<ul>

<li>The machine body is manufactured using advanced technology with high precision tolerances and stress relief has been applied to large welded components. All stress points are designed with wide radii to eliminate stress concentrations and potential weld cracks.</li>

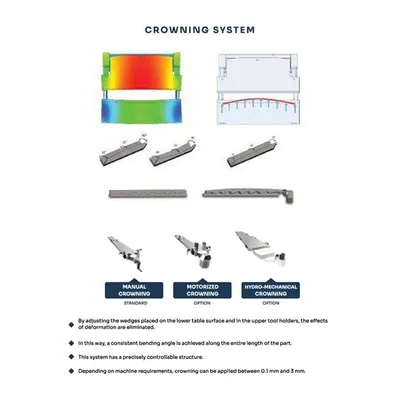

<li>The lower and upper tables are designed with optimized inertia values to minimize deflection.</li>

<li>The upper beam is positioned vertically and the cylinder bearings, piston guides and seals are designed to compensate for vertical loads.</li>

<li>The hydraulic cylinder is designed as double-acting and honed to a 2-micron surface finish, ensuring minimal friction and wear on the seals.</li>

<li>The hydraulic cylinders are mounted to tAhe front of the machine frame using bolts and wedges, providing excellent alignment and load balancing.</li>

<li>The pistons are precision-ground and hard chrome plated to ensure low friction and wear resistance as they pass through the seals.</li>

<li>The adjustable upper beam slideways are made of low-friction material. These guides are designed to ensure precise movement of the upper beam from side to side and front to back.</li>

<li>The hydraulic system allows precise operation at all pressure levels up to the maximum working pressure. These pressure values enable accurate cylinder positioning, synchronization and repeatability.</li>

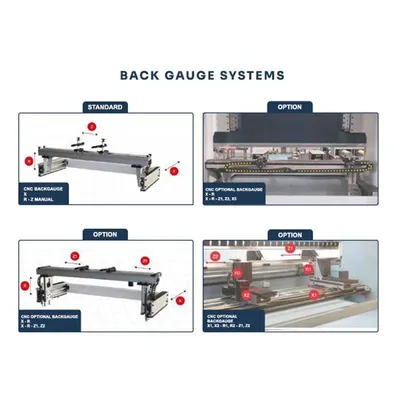

<li>The backgauge system is manufactured to withstand environmental conditions. The backgauge guides are built with dual carriers to perform reliably under heavy-duty conditions.</li>

<li><strong>BACK GAUGE SYSTEMS:</strong>

<ul>

<li>One of the most critical elements that determines the quality of bending is the design and durability of the back gauge. A flawless bend and therefore a flawless product is only possible with a stable and precise back gauge system.</li>

<li>The high-speed back gauge, which works with ballscrew shafts, offers a long-lasting and impact-resistant structure thanks to the double linear guideway support. The stepped back gauge tongue is designed to provide maximum stability and adapt to all you bending needs.</li>

</ul>

</li>

</ul>

<p><b> STANDARD EQUIPMENT:</b></p>

<ul>

<li>Y1,Y2,X, R, Z1 and Z2 – 6-Axis </li>

<li>Bending Force: 220 Ton </li>

<li>Bending Length: 161” </li>

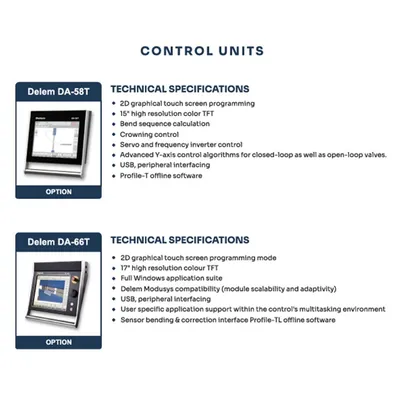

<li>Delem 58T (The Netherlands)</li>

<li>Gator Heavy Type ±0.0012” Accuracy Servo Motor Backgauge</li>

<li>Front Safety Lazer (Fiessler-Germany) </li>

<li>Back Safety Finger Protection System (Fiessler-Germany) </li>

<li>Finger Blocks 2 Pcs </li>

<li>Gator Adjustable Linear Slide Casting Body Front Support Arms 2 Pcs</li>

<li>Gator Special Narrow Table </li>

<li>Gator Bottom Tool Holder (Rolleri-Italy)</li>

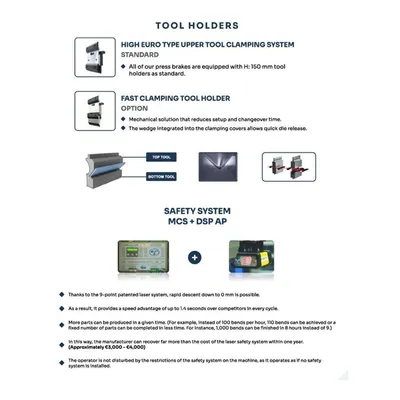

<li>Gator European Type Top Tool Clamping (Promecam-Italy) </li>

<li>European Type Top Tool H: 2.50” 85° R0,8 (Rolleri or Eurostamp-Italy) </li>

<li>European Type Bottom Tool 4V H: 2-3/8” x 2-3/8” 85° (Rolleri or Eurostamp-Italy) </li>

<li>Opkon Magnetic Linear Scale (Turkey)</li>

<li>Electric System (Siemens or Schneider-Germany) </li>

<li>Hydraulic System (Rexroth-Germany) </li>

<li>Hydraulic Pump (Eckerle-Italy) </li>

<li>Servo Driver (Delta or Mitsubishi-Japan) </li>

<li>Electrical Panel - Gator </li>

<li>Lighting Lamp </li>

<li>Gator Foot Pedal with Emergency Stop Button (Stand Type) <br>

</li>

</ul>

<p><b>OPTIONAL ITEMS - CALL FOR PRICE:</b></p>

<ul>

<li>Installation and training</li>

</ul>