<p><b>SPECIFICATIONS:</b></p>

<table>

<tbody>

<tr>

<td width="78" bgcolor="#333333"><span style="color: rgb(255, 255, 255);"><strong>MODEL</strong></span></td>

<td bgcolor="#333333"></td>

<td width="232" bgcolor="#333333"><b><span style="color: rgb(255, 255, 255);">LMV-49-SMD</span></b></td>

</tr>

<tr>

<td width="78" rowspan="9" bgcolor="#333333"><span style="color: rgb(255, 255, 255);"><strong>CAPACITY</strong></span></td>

<td bgcolor="#CCCCCC">Table Size</td>

<td>9 x 49 in. (230 x 1244 mm)</td>

</tr>

<tr>

<td bgcolor="#CCCCCC">T-slots (No., Size, Pitch)</td>

<td>3, 5/8, 2.5 in. (3, 16, 63.5 mm)</td>

</tr>

<tr>

<td bgcolor="#CCCCCC">Table Travel : X Longitudinal</td>

<td>36.6 in. (929mm)</td>

</tr>

<tr>

<td bgcolor="#CCCCCC">Table travel : Y Cross</td>

<td>12 in. (304mm)</td>

</tr>

<tr>

<td bgcolor="#CCCCCC">Quill travel: Z Vertical</td>

<td>5 in. (127mm)</td>

</tr>

<tr>

<td bgcolor="#CCCCCC">Ram Travel</td>

<td>12 in. (304.8mm)</td>

</tr>

<tr>

<td bgcolor="#CCCCCC">Knee travel : Vertical</td>

<td>16 in. (406mm)</td>

</tr>

<tr>

<td bgcolor="#CCCCCC">Spindle Center to Column</td>

<td>6.75 - 18.5 in. (171 - 470 mm)</td>

</tr>

<tr>

<td bgcolor="#CCCCCC">Spindle Nose to Table Top</td>

<td>2.125 - 18 in. (3.1 - 457 mm)</td>

</tr>

<tr>

<td rowspan="8" bgcolor="#333333"> <strong><span style="color: rgb(255, 255, 255);">HEAD, SPINDLE</span></strong></td>

<td bgcolor="#CCCCCC">Spindle Nose Taper</td>

<td>R-8</td>

</tr>

<tr>

<td width="202" bgcolor="#CCCCCC">Spindle Variable Speed Range</td>

<td valign="top">65-4500 rpm</td>

</tr>

<tr>

<td bgcolor="#CCCCCC">Spindle Motor (220V/440V)</td>

<td>11 HP</td>

</tr>

<tr>

<td bgcolor="#CCCCCC">Quill Feed (Inch/Min)(3 speeds)</td>

<td>.0015, .003, .006 in. <br>

(.038, .076, .152 mm)</td>

</tr>

<tr>

<td bgcolor="#CCCCCC">Quill Diameter</td>

<td>3.375 in. (85.7mm)</td>

</tr>

<tr>

<td bgcolor="#CCCCCC">Head Swivel Angle</td>

<td>360°</td>

</tr>

<tr>

<td bgcolor="#CCCCCC">Head Tilt Angle (L/R)</td>

<td>45°</td>

</tr>

<tr>

<td bgcolor="#CCCCCC">Head Tilt Angle (Up/Down)</td>

<td>45°</td>

</tr>

<tr>

<td rowspan="5" bgcolor="#333333"><span style="color: rgb(255, 255, 255);"><strong>GENERAL</strong></span></td>

<td bgcolor="#CCCCCC">Floor Area (W x D x H)</td>

<td>7 x 6.5 x 6.75 ft.</td>

</tr>

<tr>

<td bgcolor="#CCCCCC">Approximate Weight</td>

<td>2,100 lbs.</td>

</tr>

<tr>

<td bgcolor="#CCCCCC">Power Consumption (220V)</td>

<td>3 KVA/15 amps</td>

</tr>

<tr>

<td bgcolor="#CCCCCC">Power Consumption (440V)</td>

<td>3 KVA/8 amps</td>

</tr>

<tr>

<td bgcolor="#CCCCCC">Single Phase</td>

<td>3KVA/25amps</td>

</tr>

</tbody>

</table>

<p><b>FEATURES:</b></p>

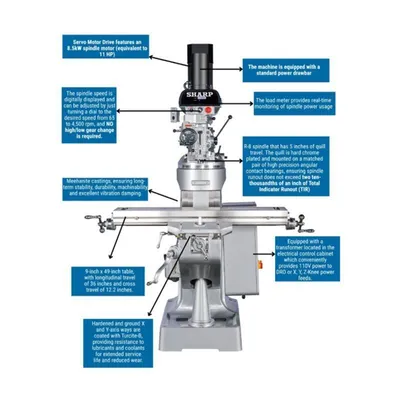

<ul>

<li>The NEW SHARP LMV-49-SMD is a newly designed knee-type vertical milling machine that integrates a Servo Motor Drive with many outstanding and unique features, making it the best choice on the market. With s<span data-olk-copy-source="MessageBody">pindle driven by Servo motor, eliminating high low transmission gears and manual break.</span></li>

<li>The R-8 spindle is driven by a servo motor, providing a speed range of 65 to 4,500 rpm.</li>

<li>An 8.5kW spindle motor that is equivalent to an 11HP drive, which will increase productivity via larger depths of cuts in milling, drilling, boring, and tapping applications.</li>

<li>Fewer working parts to maintain by eliminating High/Low transmission gears and manual break, so the mill is easier to operate, and extends the life of the machine.</li>

<li>Adjusts the speed and torque dynamically, allowing it to run quieter and with less vibration than traditional variable speed drive mills for improved surface finish and extended tool life.</li>

<li>Comes with a digital display, and the speed change is controlled by turning a dial to the desired speed.</li>

<li>Comes standard with a load meter, which provides real-time monitoring of spindle power usage, offering several benefits like preventing tool breakage, improving cutting conditions, and optimizing machine performance.</li>

<li>High Performance in Intermittent Use – Servo motors are ideal for applications with start-stop operations. They can ramp up and down quickly without consuming excessive energy.</li>

<li>Low Energy Loss – Servo motors are designed to minimize energy loss due to heat and friction, contributing to their overall efficiency.</li>

<li>The mill comes equipped with a transformer located in the electrical control cabinet which conveniently provides 110V power to DRO or X, Y, Z-Knee power feeds.</li>

<li>Table size: 9" x 49"</li>

<li>Travel: 36" longitudinal, 12.2" crossTable Size 9" x 49"</li>

<li>Table Travel 36" X-Axis and 12.2 Y-Axis</li>

<li>Power Draw Bar</li>

<li>Meehanite Casting</li>

<li>Front and Rear Way Covers</li>

<li>One Shot Lubrication System</li>

<li><strong>Servo Motor Drive:</strong>

<ul>

<li><span data-olk-copy-source="MessageBody">Spindle driven by Servo motor, eliminating high low transmission gears and manual break.</span></li>

<li>High Performance in Intermittent Use – Servo motors are ideal for applications with start-stop operations. They can ramp up and down quickly without consuming excessive energy.</li>

<li>Low Energy Loss – Servo motors are designed to minimize energy loss due to heat and friction, contributing to their overall efficiency.</li>

<li>The Servo Motor Drive features an 8.5kW spindle motor (equivalent to 11 HP), delivering increased productivity through the ability to take larger depths of cut in milling, drilling, boring, and tapping applications.</li>

<li>The Servo Motor Drive eliminates high- and low-speed transmission changes, reducing wear on parts in the head of the machine and making the mill easier to operate.</li>

<li>The Servo Motors Drive adjusts the speed and torque dynamically, allowing it to run quieter and with less vibration than traditional variable speed drive mills for improved surface finish and extended tool life.</li>

</ul>

</li>

<li><strong>PRECISION QUILL:</strong>

<ul>

<li>The machine is equipped with an R-8 spindle that has 5 inches of quill travel.</li>

<li>The Quill is hard chrome-plated and mounted on a matched pair of high precision angular contact bearings, ensuring spindle runout does not exceed two ten-thousandths of an inch of Total Indicator Runout (TIR).</li>

</ul>

</li>

<li><strong>SPINDLE SPEED AND LOAD DISPLAY

</strong>

<ul>

<li>The spindle speed has a digital display, so the speed change is controlled by just turning a dial to the desired speed, and the load meter provides real-time monitoring of spindle power usage, offering several benefits like preventing tool breakage, improving cutting conditions, and optimizing machine performance.</li>

</ul>

</li>

<li><strong>Power Draw Bar

</strong>

<ul>

<li>The machine is equipped with a standard power drawbar, allowing for quick and effortless tool changes.</li>

</ul>

</li>

<li><strong>HIGH QUALITY CAST IRON

</strong>

<ul>

<li>The structural components of the machine are made from Meehanite castings, ensuring long-term stability, durability, machinability, and excellent vibration damping.</li>

</ul>

</li>

<li><strong>HARDENED AND GROUND SLIDEWAYS

</strong>

<ul>

<li>The hardened and ground X and Y-axis ways are coated with Turcite-B, providing resistance to lubricants and coolants for extended service life and reduced wear.</li>

</ul>

</li>

<li><strong>NO END PLAY OR LATERAL MOVEMENT OF THE TABLE

</strong>

<ul>

<li>Precision thrust bearings mounted at the table end eliminate end play, resulting in smoother motion and improved travel accuracy.</li>

</ul>

</li>

<li><strong>BACKLASH ELIMINATION

</strong>

<ul>

<li>Backlash is eliminated through Sharp’s double-nut design, which maintains full contact between a pair of bronze nuts and the precision-ground leadscrew, ensuring smooth table travel and improved accuracy.</li>

</ul>

</li>

<li><strong>WAY COVERS

</strong>

<ul>

<li>Durable front and rear rubber way covers provide reliable protection against chips, coolant, and contamination, ensuring long machine life.</li>

</ul>

</li>

<li><strong>HEAD SWIVELING AND TILTING

</strong>

<ul>

<li>Enhanced flexibility, the milling head swivels a full 360°, tilts 90° to the right or left, and angles 25° upward or 45° downward to accommodate a wide range of angular machining operations.</li>

</ul>

</li>

<li><strong>PATENTED KNUCKLED HEAD DESIGN

</strong>

<ul>

<li>The exclusively designed knuckled head uses six bolts and is fitted into the circular T-slots to prevent the head from slipping.</li>

</ul>

</li>

<li><strong>ELECTRICAL CONTROL CABINET

</strong>

<ul>

<li>The mill comes equipped with a transformer located in the electrical control cabinet which conveniently provides 110V power to DRO or X, Y, Z-Knee power feeds.</li>

</ul>

</li>

<li><strong>ONE SHOT LUBRICATION SYSTEM

</strong>

<ul>

<li>The One-Shot Lubrication System, equipped with a backflow valve, ensures consistent lubrication of all ways and lead screws on the X, Y, and Z axes.</li>

</ul>

</li>

</ul>