<table>

<tbody>

<tr>

<td></td>

<td>

<b><span style="color: rgb(248, 248, 255);">MODEL</span></b>

</td>

<td>

<b><span style="color: rgb(248, 248, 255);">MP5000XP</span></b>

</td>

</tr>

<tr>

<td rowspan="5" bgcolor="#333333"><span style="color: rgb(248, 248, 255);"><b><div style="text-align: center;">SPEED</div></b></span></td>

<td bgcolor="#cccccc">Strokes per minute</td>

<td>24</td>

</tr>

<tr>

<td bgcolor="#cccccc">Motor</td>

<td>110V AC single phase, <br>

1.5 HP, 2 Stage Pump</td>

</tr>

<tr>

<td bgcolor="#cccccc">Capacity</td>

<td>50 Tons</td>

</tr>

<tr>

<td bgcolor="#cccccc">Throat Depth</td>

<td>3-3/4"</td>

</tr>

<tr>

<td bgcolor="#cccccc">Punch</td>

<td>50 ton max capacity</td>

</tr>

<tr>

<td rowspan="6" bgcolor="#333333"><span style="color: rgb(248, 248, 255);"><b><div style="text-align: center;">SHEAR</div></b></span></td>

<td bgcolor="#cccccc">Flat bar</td>

<td>up to 1/2"</td>

</tr>

<tr>

<td bgcolor="#cccccc">Angle</td>

<td>1/4" x 4" x 4"</td>

</tr>

<tr>

<td bgcolor="#cccccc">Rod</td>

<td>3/4"</td>

</tr>

<tr>

<td bgcolor="#cccccc">Square</td>

<td>5/8"</td>

</tr>

<tr>

<td bgcolor="#cccccc">Hydraulics</td>

<td>2900 PSI</td>

</tr>

<tr>

<td bgcolor="#cccccc">Oil capacity</td>

<td>1.5 US gallons</td>

</tr>

<tr>

<td rowspan="7" bgcolor="#333333"><span style="color: rgb(248, 248, 255);"><b><div style="text-align: center;">ACCESSORIES (Included)</div></b></span></td>

<td bgcolor="#cccccc">Brake</td>

<td>12 inch brake w/ back stop <br>

and front guide table</td>

</tr>

<tr>

<td bgcolor="#cccccc">Limit Switch Kit</td>

<td>stroke control with microadjust</td>

</tr>

<tr>

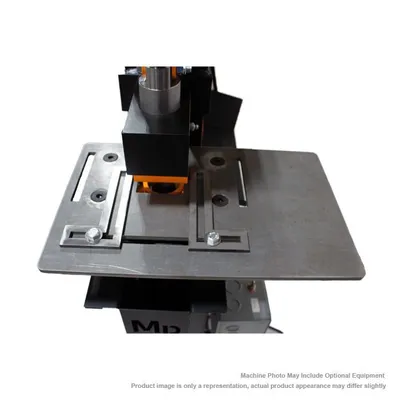

<td bgcolor="#cccccc">Guide Plates</td>

<td>punch station plate and<br>

shear shelf extension</td>

</tr>

<tr>

<td bgcolor="#cccccc">Slug Catcher</td>

<td>holds hundreds of slugs</td>

</tr>

<tr>

<td bgcolor="#cccccc">Wheel kit</td>

<td>locking casters</td>

</tr>

<tr>

<td bgcolor="#cccccc">Shear back stop</td>

<td>adjustable shear back stop for repeat cuts</td>

</tr>

<tr>

<td bgcolor="#cccccc">Punch and die set</td>

<td>8 piece PD set <br>

(standard bolt hole sizes)</td>

</tr>

<tr>

<td width="104" rowspan="4" bgcolor="#333333"><span style="color: rgb(248, 248, 255);"><b><div style="text-align: center;">FRAME DIMENSIONS</div></b></span></td>

<td bgcolor="#cccccc" width="210">Width</td>

<td width="198">24"</td>

</tr>

<tr>

<td bgcolor="#cccccc" width="210">Height</td>

<td>59"</td>

</tr>

<tr>

<td bgcolor="#cccccc" width="210">Length</td>

<td>36-1/2"</td>

</tr>

<tr>

<td bgcolor="#cccccc">Weight</td>

<td>900 lbs.</td>

</tr>

</tbody>

</table>

<ul>

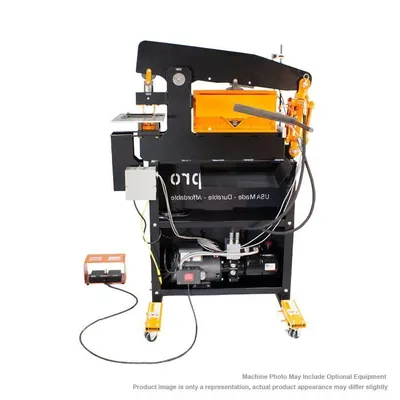

<li>XP = XTRA PRODUCTION</li>

<li>Our XP models are made and designed with production in mind. These models are efficient with an equipped 1.5HP Baldor motor, 2 stage gear pump that produces 26 stokes per minute. This XP model comes standard with a plethora of tooling and accessories designed for high-output production.</li>

<li>We ensure the highest quality standards, souring 100 percent of our components in the<br>

USA. Quality you can trust, and backed industry leading 3 year warranty.</li>

<li>You can find our METALpro Ironworkers with one of our 100+ distributors across the US. With 30 years of dedicated service to this industry we have developed a strong dealer network dedicated to taking care of our customers! Choose METALpro!</li>

<li>APPLICATIONS - All in one ‘fabrication shop’ with capabilities in:

<ul>

<li>Punching</li>

<li>Forming</li>

<li>Shearing</li>

<li>Pressing</li>

<li>Notching</li>

<li>Pipe notching</li>

<li>Bending</li>

</ul>

</li>

<li>*Rated on 65,000 PSI Tensile</li>

<li>**NOTCHERS AND OTHER CUSTOM TOOLING SOLD SEPERATELY</li>

<li>Made in the USA</li>

</ul>

<p><b> STANDARD FEATURES:</b></p>

<ul>

<li>HI-LO 2 stage gear pump, 1.5HP Baldor Motor</li>

<li>Punch capacity of 45 tons</li>

<li>Power cavity with 3-in-1 8 inch shear<br>

</li>

<li>12 inch brake with back stop and guide table</li>

<li>8 piece punch and die set (standard bolt hole sizes)</li>

<li>Wheel kit for maneuverability</li>

<li>Stroke control kit with microadjust</li>

<li>Punch and shear station guide tables</li>

<li>Built in slug catcher</li>

<li>Guarding complies with ANSI B11-8 standards</li>

<li>3 year warranty</li>

</ul>