<ul>

<li> <strong>Introduced in 2004</strong> the K-Series is a specially designed ironworker with vertical movement on all stations. <strong>The main slide moves up and down to provide optimum results for punching, shearing, notching, and bending without other moving parts.</strong> </li>

<li> Both the punching and notching bases use “T-slots” which provide a solid base for securing the punch tooling, as well as a <strong>wide range of optional and custom-designed tooling</strong>, such as press brakes, vee-notchers, pipe notching, and more! <strong>The 66KB features and integrated 12" Press Brake in place of the notcher, while the 66KBN features both an integrated 4" press brake and a rectangular notcher!<br>

</strong> </li>

<li> <strong>Hydraulic hold-downs for shearing are standard on all models</strong> (except the IW-50K) which integrates into the standard electric back gauge, automating the shearing functions! The adjustable stroke, swing-away stripper, and high speed improve efficiency and allow greater operator control. <strong>The low-pressure mode for tooling alignment and blade changes</strong> provides the utmost safety for the operator, as well as multi-sided blades and adjustable blade gaps. </li>

<li> These models incorporate versatility, efficiency, accuracy, and ease of use at an excellent price. <strong>All K-Series models have a standard 3 Year Parts and 1 Year Labor Warranty!</strong> </li>

<li> <strong>Trilogy Machinery</strong> offers 100% factory-authorized service, support from their Maryland location, and a full OEM spare parts and accessories stock. </li>

<li>Single-Cylinder – Single-Operator – Vertical Design</li>

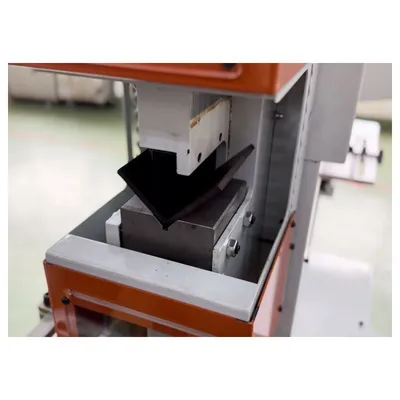

<li>Integrated 4" Press-Brake and Rectangular Notcher – With Guards</li>

<li>Three fully integrated working stations, Shearing, Punching, and Bending</li>

<li>Hydraulic Hold-Down for all Shear Functions</li>

<li>Heavy-duty adjustable punch stripper with visibility window</li>

<li><strong>All Sunrise K-Series Ironworkers come standard with the following:<br>

</strong>

<ul>

<li>40" Touch-and-Cut Electric Back Gauge (Optional extensions to 12' available)</li>

<li>Machined Punch Gauge Table with X-Y Positioning System<strong></strong></li>

<li>Machined Notcher Gauge Table with X-Y Positioning (Except 66KB)</li>

<li>LED Magnetic-Base Work Light</li>

<li>Set of 11 Punches and Dies from 3/8" – 1-1/2"</li>

<li>Structural Die Block for up to 1.5" diameter hole capacity including overhang for angle (oversize tooling is available)</li>

<li>Complete tool kit with Manual, CAD Parts Drawings, Electrical and Hydraulic Schematics printed and loaded on a USB</li>

<li> HD Start Up Video including safety, maintenance, and operation</li>

<li>Hydraulic Shearing Hold-Downs (Standard on IW-66K/KB/KBN)</li>

<li>Extensive List of Optional Equipment: Contact us for Accessory PDF</li>

</ul>

</li>

</ul>