<p><b>SPECIFICATIONS:</b></p>

<table cellspacing="0" cellpadding="0" border="1" width="520">

<tbody style="text-align: center;">

<tr>

<td valign="middle" bgcolor="#333333" class="Title_white_bold"><div align="center"><span style="color: rgb(255, 255, 255);"><b>MODEL</b></span></div></td>

<td width="257" valign="middle" bgcolor="#333333" class="TableText"><div align="center" class="Title_white_bold">

<div align="center"><span style="color: rgb(255, 255, 255);"><b>GAL 1616

</b></span></div>

</div></td>

</tr>

<tr>

<td width="257" valign="middle" bgcolor="#cccccc" class="TableText"><div align="center">Min. Angle Size</div></td>

<td valign="middle" class="TableText"><div align="center">1.50" x 1.50" x 1/8"</div></td>

</tr>

<tr>

<td valign="middle" bgcolor="#cccccc" class="TableText"><div align="center">Max. Angle Size</div></td>

<td valign="middle" class="TableText"><div align="center">6" x 6" x 5/8"</div></td>

</tr>

<tr>

<td valign="middle" bgcolor="#cccccc" class="TableText"><div align="center">Max. length of Finished Angle</div></td>

<td valign="middle" class="TableText"><div align="center">40 ft</div></td>

</tr>

<tr>

<td valign="middle" bgcolor="#cccccc" class="TableText"><div align="center">Punches per Side</div></td>

<td valign="middle" class="TableText"><div align="center">3</div></td>

</tr>

<tr>

<td valign="middle" bgcolor="#cccccc" class="TableText"><div align="center">Max. Punch</div></td>

<td valign="middle" class="TableText"><div align="center">1 in.</div></td>

</tr>

<tr>

<td valign="middle" bgcolor="#cccccc" class="TableText"><div align="center">Max. Punch Tonnage</div></td>

<td valign="middle" class="TableText"><div align="center">105 Tons</div></td>

</tr>

<tr>

<td valign="middle" bgcolor="#cccccc" class="TableText"><div align="center">Max. Shear Tonnage (3 speed)</div></td>

<td valign="middle" class="TableText"><div align="center">330 Tons</div></td>

</tr>

<tr>

<td valign="middle" bgcolor="#cccccc" class="TableText"><div align="center">Max. Marking Tonnage</div></td>

<td valign="middle" class="TableText"><div align="center">130 Ton</div></td>

</tr>

<tr>

<td valign="middle" bgcolor="#cccccc" class="TableText"><div align="center">Shear cycle time</div></td>

<td valign="middle" class="TableText"><div align="center">5 sec.</div></td>

</tr>

<tr>

<td valign="middle" bgcolor="#cccccc" class="TableText"><div align="center">Shearing blade type</div></td>

<td valign="middle" class="TableText"><div align="center">Single</div></td>

</tr>

<tr>

<td valign="middle" bgcolor="#cccccc" class="TableText"><div align="center">Total Power</div></td>

<td valign="middle" class="TableText"><div align="center">45 HP</div></td>

</tr>

<tr>

<td valign="middle" bgcolor="#cccccc" class="TableText"><div align="center">Max. Feeding Speed</div></td>

<td valign="middle" class="TableText"><div align="center">200 ft per min.</div></td>

</tr>

<tr>

<td valign="middle" bgcolor="#cccccc" class="TableText"><div align="center">Machine Weight</div></td>

<td valign="middle" class="TableText"><div align="center">Approx. 35,000 lbs.</div></td>

</tr>

<tr>

<td valign="middle" bgcolor="#cccccc" class="TableText"><div align="center">Overall Size</div></td>

<td valign="middle" class="TableText"><div align="center">65 x 13 x 7 ft.</div></td>

</tr>

</tbody>

</table>

<p><b>FEATURES:</b></p>

<ul>

<li>Rigid Punching Unit: Closed fuselage design for enhanced rigidity.</li>

<li>Clean Cuts: Single-blade cutting mechanism ensures neat cuts with easy-to-adjust shearing clearance.</li>

<li>Rapid Positioning: Pneumatic clamp for fast movement and positioning of the numerical control feeding trolley.</li>

<li>High Accuracy: Servo motor-driven workpiece with rack and pinion and linear guide system for high positioning accuracy (max speed of 260ft/min).</li>

<li>Safety: Collision protection device ensures equipment and personnel safety.</li>

<li>CNC Axis: Controls the movement and positioning of the feeding car.</li>

<li>Stable Hydraulic System: Ferrule structure in the hydraulic pipeline reduces oil leakage and improves equipment stability.</li>

<li>Easy Programming: Computer programming with visual display of workpiece figure, hole positions, and coordinate sizes. Convenient for program storage, recall, fault diagnosis, and computer communication.</li>

<li>These features combine to deliver exceptional precision, efficiency, and durability for your fabrication needs.</li>

<li><strong>TRIPLE TOOL PUNCH PRESS – GATOR GAL 1616

</strong>

<ul>

<li>The Gator GAL 1616 features two 105-ton punch cylinders, each equipped with two punch stations per hydraulic press. This design enables the machine to apply up to two different hole shapes and sizes per leg in a single pass. With its CNC-controlled precision, the GAL 1616 can accommodate a variety of shaped holes, including squares, rectangles, obrounds, and slots, offering versatile solutions for your fabrication needs.</li>

</ul>

</li>

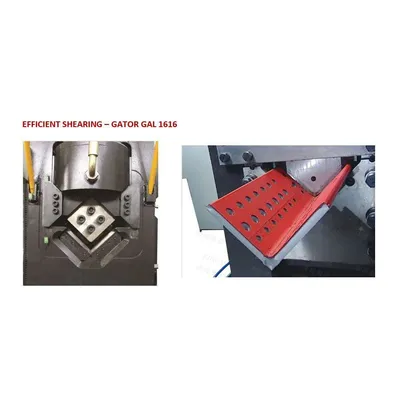

<li><strong>EFFICIENT SHEARING – GATOR GAL 1616

</strong>

<ul>

<li>The GAL 1616 is equipped with a 330-ton single-cut shear press, designed to quickly and accurately cut angle and flat stock to length. Unlike traditional double-cut shear mechanisms, the single-cut system eliminates the creation of slugs, ensuring cleaner cuts and maximizing material efficiency. This advanced shearing technology provides precise, high-performance results with every operation.<br>

</li>

</ul>

</li>

<li><strong>MARKING UNIT

</strong>

<ul>

<li>The marking unit features a closed-frame design for enhanced rigidity. It is equipped with four sets of character boxes, which can be selected via the program. The marking parameters, including stadia, can be easily adjusted as needed.</li>

</ul>

</li>

<li><strong>CONTINUOUS EFFIENCY WITH PUSHING ARM TECHNOLOGY

</strong>

<ul>

<li>Equipped with the Peddinghaus Pushing Arm measurement system, the GAL 1616 maintains constant contact with the material at all times. This Pushing Arm technology ensures consistent movement and precise measurements, even with variations in material.</li>

</ul>

</li>

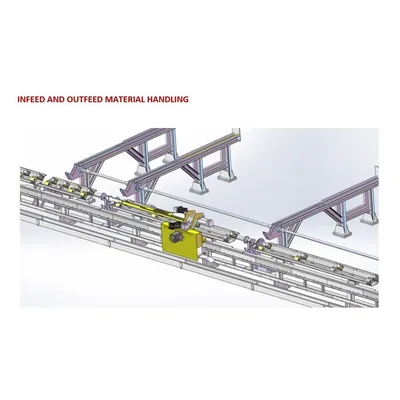

<li><strong>INFEED AND OUTFEED MATERIAL HANDLING

</strong>

<ul>

<li>The infeed and outfeed material handling system, designed for continuous production, ensures operator safety at all times. As drag chain conveyors move material to the infeed section, the powered material advance feeds steel into the machine. After shearing, a pushing arm system moves the finished parts to the unloading zone.</li>

</ul>

</li>

<li><strong>SINGLE CUT SHEAR

</strong>

<ul>

<li>The single-blade shearing system ensures a precise cut every time. The shear clearance is easily adjustable for optimal performance. Unlike double-blade shearing, single cut shearing eliminates the creation of shear slugs, resulting in cleaner cuts and less material waste.<br>

</li>

</ul>

</li>

</ul>