<p><b>SPECIFICATIONS:</b></p>

<table cellspacing="0" cellpadding="0" border="1" width="520">

<tbody style="text-align: center;">

<tr>

<td width="257" valign="middle" bgcolor="#333333" class="Title_white_bold"><div align="center"><span style="color: rgb(255, 255, 255);"><b>MODEL</b></span></div></td>

<td width="257" valign="middle" bgcolor="#333333" class="TableText"><div align="center"><span style="color: rgb(255, 255, 255);"><b><span class="Title_white_bold" style="color: rgb(255, 255, 255);">GBS12 3015-L12</span></b></span></div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">Max Working Area</div></td>

<td valign="middle" class="TableText"><div align="center">60 x 120 in.</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" width="257" valign="middle" class="TableText"><div align="center">X-axis Stroke</div></td>

<td valign="middle" class="TableText"><div align="center">60 in.</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">Y-axis Stroke</div></td>

<td valign="middle" class="TableText"><div align="center">120 in.</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">Z-axis Stroke</div></td>

<td valign="middle" class="TableText"><div align="center">5.1 in.</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">X/Y Positioning Accuracy </div></td>

<td valign="middle" class="TableText"><div align="center">± .001 in.</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">X/Y Reposition Accuracy </div></td>

<td valign="middle" class="TableText"><div align="center">± .002 in.</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">X/Y Max Moving Speed</div></td>

<td valign="middle" class="TableText"><div align="center">472 ft/min</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">Max. Acceleration</div></td>

<td valign="middle" class="TableText"><div align="center">2.5G</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">Exchanging time of the 2-working table/pallets</div></td>

<td valign="middle" class="TableText"><div align="center">Within 45 sec</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">Transmission</div></td>

<td valign="middle" class="TableText"><div align="center">Precision dual -gear rack drive</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">Max. Loading Capacity</div></td>

<td valign="middle" class="TableText"><div align="center">8,900 lbs.</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">Specified voltage and frequency</div></td>

<td valign="middle" class="TableText"><div align="center">480v/3ph/60HZ</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">Available Laser Source</div></td>

<td valign="middle" class="TableText"><div align="center">12,000W</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">Overall Dimension (LxWxH)</div></td>

<td valign="middle" class="TableText"><div align="center">30 x 9 x 7 ft</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">Weight</div></td>

<td valign="middle" class="TableText"><div align="center">28,000 lbs.</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">Container</div></td>

<td valign="middle" class="TableText"><div align="center">1*40HQ</div></td>

</tr>

</tbody>

</table>

<p></p>

<p><b>MAIN CONFIGURATION:</b></p>

<table cellspacing="0" cellpadding="0" border="1" width="520">

<tbody style="text-align: center;">

<tr>

<td width="257" valign="middle" bgcolor="#333333" class="Title_white_bold"><div align="center"><span style="color: rgb(255, 255, 255);"><b>MODEL</b></span></div></td>

<td width="257" valign="middle" bgcolor="#333333" class="TableText"><div align="center"><span style="color: rgb(255, 255, 255);"><b><span class="Title_white_bold" style="color: rgb(255, 255, 255);">3015</span></b></span></div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">Power</div></td>

<td valign="middle" class="TableText"><div align="center">12,000W</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" width="257" valign="middle" class="TableText"><div align="center">Laser Source</div></td>

<td valign="middle" class="TableText"><div align="center">MAX Photonics</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">Laser Head</div></td>

<td valign="middle" class="TableText"><div align="center">Raytools Auto Focus - SWITZERLAND</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">Gear and Rack</div></td>

<td valign="middle" class="TableText"><div align="center">Framo Morat - GERMANY</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">Reducer</div></td>

<td valign="middle" class="TableText"><div align="center">Framo Morat - GERMANY</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">Servo Motor</div></td>

<td valign="middle" class="TableText"><div align="center">Kollmorgen Altra - USA</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">Electronic Components</div></td>

<td valign="middle" class="TableText"><div align="center">Schneider - FRANCE</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">Pneumatic Components</div></td>

<td valign="middle" class="TableText"><div align="center">CKD/SMC - JAPAN</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">Bearing</div></td>

<td valign="middle" class="TableText"><div align="center">NSK - JAPAN</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">Guide Rail</div></td>

<td valign="middle" class="TableText"><div align="center">Bosch Rexroth - GERMANY</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">Controller (can run offline)</div></td>

<td valign="middle" class="TableText"><div align="center">Lynca - SWITZERLAND</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">Software (can run offline)</div></td>

<td valign="middle" class="TableText"><div align="center">Lantek - SPAIN</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">Automatic Rail Lubrication System</div></td>

<td valign="middle" class="TableText"><div align="center">Yes</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">Cooling Type</div></td>

<td valign="middle" class="TableText"><div align="center">Water cooling</div></td>

</tr>

</tbody>

</table>

<p></p>

<p><b>FEATURES:</b></p>

<ul>

<li> <strong>Configuration Details:</strong></li>

<li><strong>MAX LASER SOURCE 12 kW: </strong>The laser features a <strong>water-cooling</strong> system and <strong>shelf-case design</strong>, offering several competitive advantages, including:

<ul>

<li>High electro-optic conversion efficiency</li>

<li>High reliability and long service life</li>

<li>Maintenance-free operation</li>

<li>Low power consumption</li>

<li>Maintenance-free operation</li>

<li>Fiber delivery system</li>

<li>Ease of movement and assembly</li>

</ul>

</li>

<li><strong>Bridge Design and Side Door Features</strong>: During the bridge design process, all analyses are conducted with consideration of various types of deformation to ensure structural integrity. The machine includes a <strong>side door</strong> that can be used in cases where <strong>intervention is needed during cutting</strong>. This side door is also designed for easy access during <strong>machine maintenance</strong>, allowing for efficient servicing and adjustments.</li>

<li><strong>WIFI Remote Control System: </strong>This function allows remote control of both your computer and machine via WiFi. It enables us to assist you in <strong>installation</strong>, <strong>operation</strong>, or <strong>troubleshooting</strong> by guiding you through the process in just a few minutes, helping resolve any issues quickly and efficiently.</li>

<li><strong>High axis acceleration:</strong> The system is designed for high axis acceleration and vibration-free movement, ensuring high precision cutting quality, even at very high speeds. The bridge construction is strong and retains its shape under the influence of force or moment, providing exceptional rigidity and stability. This design maintains its form, delivering superior performance during fast, dynamic movements. As a result, it ensures high-quality cuts with excellent precision, making it the <strong>world's most preferred cutting head</strong>.</li>

<li><strong>Gear and Rack - [GERMANY] Bosch Rexroth</strong>: Bosch Rexroth gears and racks are designed for <strong>high precision</strong> and <strong>long service life</strong>, providing reliable support for both <strong>quenching helical gears</strong> and <strong>grinding helical gears</strong>. The result is a <strong>compact load drive structure</strong> that effectively <strong>reduces driving torque</strong>, improving efficiency and performance. These high-quality components ensure smooth operation even under demanding conditions.</li>

<li><strong>Rack and Pinion System (JAPAN):</strong> Axis movements are powered by a rack and pinion system. Since there is no additional drive element between the motor and pinion gear, this setup ensures no deviation in measurements, maintaining high precision and accuracy.

<ul>

<li>Linear Motors:<br>

State-of-the-art linear motors are used for axis <br>

movements, enabling extremely high acceleration and <br>

fast movement speeds. With linear motors, the system <br>

achieves:</li>

<li>• High Acceleration: Up to 115ft/s²<br>

• Fast Movement Speed: Up to 743ft/min<br>

• Precise Positioning: Tolerance of .0011”</li>

</ul>

</li>

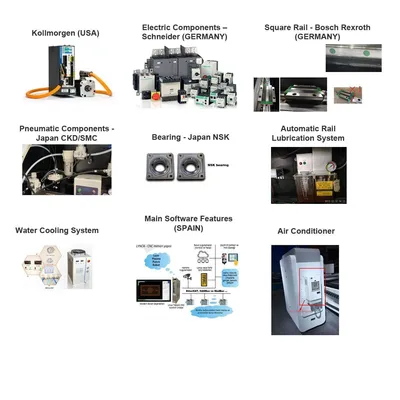

<li><strong>Kollmorgen (USA)</strong> introduces the next generation of motion technology with the Kollmorgen 2G Motion System, designed for the most demanding machines. Built on superior performance and advanced engineering, the AKM2G servo motors and AKD2G drives work together to deliver unmatched power density and exceptional control.<br>

This system offers:

<ul>

<li> Easy Installation: Compact and flexible design that simplifies machine integration.</li>

<li>Improved Torque and Responsiveness: Enhanced performance for more dynamic motion.<br>

</li>

<li>SafeMotion Capabilities: Built-in safety features for greater reliability and protection.</li>

</ul>

</li>

<li>For existing machines, the Kollmorgen 2G Motion System offers a simple, cost-effective upgrade path to boost power and performance. For new designs, it’s a game-changer, enabling the creation of lighter, more compact, and more efficient machines with unprecedented performance.</li>

<li><strong>Electric Components – Schneider (GERMANY)</strong><br>

1. Circuit protection against short-circuit currents, Circuit protection against overload currents, Breaking and industrial disconnection as per standards IEC/EN 60947-2.<br>

2. Overvoltage resistance, High performance limitation to fast closing independent of the speed of actuation of the toggle.</li>

<li><strong>Square Rail - Bosch Rexroth (GERMANY)</strong><br>

Low Noise and Wear-Resistant: Designed for smooth operation, minimizing noise and wear while maintaining a fast moving speed for the laser head.<br>

Optimal Load Distribution: Features 1.38” width rails with four pieces per table to evenly distribute the load and reduce pressure on the rail, ensuring long-lasting performance and stability.</li>

<li><strong>Pneumatic Components - Japan CKD/SMC</strong>

<ul>

<li>Stepless Air Pressure Control: Provides continuous, precise control of air pressure, proportional to the electrical signal.</li>

<li>Serial Communication: Supports serial communication for seamless integration with other systems.</li>

<li>Compact and Lightweight: The components are designed to <br>

be compact and lightweight, with integrated communication parts for efficient space usage and easy installation.</li>

</ul>

</li>

<li><strong>Bearing - Japan NSK

</strong>

<ul>

<li>Square Flange Design: The bearing housings feature a square flange, making them easy to attach to a machine using four bolts.</li>

<li>Versatile and Easy to Mount: With a simple mounting face, this bearing unit is widely used in various applications due to its ease of installation and reliability.</li>

</ul>

</li>

<li><strong>Automatic Rail Lubrication System</strong><br>

The automatic rail lubrication system allows users to set the oiling frequency and quantity through adjustable parameters on the computer. This feature significantly extends the machine's lifespan by ensuring proper lubrication, while also saving manpower and reducing maintenance efforts.</li>

<li><strong>Water Cooling System</strong><br>

The dual cooling function ensures proper temperature control by using hot water to cool the laser head and cool water for the laser source. This system helps maintain both components at optimal temperatures, ensuring their reliable performance and preventing overheating during operation.</li>

<li><strong>Main Software Features (SPAIN)</strong>

<ul>

<li>Sheet Metal Detection: Using a camera to detect sheet metal</li>

<li>Cloud Access: Remote access to machine information via a cloud application</li>

<li>Custom HMI Design: Personalizable HMI interface using web design tools</li>

<li>Customizable Function Buttons: Ability to create and organize function buttons based on their purpose</li>

<li>Tiptouch Return Time and Number: Adjustable return time and count for Tiptouch functionality</li>

<li>Contour Coloring: Ability to color-code contours for easier identification</li>

<li>Micro Joint Insertion via CNC: CNC-controlled insertion of micro joints</li>

<li>Sheet Metal Recognition: Automatic or manual detection of sheet metal</li>

<li>Automatic Sheet Metal Loading: Automated loading of sheet metal onto the machine</li>

<li>Cutting Recipe Creation: Function to create and save cutting recipes</li>

<li>Gas Test: Function for testing the cutting gas</li>

<li>Focus Adjustment: Automatic adjustment of cutting focus</li>

<li>Kerf Calculation: Automatic calculation of kerf (cut width)</li>

<li>Automatic Height Control and Sensor Calibration: Auto-adjustment of cutting height with sensor calibration</li>

<li>Auto-Resume: Automatic continuation of cutting from the last position after a stop</li>

<li>Manual Cutting of Residual Parts: Option to manually cut leftover parts</li>

<li>Work Area Transformation: Ability to adjust or reconfigure the work area</li>

</ul>

</li>

<li><strong>Air Conditioner</strong>: The air conditioner effectively reduces the temperature in the circuit and laser source within the electrical cabinet, ensuring optimal performance during hot summer months. It helps maintain a stable working environment and prevents overheating of critical components.</li>

</ul>

<p><b>OPTIONAL ITEMS - CALL FOR PRICE:</b></p>

<ul>

<li>Air Compressor DBZY20A</li>

<li>Dust Collector (Vacuum Filter) System</li>

<li>27” Camera System: 1920-1080 Full HD</li>

</ul>