</div></td>

<td class="TableText1"><div align="center">6 in. (152.4 mm)</div></td>

</tr>

<tr>

<td rowspan="2" bgcolor="#333333" class="Title_white_bold"><div align="center"><span style="color: rgb(255, 255, 255);"><strong> </strong><strong>BED</strong></span></div></td>

<td width="162" bgcolor="#CCCCCC" class="TableText1"><div align="center">Bed length</div></td>

<td class="TableText1"><div align="center">153 in. <br>

(3,886.2 mm)</div></td>

</tr>

<tr>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Bed width</div></td>

<td class="TableText1"><div align="center">15.75 in. (400.05 mm)</div></td>

</tr>

<tr>

<td rowspan="3" bgcolor="#333333" class="Title_white_bold"><div align="center"><strong> </strong><strong><span style="color: rgb(255, 255, 255);">TAILSTOCK</span></strong></div></td>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Quill Diameter</div></td>

<td class="TableText1"><div align="center">3 in. (76.2 mm)</div></td>

</tr>

<tr>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Quill Travel</div></td>

<td class="TableText1"><div align="center">6.5 in. (165.1 mm)</div></td>

</tr>

<tr>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Quill Center Taper</div></td>

<td class="TableText1"><div align="center">MT #5</div></td>

</tr>

<tr>

<td rowspan="7" bgcolor="#333333" class="Title_white_bold"><div align="center"><strong><span style="color: rgb(255, 255, 255);">GENERAL</span></strong></div></td>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Spindle Motor</div></td>

<td class="TableText1"><div align="center">15 HP (11.18 Kw)</div></td>

</tr>

<tr>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Voltage</div></td>

<td class="TableText1"><div align="center">220V/440V</div></td>

</tr>

<tr>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Phase</div></td>

<td class="TableText1"><div align="center">3 phase</div></td>

</tr>

<tr>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Power Consumption (220V)</div></td>

<td class="TableText1"><div align="center">16KVA/45 amps</div></td>

</tr>

<tr>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Power Consumption (440V)</div></td>

<td class="TableText1"><div align="center">16KVA/22.5 amps</div></td>

</tr>

<tr>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Approximate Weight</div></td>

<td class="TableText1"><div align="center">7,960 lbs. <br>

(3,610.5 Kg)</div></td>

</tr>

<tr>

<td bgcolor="#CCCCCC" class="TableText1"><div align="center">Dimensions</div></td>

<td class="TableText1"><div align="center">13.08' x 3.41' x4.16'</div></td>

</tr>

</tbody>

</table>

<p><b><br></b></p>

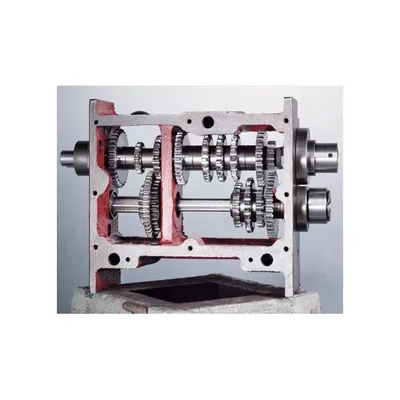

<p><b>FEATURES</b></p>

<ul><li>This model has 4.5” spindle bore, D1-11 Camlock spindle nose, 16” wide bed, 15 HP motor offers great capacity for large work piece. The low speed goes down to 10 rpm offering enough torque for heavy cutting.</li><li>D1-11 camlock spindle</li><li>4.5" spindle bore</li><li>15 HP motor</li><li>12 speeds (10-1,000 rpm)</li><li>Quick change gearbox</li><li>One piece Meehanite cast bed</li><li>Direct selection for inch / metric threads</li><li>Double chucks available as option</li><li>4.5” spindle bore , largest spindle in this size lathes. More choices for different diameter of materials to be machined.</li><li>All headstock gears are hardened and ground made from Chrome-Moly material gives long lasting power and accuracy in machining</li><li>High precision pair of matched angular contact bearings supporting the front end of head stock, and rolling bearing for the rear end support. This arrangement allows high accuracy of the spindle even under heavy cutting conditions.</li><li>Wide range of feeds and threads. Selection done by “pull and lock” handles to avoid slipping in engagement of gears.</li><li>Gears in gearboxes are supported at 3 points with high precision bearings to ensure long lasting feeds and threading operations</li><li>Feed gears are mounted on spline shafts for adequate feed power</li><li>One piece casting bed instead of sheet metal connected legs ensure dampening of vibration and permanent straightness of the bed ways.</li><li>The carriage is coated with TURCITE for better oil retention and for minimum bedwear, longer life.</li><li>The removable gap increases the swing by an extra 9” to accommodate larger work pieces that are short in length</li><li>Jog button is equipped at headstock for easy engagement of gears before cutting</li><li>5” spindle bore, largest spindle in this size lathes. More choices for different diameter of materials to be machined.</li><li>All headstock gears are hardened and ground made from Chrome-Moly material gives long lasting power and accuracy in machining</li><li>High precision pair of matched tapered roller bearings supporting the front end of head stock, and ball bearing for the rear end support. This arrangement allows high accuracy of the spindle even under heavy cutting conditions.</li></ul>

<p><strong> STANDARD EQUIPMENT:</strong></p>

<ul>

<li>4-jaw 16" chuck, face plate (20")</li>

<li>Steady rest (4" – 11.5")</li>

<li>4 ways tool post </li>

<li>Coolant system</li>

<li>Halogen light </li>

<li>4-way carriage stop</li>

<li>Splash guard</li>

<li>16" chuck guard</li>

<li>Tailstock</li>

<li>Follow rest</li>

<li>Tool kit</li>

<li>Rapid transverse on longitudinal (on 100" centers distance and up only)</li>

<li>Wired 220V or 440V</li>

</ul>