<p><b>SPECIFICATIONS:</b></p>

<table cellspacing="0" cellpadding="0" border="1" width="520">

<tbody style="text-align: center;">

<tr>

<td valign="middle" bgcolor="#333333" class="Title_white_bold"><div align="center"><span style="color: rgb(255, 255, 255);"><b>MODEL</b></span></div></td>

<td width="257" valign="middle" bgcolor="#333333" class="TableText"><div align="center" class="Title_white_bold">

<div align="center"><span style="color: rgb(255, 255, 255);"><b>G4P 25/13

</b></span></div>

</div></td>

</tr>

<tr>

<td valign="middle" bgcolor="#cccccc" class="TableText"><div align="center">Working Length</div></td>

<td valign="middle" class="TableText"><div align="center">102"</div></td>

</tr>

<tr>

<td width="257" valign="middle" bgcolor="#cccccc" class="TableText"><div align="center">Pre-bending capacity 3x TRD</div></td>

<td valign="middle" class="TableText"><div align="center">3/8"</div></td>

</tr>

<tr>

<td valign="middle" bgcolor="#cccccc" class="TableText"><div align="center">Max rolling capacity 3x TRD</div></td>

<td valign="middle" class="TableText"><div align="center">1/2"</div></td>

</tr>

<tr>

<td valign="middle" bgcolor="#cccccc" class="TableText"><div align="center">Top roll diameter</div></td>

<td valign="middle" class="TableText"><div align="center">10.63"</div></td>

</tr>

<tr>

<td valign="middle" bgcolor="#cccccc" class="TableText"><div align="center">Bottom roll diameter</div></td>

<td valign="middle" class="TableText"><div align="center">9.80"</div></td>

</tr>

<tr>

<td valign="middle" bgcolor="#cccccc" class="TableText"><div align="center">Power</div></td>

<td valign="middle" class="TableText"><div align="center">15 HP</div></td>

</tr>

<tr>

<td valign="middle" bgcolor="#cccccc" class="TableText"><div align="center">Weight</div></td>

<td valign="middle" class="TableText"><div align="center">16,000 lbs.</div></td>

</tr>

</tbody>

</table>

<p>*The specifications above are based on steel with a yield point of 36,000 PSI</p>

<table cellspacing="0" cellpadding="0" border="1" width="520">

<tbody style="text-align: center;">

<tr>

<td colspan="2" valign="middle" bgcolor="#333333" class="Title_white_bold"><div align="center" class="Title_white_bold">

<div align="center"><span style="color: rgb(255, 255, 255);"><b>CONICAL BENDING ANGLE

</b></span></div>

</div></td>

</tr>

<tr>

<td width="257" valign="middle" bgcolor="#cccccc" class="TableText"><div align="center">3°</div></td>

<td width="257" valign="middle" class="TableText"><div align="center">0%</div></td>

</tr>

<tr>

<td valign="middle" bgcolor="#cccccc" class="TableText"><div align="center">5°</div></td>

<td valign="middle" class="TableText"><div align="center">90%</div></td>

</tr>

<tr>

<td valign="middle" bgcolor="#cccccc" class="TableText"><div align="center">15°</div></td>

<td valign="middle" class="TableText"><div align="center">75%</div></td>

</tr>

<tr>

<td valign="middle" bgcolor="#cccccc" class="TableText"><div align="center">30°</div></td>

<td valign="middle" class="TableText"><div align="center">60%</div></td>

</tr>

<tr>

<td valign="middle" bgcolor="#cccccc" class="TableText"><div align="center">60°</div></td>

<td valign="middle" class="TableText"><div align="center">50%</div></td>

</tr>

<tr>

<td valign="middle" bgcolor="#cccccc" class="TableText"><div align="center">70°</div></td>

<td valign="middle" class="TableText"><div align="center">40%</div></td>

</tr>

</tbody>

</table>

<p><b><br>FEATURES:</b></p>

<ul>

<li><strong>ROBUST MACHINE FRAMES: </strong>At Gator, our machine bodies are meticulously designed and reinforced to minimize plate deformation. Constructed from ST-52 quality steel, the machine frames are built for exceptional strength and durability. The entire body undergoes CNC machining, ensuring precise surface finishes and perfect parallelism across all axes. This advanced production process not only enhances the longevity of the machine but also ensures the precision of its critical components.<br>

</li>

<li><strong>BEARING GUIDANCE SYSTEM:</strong> Our rolls are equipped with spherical roller bearings for superior guidance. This advanced bearing system requires minimal lubrication and guarantees long-term precision and reliability.</li>

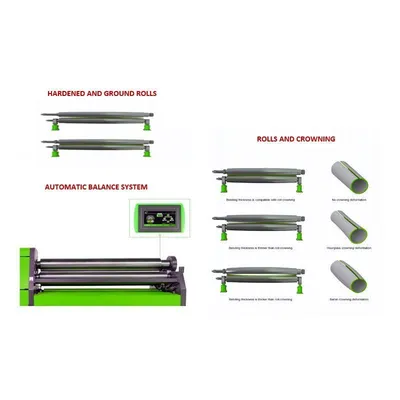

<li><strong>HARDENED AND GROUND ROLLS:</strong> Our rolls, made from SAE 1050 (CK45) forged steel, are precision-machined using CNC technology to ensure optimal quality. Each roll undergoes induction hardening for enhanced durability and performance. </li>

<li><strong>AUTOMATIC BALANCE SYSTEM:</strong> To achieve precise bending, maintaining the parallelism of the bottom roll is crucial. Our machines are equipped with a PLC electronic balance system that automatically adjusts the parallelism with the press of a button on the control panel. This ensures accurate and consistent bending performance. <br>

</li>

<li><strong>ROLLS AND CROWNING</strong><br>

The rolls are crucial components of plate roll machines, and their quality significantly impacts performance. Many market machines feature smaller diameter rolls that can deform during pre-bending, leading to flat spots on the plate edges.</li>

<li>At Gator, we address this with larger diameter rolls made from high-quality forged steel. These rolls are precisely machined using advanced CNC lathes. Their working surfaces are CNC induction hardened and polished to a hardness of HRC 54-58, with hardness tested at multiple points to ensure uniformity. This robust construction allows for a minimum bending diameter of 3 times the top roll diameter.</li>

<li>To counteract roll deflection during pre-bending, our rolls are machined with a crown. We also offer custom crowning designs tailored to different materials or thicknesses at no additional charge, ensuring optimal performance for various applications.<br>

</li>

<li><strong>ADJUSTABLE BOTTOM ROLL PRESSURE:</strong> All Gator plate bending machines feature adjustable bottom roll pressure. This functionality allows for precise bending of materials with varying thicknesses and qualities, ensuring accurate and consistent results across different applications.</li>

<li><strong>Top Roll Hydraulic Drop End and Upward Mobile Top Roll:</strong> GATOR plate bending machines come standard with a hydraulic drop end and an upward mobile top roll. This feature facilitates easy removal of the bent material, enhancing operational efficiency and convenience for the operator.<br>

</li>

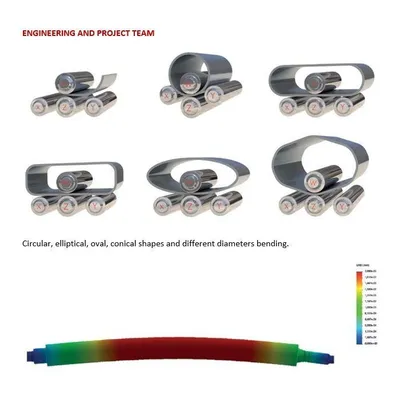

<li><strong>CONICAL BENDING SYSTEM</strong><br>

Our robust machine body, along with the large side rolls and angular bottom roll, effortlessly handles wide-angle and various diameter conical parts. We’ve streamlined conical bending with an independent bottom roll and side rolls that can move in two directions, allowing precise control over the bending angle.</li>

<li>However, it's important to note that if the bending angle exceeds 3 degrees, the performance may decrease due to imbalanced load distribution on the machine’s bearings. As the bending angle increases, there can be up to a 50% reduction in the effective length and thickness of the material.<br>

</li>

<li><strong>CONICAL BENDING AUXILIARY PARTS:</strong> In addition to the central conical support roller, the GTR series features adjustable auxiliary rollers on each side of the machine. These side rollers provide enhanced support and flexibility, ensuring precise and consistent conical bending across a range of applications.<br>

</li>

<li><strong>INFRARED SAFETY SENSOR: </strong>Our GTR series machines are equipped with infrared sensors that detect IR light emitted from objects within their field of view. This system enhances both operator and equipment safety by preventing potential damage, thereby increasing overall work and worker protection.</li>

<li><strong>HYDRAULIC MOTOR AND PLANETARY GEAR BOXES:</strong> The Four-Roll GTR series simplifies material bending with fewer steps, thanks to its high-torque drive system. Each roll is powered by independent hydraulic motors and planetary gearboxes, all aligned on the same axis to ensure maximum power transfer to the sheet with no loss of force. This design minimizes the risk of material slippage during pre-bending, preventing potential damage and enhancing safety.</li>

<li><strong>PLANETARY GUIDE SYSTEM: </strong>The side rolls are mounted on hydraulic pistons that move in a planetary motion, allowing for precise vertical adjustments. The Planetary Guide System ensures a greater distance between the top and bottom rolls compared to other systems. This increased distance accommodates a wider range of material thicknesses and strengths, making it easier to pre-bend and roll heavy plates.</li>

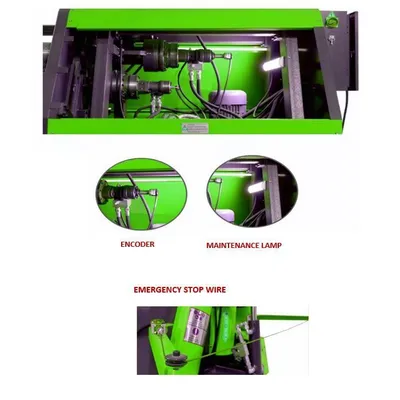

<li><strong>ENCODER</strong>: Our machines feature a hidden encoder designed to record rotational movement accurately while being protected against damage. This encoder ensures precise monitoring and control of turning operations.</li>

<li><strong>MAINTENANCE LAMP: </strong>We have made maintenance easier with an interior lighting lamp that is manageable in the touch screen menu.</li>

<li><strong>EMERGENCY STOP WIRE:</strong> The emergency stop wire is a crucial safety feature designed to halt the machine instantly, ensuring the safety of the operator and protecting the machine's system. All GTR series models are equipped with a safety cable switch to provide reliable and immediate emergency stop functionality.</li>

<li><strong>OIL COOLER: </strong>Oil cooling systems applied to machines are used to improve machine performance and prevent damage that may occur due to over-heating. These systems are typically designed to cool the oil during machine operation, thus preventing the oil from deteriorating due to temperature while performing its function. This system is presented as standard in our GTR 310 and above models.</li>

<li><strong>CENTRAL OILING SYSTEM: </strong>The automatic lubrication system enhances the service life of our machines and boosts productivity by eliminating the need for manual lubrication. This feature ensures smooth operation over an extended period, thereby extending the machines' longevity and helping businesses achieve greater efficiency. This system is a standard feature in our GTR 310 models and above.<br>

</li>

<li><strong>ROTARY CENTRAL SUPPORT AND CRANE EQUIPMENT:</strong> Our G4P series with the 90° rotating lift system, makes materials easy to be carried or lifted by cranes or other equipment. With this equipment, the machine lift system is prevented from taking any damage.</li>

<li><strong>OVERHEAD TOP SUPPORT:</strong> It is used for supporting materials with large diameters without the need for crane use during ending.<br>

</li>

<li><strong>ENGINEERING AND PROJECT TEAM</strong></li>

<li>All our machines are crafted by skilled engineers at our factory, utilizing advanced 3D engineering technology and comprehensive mechanical analysis. Each mechanical and electronic system is meticulously designed and tested by specialists in their respective fields.</li>

<li>We prioritize components known for their long-term reliability, ensuring that our projects are developed with durability in mind. Our commitment to continuous improvement drives us to surpass expectations and enhance our work every day.<br>

</li>

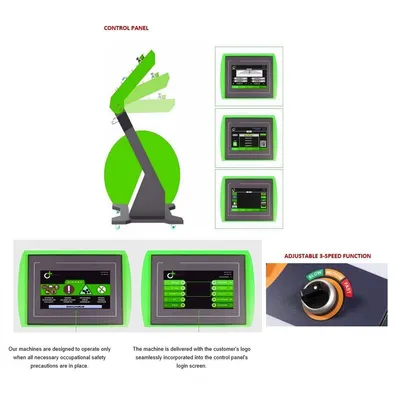

<li><strong>CONTROL PANEL</strong>

<ul>

<li>3-Stage Angularly Adjustable Control Panel: Offers ease of use for the operator with customizable angles.</li>

<li>Mobile Control Panel: Equipped with wheels for easy relocation.</li>

<li>Adjustable Keypad: Designed for both horizontal and vertical machine use.</li>

<li>Sound-Light Buzzer Warning System: Provides clear alerts and notifications.</li>

<li>Bending Calculation Page: Computes the required arc and depth for precise bending control.</li>

<li>Digital Display: Shows machine operating hours.</li>

<li>Multi-Lingual Support: Available in English, German, Spanish</li>

<li>Capacity Tables: Accessible directly from the control panel for convenience.</li>

<li>Transparent Protection Cover: Safeguards the control panel while allowing visibility</li>

</ul>

</li>

<li>We are proud to be the first company to make automation a standard feature in our machines. By integrating the Numerical Control (NC) System—developed with GATOR's expertise—into our Profile, Pipe, and Sheet Bending Machines, we enhance both mass production and precision, setting a new standard in productivity.</li>

<li><strong>ADJUSTABLE 3-SPEED FUNCTION:</strong> The G4P plate rolling machines come with a three-speed feature. This allows for enhanced versatility and control, enabling users to select the optimal speed for various materials and bending tasks.</li>

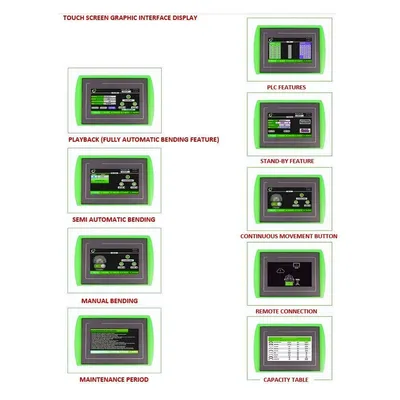

<li><strong>TOUCH SCREEN GRAPHIC INTERFACE DISPLAY: </strong>Directing the machine for more precise bending is now effortless with our user-friendly graphic interface and advanced technology. The 7" and 10" touch screen displays enable you to perform a wide range of essential processes with ease.

<ul>

<li><strong>PLAYBACK (FULLY AUTOMATIC BENDING FEATURE):</strong> Bending parts with consistent precision and in the same position is now simpler and more efficient. By uploading the shapes and desired diameters of the parts to the system just once, you can achieve accurate bends without requiring an experienced operator. This approach not only saves time but also ensures greater precision in your bending processes.</li>

<li><strong>SEMI AUTOMATIC BENDING:</strong> You can program the required shapes and diameters directly into the system based on the material characteristics, allowing the rolls to be positioned automatically. This results in more precise and higher-quality bends.</li>

<li><strong>MANUAL BENDING:</strong> Gator, with its manual bending feature, enables the bending of non-continuous bending by expert operators.</li>

<li><strong>MAINTENANCE PERIOD:</strong> It has the feature of informing the operator about the maintenance procedure to be done when the maintenance period comes.</li>

<li><strong>PLC FEATURES: </strong>We can diagnose possible failures faster and easier, reach a solution in a shorter time, and provide easy maintenance with the control page displaying the inputs and outputs between the PLC and the control panel.</li>

<li><strong>STAND-BY FEATURE:</strong> We’ve introduced a unique Stand-By feature that enhances the machine's versatility. While bending material, you can pause the operation, modify the program steps, and then resume automatic bending from the exact point where you left off with the updated program. This allows for more precise and higher-quality bending results.</li>

<li><strong>CONTINUOUS MOVEMENT BUTTON:</strong> All machines have a continuous movement button on the control panel. In that way, the continuous movement of rolls can be obtained during the bending</li>

<li><strong>REMOTE CONNECTION:</strong> We understand that time is a crucial value in today’s world. With this in mind, we leverage cutting-edge technology to support our valued customers effectively. In the event of a machine malfunction, we establish an online connection to address the issue promptly. Our remote access feature allows us to provide quick solutions by intervening directly in the machines.</li>

<li><strong>CAPACITY TABLE:</strong> All our profile and pipe bending machines, as well as our 4-roll plate bending machines, come with integrated capacity tables in their control panels. Each machine features its own specific capacity table, which we are proud to offer to our business partners for greater convenience and precision.<br>

</li>

</ul>

</li>

</ul>

<p><b> STANDARD FEATURES:</b></p>

<ul>

<li><strong>7" Multi-Functional Touch Screen:</strong> Intuitive interface for easy operation and control.</li>

<li><strong>NC Control:</strong> Offers manual, semi-automatic, and fully automatic modes.</li>

<li><strong>Three-Speed Feature:</strong> Provides versatile operation speeds for different tasks.</li>

<li><strong>Bearing Guidance System:</strong> Ensures smooth and precise performance.</li>

<li><strong>ST-52 Quality Steel Frame and Components:</strong> Delivers durability and strength.</li>

<li><strong>Bottom Roll Pressure Adjustment</strong>: Allows for fine-tuning of material handling.</li>

<li><strong>Hydraulic Drop End and Top Roll</strong>: Facilitates efficient and flexible operation.</li>

<li><strong>Automatic Balance System:</strong> One-button operation for optimal balancing.</li>

<li><strong>Conical Bending System:</strong> Enables conical shaping with precision.</li>

<li><strong>Conical Bending Auxiliary Parts:</strong> Supports the conical bending process.</li>

<li><strong>Hydraulic Motor and Planetary Gearbox-Driven Rolls:</strong> Ensures robust and reliable power transmission.</li>

<li><strong>Planetary Guide System:</strong> Provides enhanced guidance and stability.</li>

<li><strong>Hidden Encoder</strong>: Records rotational movement and protects against damage.</li>

<li><strong>Overload Protection System:</strong> Safeguards the machine from excessive strain.</li>

<li><strong>Continuous Turning with One Button:</strong> Streamlines the turning process.</li>

<li><strong>Induction-Hardened and Ground Rolls):</strong> Offers durability and smooth operation.</li>

<li><strong>Three-Stage Mobile Control Pane</strong>: Separately mounted for ease of access.</li>

<li><strong>Online Remote Connection:</strong> Enables remote monitoring and support.</li>

<li><strong>Oil Cooler:</strong> Maintains optimal operating temperatures.</li>

<li><strong>Auto Lubrication System:</strong> Ensures consistent lubrication and reduced maintenance.</li>

<li><strong>Formula Page:</strong> Calculates radius and depth for precise bending.</li>

<li><strong>Sound-Light Buzzer Warning System:</strong> Alerts operators to potential issues.</li>

<li><strong>Emergency Stop Wire</strong>: Surrounds the machine for quick shutdown in emergencies.</li>

<li><strong>Maintenance Warning Page</strong>: Displays upcoming maintenance schedules.</li>

<li><strong>Alarm Page</strong>: Provides real-time warnings and alerts for machine status.</li>

<li><strong>CE Certification</strong>: Meets European safety and quality standards.</li>

<li><strong>Transparent Protection Cover</strong>: Safeguards the control panel while allowing visibility. </li>

</ul>

<p><b> OPTIONAL ITEMS:</b></p>

<ul>

<li>Side supports (both sides)</li>

<li>Rear Laser Emergency Stop Barrier: Enhances safety with a laser-activated emergency stop system.</li>

<li>Variable Speed Feature: Allows adjustable speed settings to match different operational needs.</li>

<li>Overhead Top Support: Offers additional stability and support for materials.</li>

<li>Hydraulic Side Supports (Both Sides): Ensures secure material handling and stability during operation.</li>

<li>Material Feeding Table: Facilitates smooth and efficient material input.</li>

<li>Material Output Table: Provides a convenient platform for material discharge.</li>

<li>Changeable Top Roll: Allows for easy customization and replacement of top rolls.</li>

<li>Multi-Color Options: Provides aesthetic customization with various color choices.</li>

<li>Custom Logo Application with Laser Cutting: Enables personalized branding through precise laser-cut logos.<br>

</li>

</ul>