<p><b>TECHNICAL PARAMETERS OF 11 AXIS:</b></p>

<table cellspacing="0" cellpadding="0" border="1" width="520">

<tbody style="text-align: center;">

<tr>

<td width="129" rowspan="5" bgcolor="#cccccc" class="TableText"><div align="center"><strong>Combi Upper Beam <br>

(Z axis)</strong></div></td>

<td bgcolor="#cccccc" class="TableText"><div align="center">Opening height <br>

(without tools)</div></td>

<td width="253" class="TableText"><div align="center">9.84 in.</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" class="TableText"><div align="center">Motor Power (Servo)</div></td>

<td class="TableText"><div align="center">2 X 3,5 kW</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" class="TableText"><div align="center">Transmission system</div></td>

<td class="TableText"><div align="center">Ballscrew spindle</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" class="TableText"><div align="center">Clamping speed</div></td>

<td class="TableText"><div align="center">2.55 in.</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" width="130" class="TableText"><div align="center">Combi beam rotation (180°) time</div></td>

<td class="TableText"><div align="center">10 sec</div></td>

</tr>

<tr>

<td rowspan="3" bgcolor="#cccccc" class="TableText"><div align="center"><strong>Folding Beam <br>

(Y axis)</strong></div></td>

<td bgcolor="#cccccc" class="TableText"><div align="center">Folding angle</div></td>

<td class="TableText"><div align="center">0 - 150°</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" class="TableText"><div align="center">Motor Power <br>

(Sew Eurodrive AC)</div></td>

<td class="TableText"><div align="center">2 X 4 kW</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" class="TableText"><div align="center">Folding Speed</div></td>

<td class="TableText"><div align="center">70°/sec</div></td>

</tr>

<tr>

<td rowspan="2" bgcolor="#cccccc" class="TableText"><div align="center"><strong>Folding Beam Height Adjustment <br>

(A1-A2 axis) </strong></div></td>

<td bgcolor="#cccccc" class="TableText"><div align="center">Adjustment height</div></td>

<td class="TableText"><div align="center">0 to 3.14 in.</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" class="TableText"><div align="center">Control</div></td>

<td class="TableText"><div align="center">Manual</div></td>

</tr>

<tr>

<td rowspan="3" bgcolor="#cccccc" class="TableText"><div align="center"><strong>Back gauge system <br>

(X axis)</strong></div></td>

<td bgcolor="#cccccc" class="TableText"><div align="center">Movement speed</div></td>

<td class="TableText"><div align="center">11.81 in. /sec</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" class="TableText"><div align="center">Motor Power (Servo)</div></td>

<td class="TableText"><div align="center">750 W</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" class="TableText"><div align="center">Positioning / repeatability accuracy</div></td>

<td class="TableText"><div align="center">+/- 0,1 mm</div></td>

</tr>

</tbody>

</table>

<p><b>FEATURES:</b></p>

<ul>

<li>Dual drive clamping beam with ball screw spindle system for more clamping power.</li>

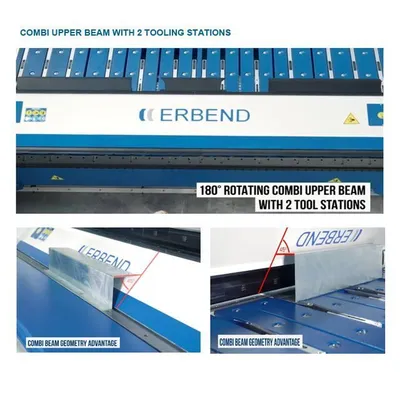

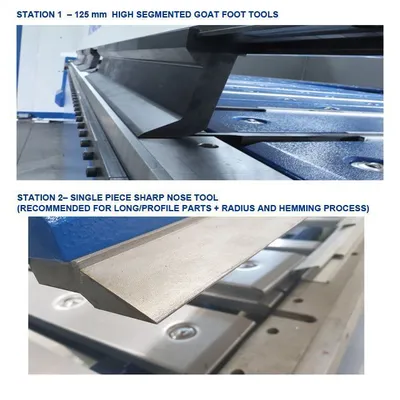

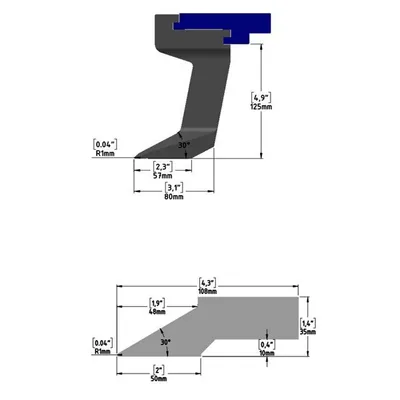

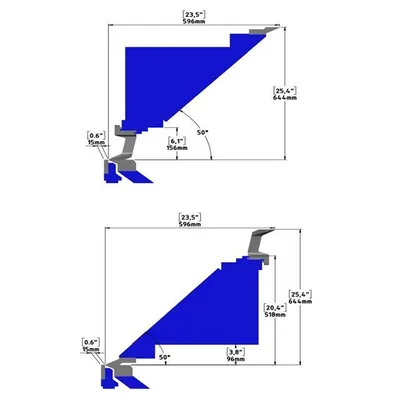

<li>9.84 inch opening height on 180° rotating combi clamping beam with 2 tooling stations as 4.92 inch high segmented goat foot tools on station 1 and 30° single piece sharp nose tool on station 2.</li>

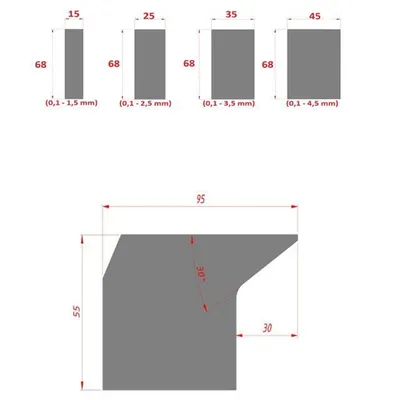

<li>Solid lower beam with channels and 2 sets of single piece folding tools as 0.59 and 1.57 inch wide.</li>

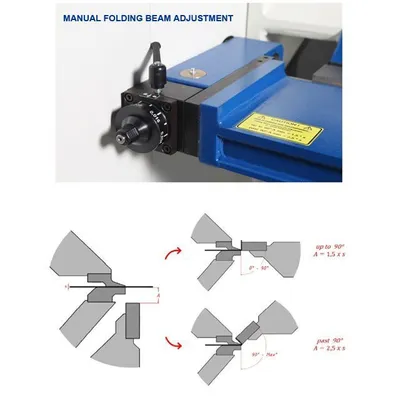

<li>Manual folding beam adjustment.</li>

<li>ERFOLD BASIC CNC LBL control software on 15.6" touchscreen controller with swivel arm.</li>

<li>59 inch servo back gauge system with pneumatic solid fingers and sheet support table with ball casters.</li>

<li>Front light barriers.</li>

</ul>

<p><b> STANDARD EQUIPMENT:</b></p>

<ul>

<li><strong><u>COMBI UPPER BEAM WITH 2 TOOLING STATIONS</u></strong></li>

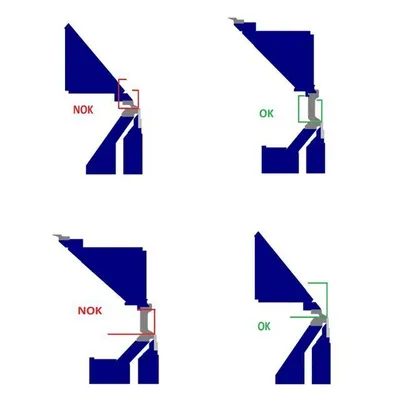

<li>Thanks to 180° rotating 2 station clamping beam, according to your part and programming, the beam can switch to suitable station and make you easily do the deep/box bending or long/profile bendings at the same machine, just in seconds, without changing the tool set-up.</li>

<li>With its 9.84 in. opening height capacity, you can do box/pan bendings up to 4.92 in. depth<strong><u> </u></strong></li>

<li>Thanks to the dual driven ballscrew spindle system, you can use maximum power for clamping, especially effective for hemming operations<strong><u> </u></strong></li>

<li>Thanks to its brass and oil-free friction plates on the linear guides, you can work for years without any lubrication or maintenance<strong><u> </u></strong></li>

<li>Also thanks to the protective bellows, no dirt or dust is allowed in the swivel parts of this axis<strong><u> </u></strong></li>

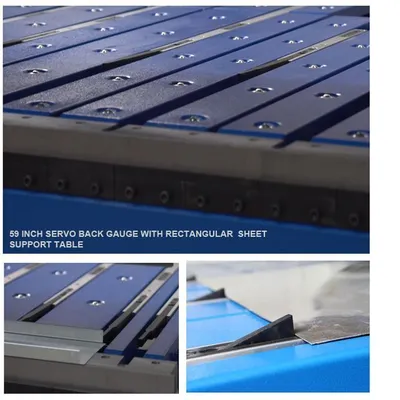

<li><strong><u>59 INCH SERVO BACK GAUGE WITH RECTANGULAR SHEET SUPPORT TABLE</u></strong></li>

<li>59 inch servo driven back gauge system</li>

<li>59 inch long rectangular sheet support table with stainless ball-casters</li>

<li>14 set pneumatic lifted gauging arms with solid fingers + pneumatic triangle fingers as 2 sectors</li>

<li>Sliders can be pulled back to create space for down flanges at the back of the bottom tool</li>

<li><strong><u>FOOT PEDAL WITH 3 SWITCHES</u></strong></li>

<li><strong>3 switch foot pedal with panic button function on two steps.</strong><br>

(Sudden step on left pedal = clamping beam goes up immediately)<br>

(Sudden step on middle pedal = folding beam and all axis stops immediately) </li>

<li><strong><u>VERTICAL OR HORIZONTAL FRONT LIGHT BARRIERS</u></strong></li>

<li>For operator safety, front light barriers are located at the left and right front side of the machine, managed by safety PLC and prevent unwanted interventions to avoid accidents. You can choose as horizontal or vertical or you can completely remove the light barriers from your configuration.</li>

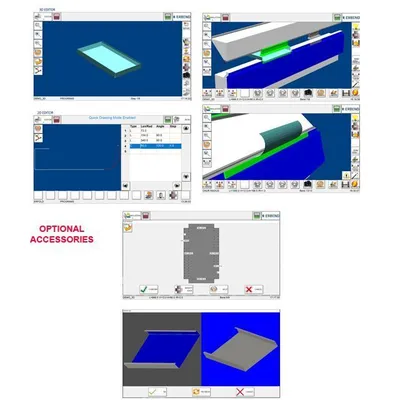

<li><strong><u>ERFOLD BASIC CNC LINE BY LINE CONTROLLER SOFTWARE</u></strong></li>

<li>15.6" touchscreen PC based controller on swivel arm</li>

<li>Line by line part programming by entering numerical values of the axes</li>

<li>Creating,saving,loading parts with different names,materials and sheet thicknesses</li>

<li>Open or drop hemming function</li>

<li>Multi radius bending function</li>

<li>16 GB memory for unlimited receipt storage</li>

<li>Manual axis controls, alarm and error indications, machine detailed parameters</li>

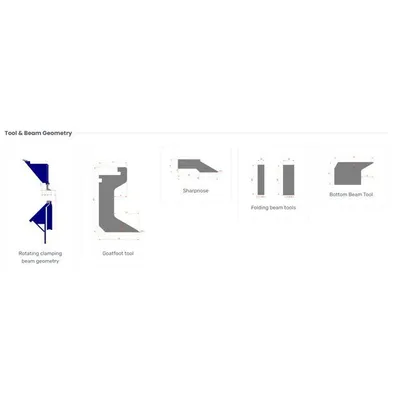

<li><strong>STANDARD TOOLS:</strong></li>

<li><strong><u>STATION 1 – 4.92 inch HIGH SEGMENTED GOAT FOOT TOOLS</u></strong>

<ul>

<li>42CrMo4 grinded material, nose part is 60 RC laser surface hardened and whole body is darkened against corrosion and laser marked regarding the segment length and height</li>

<li>Segmented between 1.18 – 19.68 inch lengths (2 pcs corner tools included)</li>

</ul>

</li>

<li><strong><u>STATION 2– SINGLE PIECE SHARP NOSE TOOL </u></strong><br>

<strong><u>(RECOMMENDED FOR LONG/PROFILE PARTS + RADIUS AND HEMMING PROCESS)</u></strong>

<ul>

<li>Grinded material, single piece, 30° nose angle.</li>

</ul>

</li>

<li><strong><u>MANUAL FOLDING BEAM ADJUSTMENT</u></strong></li>

<li>Manual height adjustment of folding beam up to 3.14 inch according to the sheet thickness or bending point radius requested.</li>

<li>Located in left and right side and should be adjusted equally on both sides</li>

</ul>

<p><b>OPTIONAL ITEMS:</b></p>

<ul>

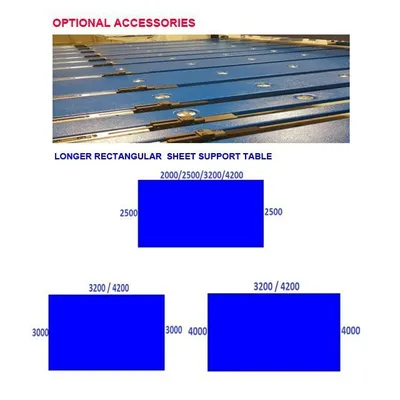

<li>98.4 / 126 / 165.3 inch servo backgauge system upgrade with L / T / U shape sheet support table options.</li>

<li>ERFOLD ADVANCED 2D/3D cnc graphic control software.</li>

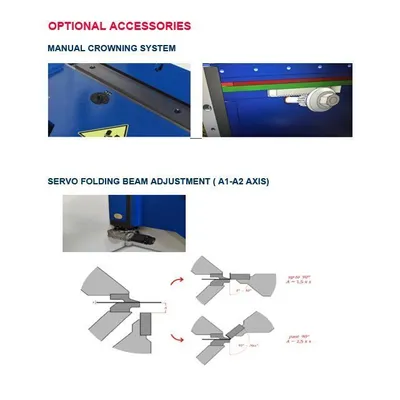

<li>Servo folding beam adjustment.</li>

<li>Manual crowning system.</li>

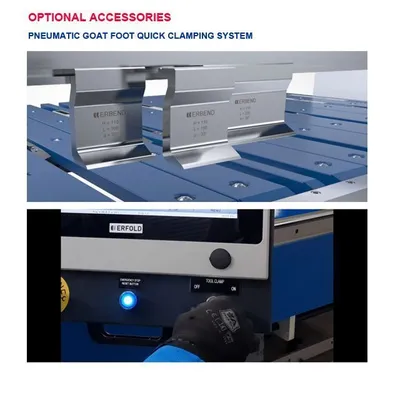

<li>Pneumatic quick goatfoot tool clamping.</li>

<li>Segmented bottom or folding tools.</li>

</ul>