<ul>

<li> <strong>Overview of the SUNRISE Semi-Automatic CNC Ironworker:</strong> </li>

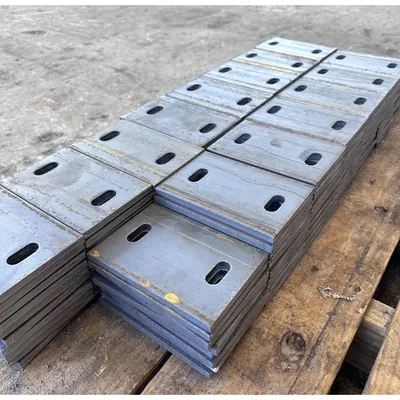

<li> The Semi-Automatic CNC positioning tables from SUNRISE are designed for plate, angle, and channel positioning and feature user-friendly touch-screen interfaces. Factory-installed on any dual-cylinder ironworker or punching machine with a 20” or larger throat dept, they can virtually eliminate your manual layout! </li>

<li> Controlled with an all-flash memory-based Windows computer and a pendant-mounted HD touch-screen monitor, the intuitive yet simple programming enables your operators to learn the controller in minutes. </li>

<li> <strong>Execution</strong>: The operator loads the program, positions the material against the CNC-controlled X and Y stops, and initiates the punch.. While holding the plate in position, they step on the foot pedal, punching the hole. Then, the CNC-controller X and Y back gauge automatically moves to its next position. </li>

<li>Semi-Automatic CNC Dual-Cylinder – Dual-Operator – Ironworker</li>

<li>Hydraulic Punch Stripper</li>

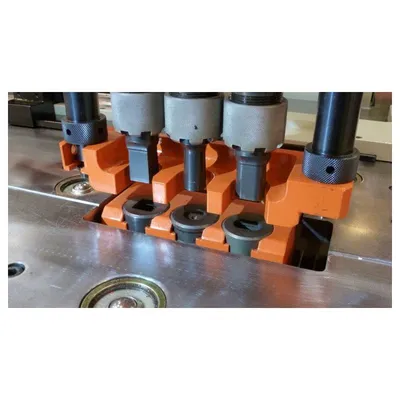

<li>Triple Punch Attachment – 1.5" Middle Punch – 1.125" Capacity Side Punches</li>

<li>Hydraulic Angle and Plate Shear Hold Downs</li>

<li>120" x 16" Table</li>

<li>15" Touch-Screen controller, offline software, DXF/NC1 Import</li>

<li><strong>SUNRISE Ironworkers include, as standard, the most complete set of features of any Ironworker brand:

</strong>

<ul>

<li>40" Touch-and-Cut Electric Back Gauge – Can use with the CNC Shear</li>

<li>Machined Notcher Gauge Table with X-Y Positioning</li>

<li>LED Magnetic-Base Work Light</li>

<li>Set of 11 Punches and Dies from American Punch – 3/8" – 1-1/2"</li>

<li>Reversible Structural Die Block for up to 2" diameter hole capacity including overhang for angle and channel flange punching</li>

<li>Complete tool kit with Manual, CAD Parts Drawings, Electrical and Hydraulic Schematics printed and loaded on a USB</li>

<li>Full tank of Hydraulic Oil</li>

<li>HD Start-Up Video including safety, maintenance, and operation – Including QR codes to easily access on the side of each machine.</li>

<li>Extensive List of Optional Equipment: Contact us for Accessory PDF</li>

</ul>

</li>

<li><strong>SUNRISE</strong> offers one of the widest ranges of CNC options today, including semi and fully-automatic punches, automatic shearing, and new complete processing systems.</li>

</ul>

<p><b>STANDARD FEATURES:</b></p>

<ul>

<li> –<strong>Mitsubishi Servo Motors</strong> – The best Japanese brushless servo motor in the business with 590”/min speed and positioning accuracy of 0.004” powered by Mitsubishi servo amplifiers in a fan-cooled cabinet. </li>

<li> <strong>– NIASA Ball-Screw—This High-Torque-Rated ball-screw ensures accuracy even while gauging heavy steel parts. It is coupled</strong> with proximity sensors for machine calibration and travel range detection. </li>

<li> –<strong>Advantech Windows PC Controller</strong> – 15” HD touchscreen, built-in templates, off-line software, ethernet, WiFi, DXF/NC1 import, and more! </li>

<li> –<strong>Hydraulic Stripper</strong> – Your material is clamped with proportionate pressure to ensure the best hole quality. Coupled with an adjustable stroke hydraulic cylinder for up to 30 stroke per minute at ¾” travel. </li>

<li> <strong>-Machined-Flat Gauging Table </strong>– Features all-steel design, replaceable ball transfers, and X/Y gauges. The entire frame is bolted to a machined steel tube, secured with leveling feet. </li>

</ul>