<p><b>TECHNICAL SPECIFICATIONS</b></p>

<table cellspacing="0" cellpadding="0" border="1" width="520">

<tbody style="text-align: center;">

<tr>

<td width="179" valign="middle" bgcolor="#333333" class="Title_white_bold"><div align="center"><span style="color: rgb(255, 255, 255);"><b>MODEL</b></span></div></td>

<td width="335" valign="middle" bgcolor="#333333" class="TableText"><div align="center"><span style="color: rgb(255, 255, 255);"><b><span class="Title_white_bold" style="color: rgb(255, 255, 255);">FALCON CUT 550</span></b></span></div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">Tube (Diameter)</div></td>

<td valign="middle" class="TableText"><div align="center">Ø 1.57" – 21.65"</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" width="179" valign="middle" class="TableText"><div align="center">Square (Height x Width)</div></td>

<td valign="middle" class="TableText"><div align="center">1.57" x 1.57" – 21.65" x 21.65"</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">Material Length</div></td>

<td valign="middle" class="TableText"><div align="center">8' 2.5" – 41' 4"</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">Applicable Types</div></td>

<td valign="middle" class="TableText"><div align="center">Circular, square, rectangular, elliptical, D-shaped, T-shaped, H-shaped, channel steel, etc.</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">Applicable Materials</div></td>

<td valign="middle" class="TableText"><div align="center">Stainless steel, carbon steel, galvanized tube, copper tube, aluminum tube, aluminum alloy</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">Workbench Height</div></td>

<td valign="middle" class="TableText"><div align="center">51.18" above floor</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">Workbench Load</div></td>

<td valign="middle" class="TableText"><div align="center">4,850 lbs.</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">Workbench Type</div></td>

<td valign="middle" class="TableText"><div align="center">Semi-automatic loading</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">Rated Power</div></td>

<td valign="middle" class="TableText"><div align="center">160 HP</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">Power Demand</div></td>

<td valign="middle" class="TableText"><div align="center">AC 380±5% V</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">Equipment Noise</div></td>

<td valign="middle" class="TableText"><div align="center">65 dB</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">File Format</div></td>

<td valign="middle" class="TableText"><div align="center">STP, IGS, .NC, etc.</div></td>

</tr>

</tbody>

</table>

<p><b>LASER PARAMETERS:</b></p>

<table cellspacing="0" cellpadding="0" border="1" width="520">

<tbody style="text-align: center;">

<tr>

<td width="257" valign="middle" bgcolor="#333333" class="Title_white_bold"><div align="center"><span style="color: rgb(255, 255, 255);"><b>MODEL</b></span></div></td>

<td width="257" valign="middle" bgcolor="#333333" class="TableText"><div align="center"><span style="color: rgb(255, 255, 255);"><b><span class="Title_white_bold" style="color: rgb(255, 255, 255);">FALCON CUT 550</span></b></span></div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">Output Power</div></td>

<td valign="middle" class="TableText"><div align="center">12 kW</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" width="257" valign="middle" class="TableText"><div align="center">Emission Wavelength</div></td>

<td valign="middle" class="TableText"><div align="center">1,070 nm</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">Output Connector</div></td>

<td valign="middle" class="TableText"><div align="center">Q+</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">Operation Mode</div></td>

<td valign="middle" class="TableText"><div align="center">Continuous / Modulated</div></td>

</tr>

</tbody>

</table>

<p><b>MOTION SYSTEM PARAMETERS:</b></p>

<table cellspacing="0" cellpadding="0" border="1" width="520">

<tbody style="text-align: center;">

<tr>

<td width="96" valign="middle" bgcolor="#333333" class="Title_white_bold"><div align="center"></div></td>

<td width="208" valign="middle" bgcolor="#333333" class="Title_white_bold"><div align="center"><span style="color: rgb(255, 255, 255);"><b>MODEL</b></span></div></td>

<td width="208" valign="middle" bgcolor="#333333" class="TableText"><div align="center"><span style="color: rgb(255, 255, 255);"><b><span class="Title_white_bold" style="color: rgb(255, 255, 255);">FALCON CUT 550</span></b></span></div></td>

</tr>

<tr>

<td width="96" rowspan="6" valign="middle" bgcolor="#333333" class="Title_white_bold"><div align="center"><span style="color: rgb(255, 255, 255);"><b>TRANSMISSION SYSTEM</b></span></div></td>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">Transmission Type</div></td>

<td valign="middle" class="TableText"><div align="center">Precision gear and rack transmission</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" width="208" valign="middle" class="TableText"><div align="center">Feeding Model</div></td>

<td valign="middle" class="TableText"><div align="center">Follow-up cutting</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">Idle Speed (Max)</div></td>

<td valign="middle" class="TableText"><div align="center">98.4 ft/min</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">Cutting Speed (Max)</div></td>

<td valign="middle" class="TableText"><div align="center">65.6 ft/min</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">Acceleration Approach Speed (Max)</div></td>

<td valign="middle" class="TableText"><div align="center">0.98 g</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">Repetitive Positioning Accuracy</div></td>

<td valign="middle" class="TableText"><div align="center">±0.002" / 3.28 ft</div></td>

</tr>

<tr>

<td rowspan="3" valign="middle" bgcolor="#333333" class="Title_white_bold"><div align="center"><span style="color: rgb(255, 255, 255);"><b>AUXILIARY SYSTEM</b></span></div></td>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">Cutting Head for Fiber</div></td>

<td valign="middle" class="TableText"><div align="center">Capacitive follow-up focusing</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">Auxiliary Gas</div></td>

<td valign="middle" class="TableText"><div align="center">Dual pressure air path; automatic switching of air, nitrogen, and oxygen</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">Cooling System</div></td>

<td valign="middle" class="TableText"><div align="center">Specified dual temperature/dual pump water cooling unit with purification system</div></td>

</tr>

<tr>

<td rowspan="3" valign="middle" bgcolor="#333333" class="Title_white_bold"><div align="center"><span style="color: rgb(255, 255, 255);"><b>LOADING SYSTEM</b></span></div></td>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">6.5-meter Automatic <br>

Loading Machine</div></td>

<td valign="middle" class="TableText"><div align="center">Max. 21.33 ft / 2,425 lbs.</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">9.5-meter Automatic <br>

Loading Machine</div></td>

<td valign="middle" class="TableText"><div align="center">Max. 31.17 ft / 3,530 lbs.</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">12.5-meter Automatic <br>

Loading Machine</div></td>

<td valign="middle" class="TableText"><div align="center">Max. 41.01 ft / 4,850 lbs.</div></td>

</tr>

<tr>

<td rowspan="4" valign="middle" bgcolor="#333333" class="Title_white_bold"><div align="center"><span style="color: rgb(255, 255, 255);"><b>UNLOADING SYSTEM OPTIONS</b></span></div></td>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">1.5-2.8-meter Unloading Machine</div></td>

<td valign="middle" class="TableText"><div align="center">For finished products with a length of 4.92 ft to 9.19 ft</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">1.5-4.5-meter Unloading Machine (Optional)</div></td>

<td valign="middle" class="TableText"><div align="center">For finished products with a length of 4.92 ft to 14.76 ft, movable and spliceable</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">9.5-meter Automatic <br>

Unloading Machine (Optional)</div></td>

<td valign="middle" class="TableText"><div align="center">31.17 ft / 3,530 lbs.</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">12.5-meter Automatic <br>

Unloading Machine (Optional)</div></td>

<td valign="middle" class="TableText"><div align="center">41.01 ft / 4,850 lbs.</div></td>

</tr>

</tbody>

</table>

<p><b>FEATURES:</b></p>

<ul>

<li>All-in-One Laser Cutting Machine, 21.65” Capacity<br>

Round pipe – Square tube – I-beam – Flat bar - Angle</li>

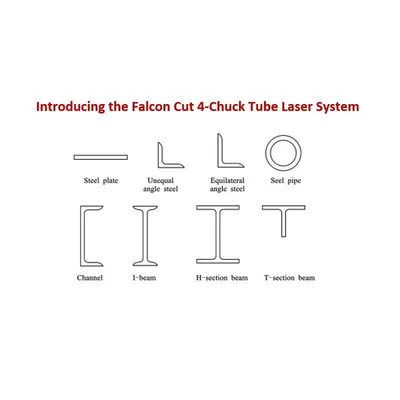

<li><strong>Introducing the Falcon Cut 4-Chuck Tube Laser System</strong></li>

<li>The Falcon Cut is a cutting-edge, all-in-one tube laser cutting machine that seamlessly blends German engineering and precision with outstanding versatility and speed. Designed to process a wide range of materials, including square tubes, round pipes, flat bars, I-beams, angles, channels, and more, the Falcon Cut sets a new benchmark in the tube laser cutting industry.</li>

<li>At the heart of the Falcon Cut is the innovative 4-chuck system, engineered to offer unmatched stability, precision, and efficiency. Unlike traditional systems, the 4-chuck mechanism provides superior clamping strength and precision, allowing the machine to handle even the most complex shapes and heavy-duty materials with ease. The system also ensures zero-waste processing, maximizing material usage and minimizing scrap. With this advanced chuck design, the Falcon Cut achieves faster cycle times while maintaining the highest cutting quality.</li>

<li>In addition to its advanced chuck system, the Falcon Cut operates at remarkable cutting speeds, optimizing production times and improving overall efficiency. Whether working with carbon steel, stainless steel, aluminum, or other materials, the Falcon Cut delivers consistently high-quality results, providing exceptional performance for both small and large production runs.</li>

<li>The Falcon Cut is the result of a strategic partnership between GATOR and German Engineering, combining decades of expertise in laser cutting technology. This collaboration ensures that the Falcon Cut is not only a high-performance machine but also one that is tailored to meet the most demanding industrial standards. Together, GATOR and Craft Stahl GmbH bring reliability, durability, and cutting-edge technology to every Falcon Cut machine.</li>

<li>Crafted with German engineering standards, the Falcon Cut embodies reliability, durability, and cutting-edge technology, making it the ideal choice for manufacturers seeking a high-performance, versatile, and efficient solution for their tube cutting needs. With its combination of speed, precision, and flexibility, the Falcon Cut ensures manufacturers can meet demanding production schedules while maintaining top-tier quality.<br>

</li>

<li><strong>Customized for Heavy-Duty Tube Cutting</strong></li>

<li>Ultra-Large Cutting Range: Equipped with both a square and round structure chuck, this system can cut pipes with a maximum diameter equal to the maximum side length of a square pipe, offering users more flexibility in processing.</li>

<li>Comprehensive Protection for Heavy-Duty Materials: Supports workpieces up to 4,850 lbs (2,200 kg).</li>

<li>Enhanced Chuck Design: The chuck provides sufficient strength, rigidity, and shock absorption. This design effectively suppresses vibrations during the cutting of extra-long and heavy steel pipes.</li>

<li>Support Stand Design: The support stand moves with the rotation of the pipe, adjusting its position vertically to maintain support, preventing vertical swinging that could cause cutting inaccuracies.</li>

<li>Zero Scrap Processing: The chuck structure allows for forward or backward movement of the material during the cutting of the last piece, achieving zero-waste cutting.</li>

<li><strong>High Cutting Precision</strong></li>

<li>Interpolation Follow-up: Calculates the Z-axis interpolation coordinates during cutting, allowing the height adjuster to follow within a small range, achieving faster and more precise cutting.</li>

<li>Dual Y Cutting: Small holes on heavy pipes can be machined without moving the pipe material, improving the cutting precision for small holes.</li>

<li>Built-in Air Pressure Monitoring on the Laser Head: Monitors gas flow output in real-time during cutting, effectively reducing the impact of insufficient or excessive air pressure on cut surface quality.</li>

<li><strong>High Cutting Efficiency</strong></li>

<li>Four Chucks Intelligent Cooperation: During cutting, the system allows for parallel operation of loading the next round and unloading the previous one, enhancing process efficiency.</li>

<li>Maximum ±45° Bevel Cutting: Capable of forming bevels up to ±45 degrees in a single pass, reducing the need for additional beveling operations and thus increasing efficiency.</li>

<li>Integrated Process (Optional): Integrates operations such as tapping, riveting, cutting, and marking into the laser cutting process, significantly improving machining efficiency.</li>

<li>Fully Automatic Loading and Unloading System: Enables smooth loading and unloading of heavy pipes with varying lengths, sizes, and shapes, reducing the risk of scratches between workpieces. The system interfaces seamlessly with the machine tool for semi-automatic or fully automatic production, reducing work time and improving efficiency.</li>

<li><strong>Machine Bed</strong>: The machine bed features an independently developed, specialized structural design that is processed integrally in a single operation. This ensures high precision, exceptional rigidity, and strong seismic resistance. The innovative lubrication system significantly enhances the long-term service life of the machine bed. The flexible and intelligent servo support mechanism provides optimal support during high-efficiency cutting processes.</li>

<li>Side-Mounted Machine Bed: The machine bed follows the design standards of heavy-duty machine tools and is welded in segments. Utilizing structural dynamic design principles and variable analysis techniques based on the finite element method, it possesses outstanding dynamic and static characteristics.</li>

<li>Frame Structure: The frame is welded using high-quality steel plates and tubes, undergoing independent welding, secondary aging treatment, and precision machining on a large gantry milling machine.</li>

<li>Seismic Resistance and High Rigidity: These design and processing methods guarantee superior seismic resistance and high rigidity for the machine tool.<br>

Servo Support Mechanism: The machine bed is equipped with multiple sets of servo support mechanisms, each controlled by an independent servo motor for lifting. This allows for real-time height adjustment based on the pipe's rotation, ensuring perfect support during the cutting process.

<ul>

<li>The servo mechanism is highly compatible, suitable for both large and small pipes, and can self-center various pipe materials. It ensures smooth feeding and is cast as a single unit, providing robust support and weight-bearing capacity.</li>

<li>Fixed on the machine bed, the servo material support helps handle heavier pipes, resulting in minimal deformation even after long-term use.</li>

</ul>

</li>

<li>Advanced Lubrication System: Based on years of industry research and development, a new lubrication method has been created. Using rated data such as quantitative and regional lubrication methods, this precise system improves human-machine interaction and the operational experience, extending the equipment's overall service life.<br>

</li>

<li><strong>Chuck Construction: </strong>The chuck of the laser tube cutting machine is independently designed, developed, and manufactured. It features an integrated built-in drive structure that ensures high efficiency and stability.</li>

<li>Increased Efficiency: When paired with a full servo bus control system, the efficiency of this chuck is approximately twice that of standard pipe cutting machines.</li>

<li>Enhanced Passing Capacity: The square hole design improves the chuck's ability to pass larger pipes.</li>

<li>Compact Design: With reduced scrap material and a smaller axial dimension, the rear chuck can extend into the internal control.</li>

<li>Intelligent Clamping Force Adjustment: The clamping force can be automatically adjusted to suit various tube processing needs.</li>

<li>Full-Stroke Clamping: This feature ensures automatic and precise centering, eliminating the need for manual adjustments.</li>

<li>Eight-Cylinder Structure: The chuck uses an eight-cylinder structure, providing twice the clamping force of standard chucks.</li>

<li>Precision-Ground Gear Transmission: This mechanism offers stronger power, reduced active inertia, and higher efficiency.</li>

<li>High Dustproof Rating: The chuck’s high dustproof rating ensures enhanced stability during operation.</li>

<li>3-Chuck Configuration (Optional): A three-chuck configuration is available to meet the customer’s specific needs.<br>

</li>

<li><strong>Side Hanging 4-Chuck Construction</strong></li>

<li>Facilitates Loading and Unloading: The side-hanging chuck structure of the heavy-duty tube cutting machine enhances the efficiency of loading and unloading processes.</li>

<li>Designed for Heavy-Duty Tubes: The side-hanging chuck structure features a lower body design, making it especially suitable for handling heavy-duty tubes.</li>

<li><strong>Support and Loading/Unloading for Ultra-Large Tubes</strong></li>

<li>Follow-up Support Structure: For ultra-large tubes, the follow-up support structure does not need to be excessively high. This design is safer, offers a large load-bearing capacity, and allows for more flexible flipping.</li>

<li>Push-Type Loading: The push-type loading system is designed to easily process oversized and overweight tubes.</li>

<li>Push-Type Unloading: The push-type unloading system ensures that oversized and overweight tubes are effectively pushed, picked up, and transported to the receiving position.<br>

</li>

<li><strong>Drive System</strong></li>

<li>High-Precision Gears and Racks: The system uses high-precision gears and racks, processed through precision cutting and grinding.</li>

<li>Ultra-High Matching Precision: This ensures a high bite rate, resulting in smoother and quieter rotation.</li>

<li>Compact Structure: The compact design effectively reduces driving torque and suppresses vibration.</li>

<li>Dual Drive Gantry Motion System: The dual drive system provides higher acceleration and better deceleration performance.<br>

</li>

<li><strong>Double-Sided Gantry Pillars</strong></li>

<li>Chain-Type Cross Conveyor: The chain-type cross conveyor consists of multiple rows of chain conveyors, including the frame, drive motor, tensioning device, chains, chain sprockets, sensors, and more.</li>

<li>Bidirectional Operation: The chain conveyor operates in two directions, making it suitable for loading and unloading long workpieces.</li>

<li>Workpiece Movement: Workpieces can be moved out of the cutting line and buffered for efficient handling.</li>

<li>Partitioned Work Areas: The chain is divided into multiple work areas by partition plates, with each area measuring 560mm in width, ideal for the maximum flat steel width of 500mm.<br>

</li>

<li><strong>Vertical Axis "Z"</strong></li>

<li><strong>Vertical Movement of the Laser Head</strong>: The Z-axis is responsible for the vertical movement of the laser head. This motion is controlled by a servo motor through the numerical control system. The motor drives a lead screw, which moves the Z-axis slide plate up and down. Proximity switches at both the upper and lower ends control the stroke, ensuring safe and reliable motion. The lead screw, sourced from a reputable brand, offers high precision, stability, and reliability.</li>

<li><strong>Independent and Synchronized Motion</strong>: The Z-axis can operate as a standalone numerical control axis, performing interpolated motion independently. It can also synchronize with the X and Y axes and switch to follow-up control mode to meet various cutting needs. The follow-up control is managed by the numerical control system, ensuring high precision and stability for consistent cutting quality.</li>

<li><strong>Capacitive Sensor</strong>: The Z-axis mechanism includes a capacitive sensor that detects the distance between the nozzle and the material surface. This feedback is sent to the control system, which adjusts the cutting head's position by controlling the Z-axis motor, maintaining a constant nozzle-to-material distance. This ensures quality cutting throughout the process.</li>

<li><strong>Automatic and Manual Focus Adjustment</strong>: The cutting head can automatically or manually adjust its focal length, allowing for precise control based on the material type and workpiece thickness. This flexibility ensures clean, accurate cuts across a wide range of materials. </li>

<li><strong>Cutting Head (Raytools-SWITZERLAND)</strong></li>

<li>Bevel Cutting Laser Head: The cutting head is standardly equipped with a bevel cutting laser head, offering high-speed servo collimation and zooming capabilities for precise and efficient cuts.</li>

<li>Advanced Monitoring Features: It includes optical temperature monitoring, gas leak detection, and protective window installation monitoring to ensure safe and optimal operation.</li>

<li>Sealed Internal Structure: The cutting head is designed for medium-power, large-format fiber laser cutting applications. Its fully sealed internal structure prevents dust from contaminating optical components, ensuring consistent performance.</li>

<li>Two-Point Centering Adjustment: The laser head features a two-point centering adjustment with manual drive focus adjustment, significantly improving perforation efficiency, especially for cutting small holes.</li>

<li>Easy Lens Replacement: The protective lens is installed in a drawer-type system for easy replacement, ensuring quick maintenance. The cutting head is compatible with various lasers featuring QBH and QD connectors.</li>

<li>Vibration Suppression: Minimizes vibrations to ensure smooth and precise cutting.</li>

<li>Edge Following: Automatically adjusts to follow the edges of the material for accurate cuts.</li>

<li>Smart Collision Avoidance: Detects potential collisions and adjusts the cutting path to prevent damage.</li>

<li>Flash Piercing: Enables faster and more efficient piercing, enhancing the cutting process<br>

</li>

<li><strong>Laser Generator - Fritz FR Pro 12000W Series (GERMANY)</strong></li>

<li>Optimized for Carbon Steel Cutting: Independently developed and specifically optimized for efficient carbon steel cutting.</li>

<li>High Power and Quality Output: Delivers high power and high-quality laser output for precise cutting.</li>

<li>High Electro-Optic Conversion Efficiency: Features a flat distribution of spot energy and high energy density for improved cutting performance.</li>

<li>Compact Structure: Designed with a compact structure and smaller volume, making it space efficient.</li>

<li>Single Module Integration: Built with a high-power single module for a smaller overall size, ensuring excellent performance in a compact package.</li>

<li>Low Processing Cost: Provides excellent performance with reduced processing costs, making it economical for large-scale production.</li>

<li>Modular Design: The modular design allows for easy maintenance and serviceability, ensuring long-term reliability.</li>

<li>Performance Specifications<br>

• Laser Power: 12,000W<br>

• Maximum Cutting Thickness:

<ul>

<li> Carbon Steel: 5/8”</li>

<li>Stainless Steel: 1/2”<br>

</li>

<li>Aluminum: 1/2”</li>

<li>Copper: 1/2”<br>

</li>

</ul>

</li>

<li><strong>CNC Control System (Higerman-GERMANY)</strong>

<ul type="disc">

<li><strong>Automatic Centering:</strong> The system can automatically locate the center during processing, collecting Z-axis information in real-time to achieve high-precision machining.</li>

<li><strong>High-Accuracy Pipe Material Recognition:</strong> It recognizes and processes pipe materials with high accuracy, simplifying the cutting process and improving overall efficiency.</li>

<li><strong>Zero-Waste Processing:</strong> Supports control of 3 chucks (optional), enabling zero-waste processing and helping to reduce raw material costs.</li>

<li><strong>Three-Dimensional Cutting Simulation:</strong> The system allows for three-dimensional cutting simulation on a computer, replicating the real laser cutting process and enhancing processing efficiency.</li>

<li><strong>Software</strong><br>

We are developing the software in collaboration with a Japanese expert, <strong>SPAE</strong>, specifically tailored for steel production to optimize efficiency and precision.</li>

</ul>

</li>

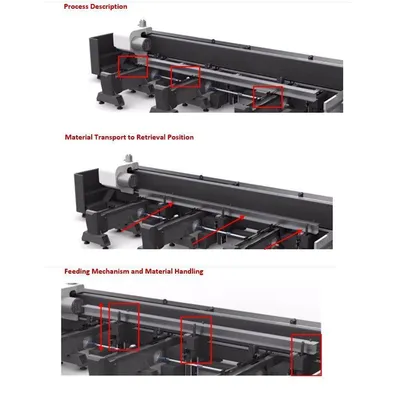

<li><strong>Process Description</strong>

<ul type="disc">

<li>The operator places the workpiece to be processed between two pusher blocks on the material arrangement rack (material area). The workpiece rests against the front side of the pusher block, which is furthest from the machine bed, serving as the workpiece positioning surface for retrieval.</li>

<li>The pusher blocks are mounted on a chain and move along with it. Multiple pusher blocks are installed at equal intervals on the chain. The workpiece is driven by the chain, which is a double-sided bent plate chain.</li>

<li>The spacing between the pusher blocks can be adjusted according to customer requirements, providing flexibility for various workpiece sizes.</li>

<li>The material arrangement rack can hold up to three workpieces, each with dimensions of 550 x 550 mm, at a time.</li>

</ul>

</li>

<li><strong>Material Transport to Retrieval Position</strong>

<ul type="disc">

<li>The motor drives the chain, pulling the workpiece to a specific position in sequence.</li>

<li>The position is determined by detecting the pusher block and checking whether a workpiece is present at that location.</li>

<li>Once both the pusher block and the material are detected, the system waits for the feeding instruction to proceed.</li>

</ul>

</li>

<li><strong>Feeding Mechanism and Material Handling</strong>

<ul type="disc">

<li>The servo follower mechanism, mounted on the feeding mechanism, lifts once it receives the feeding instruction.</li>

<li>The clamping jaw of the servo follower mechanism clamps the workpiece. The jaw transitions from open to closed, lifting the workpiece and detaching it from the plane of the material rack. Each set of follower mechanisms has a lifting capacity of 180 kg and can support workpieces with a side length of up to 550 mm.</li>

<li>The feeding cylinder then transports the material to the centerline of the chuck.</li>

<li>The follower mechanism moves along the Z-axis to deliver the material to the chuck axis.</li>

</ul>

</li>

<li><strong>Workpiece Clamping and Loading Process</strong>

<ul type="disc">

<li>The rear chuck detects the tail end of the material and moves to clamp the workpiece. Based on the pre-input workpiece dimensions, the rear chuck quickly moves to a position near the tail end, then reduces its speed as it approaches. It detects the cross-section of the workpiece, moves forward, and securely clamps it.</li>

<li>The rear chuck then clamps the workpiece and drives it forward until the other end enters the middle chuck, which securely clamps it, completing the loading process.</li>

<li>Processing begins according to the instructions after nesting. During processing, the servo follower mechanism is driven by a servo motor to closely follow the lower contour of the rotating workpiece.</li>

<li>The follower mechanism descends and retracts to the retrieval position in sequence based on the chuck's operating position in the 12-meter direction. As the workpiece moves forward, the follower mechanism continues descending in sequence, adjusting to the real-time position of the rear chuck and waiting for the next lifting instruction. </li>

</ul>

</li>

</ul>