<table cellspacing="0" cellpadding="0" border="1" width="520">

<tbody style="text-align: center;">

<tr>

<td width="149" rowspan="2" valign="middle" bgcolor="#333333" class="Title_white_bold"><div align="center"><span style="color: rgb(255, 255, 255);"><b>CAPACITY TABLE</b></span></div></td>

<td colspan="3" valign="middle" bgcolor="#333333" class="Title_white_bold"><div align="center"><span style="color: rgb(255, 255, 255);"><b>GAR 100</b></span></div></td>

</tr>

<tr>

<td width="179" valign="middle" bgcolor="#333333" class="TableText"><div align="center"><span style="color: rgb(255, 255, 255);"><b><span class="Title_white_bold">SECTION SIZE (in.)</span></b></span></div></td>

<td width="80" valign="middle" bgcolor="#333333" class="TableText"><div align="center"><span style="color: rgb(255, 255, 255);"><b><span class="Title_white_bold">Min. Diameter (in.)</span></b></span></div></td>

<td width="102" valign="middle" bgcolor="#333333" class="TableText"><div align="center"><span style="color: rgb(255, 255, 255);"><b><span class="Title_white_bold" style="color: rgb(255, 255, 255);">Rolls</span></b></span></div></td>

</tr>

<tr>

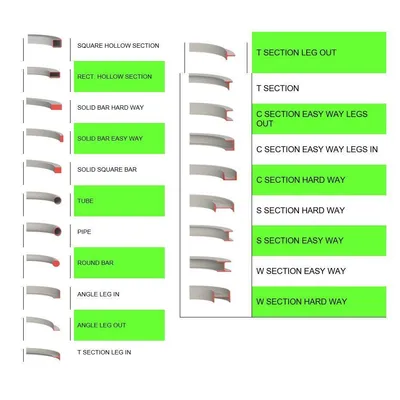

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">SQUARE HOLLOW SECTION</div></td>

<td valign="middle" class="TableText"><div align="center">HSS 2x2x.125<br>

HSS 3-1/2x3-1/2x.125<br>

HSS 4x4x.188</div></td>

<td valign="middle" class="TableText"><div align="center">21<br>

90<br>

106</div></td>

<td valign="middle" class="TableText"><div align="center">STANDARD + P</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">RECT. HOLLOW SECTION</div></td>

<td valign="middle" class="TableText"><div align="center">HSS 2x1x.125<br>

HSS 3x1-1/2x.125<br>

HSS 4x2x.188</div></td>

<td valign="middle" class="TableText"><div align="center">18<br>

32<br>

79</div></td>

<td valign="middle" class="TableText"><div align="center">STANDARD + P</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">SOLID BAR HARD WAY</div></td>

<td valign="middle" class="TableText"><div align="center">1.97x.4<br>

3.15x1<br>

4.7x1.18</div></td>

<td valign="middle" class="TableText"><div align="center">16<br>

20<br>

79</div></td>

<td valign="middle" class="TableText"><div align="center">STANDARD</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">SOLID BAR EASY WAY</div></td>

<td valign="middle" class="TableText"><div align="center">2.57x.4<br>

14.7x1<br>

7x1.57</div></td>

<td valign="middle" class="TableText"><div align="center">16<br>

22<br>

36</div></td>

<td valign="middle" class="TableText"><div align="center">STANDARD</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">SOLID SQUARE BAR</div></td>

<td valign="middle" class="TableText"><div align="center">.79x.79<br>

1.57x1.57<br>

2.36x2.36</div></td>

<td valign="middle" class="TableText"><div align="center">16<br>

22<br>

36</div></td>

<td valign="middle" class="TableText"><div align="center">STANDARD</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">TUBE</div></td>

<td valign="middle" class="TableText"><div align="center">1-1/2"x.08<br>

2-1/2"x.08<br>

4"x.1</div></td>

<td valign="middle" class="TableText"><div align="center">20<br>

32<br>

79</div></td>

<td valign="middle" class="TableText"><div align="center">SPECIAL</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">PIPE</div></td>

<td valign="middle" class="TableText"><div align="center">1"x.16<br>

2"x.23<br>

4"x.31</div></td>

<td valign="middle" class="TableText"><div align="center">18<br>

39<br>

47</div></td>

<td valign="middle" class="TableText"><div align="center">SPECIAL</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" width="149" valign="middle" class="TableText"><div align="center">ROUND BAR</div></td>

<td valign="middle" class="TableText"><div align="center">Ø1.58<br>

Ø2.36<br>

Ø2.76</div></td>

<td valign="middle" class="TableText"><div align="center">16<br>

24<br>

32</div></td>

<td valign="middle" class="TableText"><div align="center">SPECIAL</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">ANGLE LEG IN</div></td>

<td valign="middle" class="TableText"><div align="center">L2x2x3/16<br>

L3x3x3/16<br>

L4x4x3/8</div></td>

<td valign="middle" class="TableText"><div align="center">28<br>

43<br>

59</div></td>

<td valign="middle" class="TableText"><div align="center">STANDARD</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">ANGLE LEG OUT</div></td>

<td valign="middle" class="TableText"><div align="center">L2x2x3/16<br>

L3x3x3/16<br>

L4x4x3/8</div></td>

<td valign="middle" class="TableText"><div align="center">28<br>

43<br>

59</div></td>

<td valign="middle" class="TableText"><div align="center">STANDARD</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">T SECTION LEG IN</div></td>

<td valign="middle" class="TableText"><div align="center">ST1.5x2.85<br>

ST3x6.25</div></td>

<td valign="middle" class="TableText"><div align="center">20<br>

36</div></td>

<td valign="middle" class="TableText"><div align="center">STANDARD</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">T SECTION LEG OUT</div></td>

<td valign="middle" class="TableText"><div align="center">ST1.5x2.85<br>

ST3x6.25</div></td>

<td valign="middle" class="TableText"><div align="center">20<br>

36</div></td>

<td valign="middle" class="TableText"><div align="center">STANDARD</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">C SECTION EASY WAY LEGS OUT</div></td>

<td valign="middle" class="TableText"><div align="center">C4x4.5<br>

C8x11.5</div></td>

<td valign="middle" class="TableText"><div align="center">24<br>

43</div></td>

<td valign="middle" class="TableText"><div align="center">STANDARD</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">C SECTION EASY WAY LEGS IN</div></td>

<td valign="middle" class="TableText"><div align="center">C4x4.5<br>

C8x11.5</div></td>

<td valign="middle" class="TableText"><div align="center">28<br>

47</div></td>

<td valign="middle" class="TableText"><div align="center">STANDARD</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">S SECTION HARD WAY</div></td>

<td valign="middle" class="TableText"><div align="center">S4x7.7</div></td>

<td valign="middle" class="TableText"><div align="center">236</div></td>

<td valign="middle" class="TableText"><div align="center">STANDARD</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">S SECTION EASY WAY</div></td>

<td valign="middle" class="TableText"><div align="center">S4x7.7</div></td>

<td valign="middle" class="TableText"><div align="center">43</div></td>

<td valign="middle" class="TableText"><div align="center">STANDARD</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">W SECTION EASY WAY</div></td>

<td valign="middle" class="TableText"><div align="center">—</div></td>

<td valign="middle" class="TableText"><div align="center">—</div></td>

<td valign="middle" class="TableText"><div align="center">—</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" valign="middle" class="TableText"><div align="center">W SECTION HARD WAY</div></td>

<td valign="middle" class="TableText"><div align="center">—</div></td>

<td valign="middle" class="TableText"><div align="center">—</div></td>

<td valign="middle" class="TableText"><div align="center">—</div></td>

</tr>

</tbody>

</table>

<p>* The specifications above are based on steel with a yield point of 36,000 PSI. GATOR reserves the right to change any of these specifications without prior notice.

</p>

<p>For other lengths and sizes please contact us

</p>

<p>Specifications are subject to change without notice.

</p>

<p>NOTE: Data is provided by the manufacturer.

</p>

<p><b>FEATURES:</b></p>

<ul>

<li><strong>TELESCOPIC FRONT SHEET PROTECTION</strong>

<ul>

<li>The telescopic front protection sheets are an important part of the bending machine that helps it last longer and work better. During bending, these sheets keep slag from getting inside the machine, protecting the bearings from damage caused by different material densities, especially lighter metals.</li>

<li>Designed by our skilled team, these layered sealed sheets help the machine run smoothly for a long time. This design not only protects the inner parts but also makes the machine easier to maintain and improves its overall performance. With these protection sheets, you can trust that your equipment will work well, even in tough conditions.</li>

</ul>

</li>

<li><strong>HYDRAULIC GUIDE ROLLS</strong>

<ul>

<li>In our profile and pipe bending machines, the GAR/60 model features mechanical guide rolls, while the GAR/80 and larger models come standard with hydraulic guide rolls. This upgrade provides users with a more precise and comfortable bending experience.</li>

</ul>

</li>

<li><strong>UPPER SHAFT SUPPORT DEVICE</strong>

<ul>

<li>The upper shaft support apparatus is designed to prevent flexing of the upper shaft. This helps avoid material buckling and ensures precise production. By protecting the upper shaft, this feature also contributes to a longer lifespan for the machine.</li>

</ul>

</li>

<li><strong>BEARING GUIDANCE SYSTEM</strong>

<ul>

<li>Our rolls are equipped with spherical roller bearings for superior guidance. This advanced bearing system requires minimal lubrication and guarantees long-term precision and reliability.</li>

</ul>

</li>

<li><strong>VARIABLE PITCH SPIRAL BENDING FEATURE</strong>

<ul>

<li>The serpentine system is essential for effective heat transfer in various industrial applications. This system efficiently manages the circulation of gases and liquids through pipes that have been bent to maximize surface area. Our GAR series incorporates a serpentine bending feature, providing our valued customers with a reliable solution for their bending needs.</li>

</ul>

</li>

<li><strong>DURABLE MACHINE BODIES</strong>

<ul>

<li>At Gator, our machine bodies are meticulously designed and reinforced to minimize plate deformation. Constructed from ST-52 quality steel, the machine frames are built for exceptional strength and durability. The entire body undergoes CNC machining, ensuring precise surface finishes and perfect parallelism across all axes. This advanced production process not only enhances the longevity of the machine but also ensures the precision of its critical components.</li>

</ul>

</li>

<li><strong>ENCODER</strong>

<ul>

<li>Our machines feature a hidden encoder designed to record rotational movement accurately while being protected against damage. This encoder ensures precise monitoring and control of turning operations. </li>

</ul>

</li>

<li><strong>MAINTENANCE LAMP

</strong>

<ul>

<li>We have made maintenance easier with an interior lighting lamp that is manageable in the touch screen menu<br>

</li>

</ul>

</li>

<li><strong>CONTROL PANEL

</strong>

<ul>

<li>3-Stage Angularly Adjustable Control Panel: Offers ease of use for the operator with customizable angles.</li>

<li>Mobile Control Panel: Equipped with wheels for easy relocation.</li>

<li>Adjustable Keypad: Designed for both horizontal and vertical machine use.</li>

<li> Sound-Light Buzzer Warning System: Provides clear alerts and notifications.</li>

<li>Bending Calculation Page: Computes the required arc and depth for precise bending control.</li>

<li>Digital Display: Shows machine operating hours.</li>

<li>Multi-Lingual Support: Available in English, German, Spanish</li>

<li>Capacity Tables: Accessible directly from the control panel for convenience.</li>

<li>Transparent Protection Cover: Safeguards the control panel while allowing visibility</li>

</ul>

</li>

<li>We are proud to be the first company to make automation a standard feature in our machines. By integrating the Numerical Control (NC) System—developed with GATOR's expertise—into our Profile, Pipe, and Sheet Bending Machines, we enhance both mass production and precision, setting a new standard in productivity.</li>

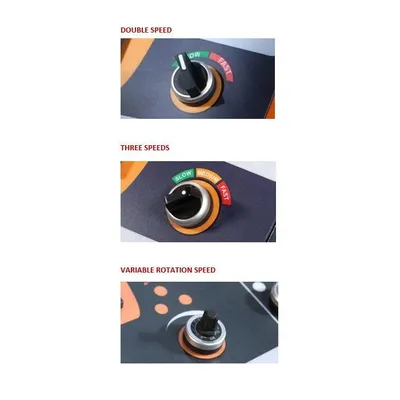

<li><strong>DOUBLE SPEED

</strong>

<ul>

<li>The GAR 60 and GAR 80 models are equipped with a double speed feature, allowing for increased efficiency and flexibility during the bending process. This capability enables users to adapt to different materials and project requirements with ease.</li>

</ul>

</li>

<li><strong>THREE SPEEDS

</strong>

<ul>

<li>The GAR/100 and GAR/120 series of angle bending machines come with a three-speed feature. This allows for enhanced versatility and control, enabling users to select the optimal speed for various materials and bending tasks.</li>

</ul>

</li>

<li><strong>VARIABLE ROTATION SPEED</strong>

<ul>

<li>The GAR/150 and larger models are equipped with a variable rotation speed feature. This allows users to adjust the speed to match specific bending requirements, providing greater flexibility and precision for different materials and applications.<br>

</li>

</ul>

</li>

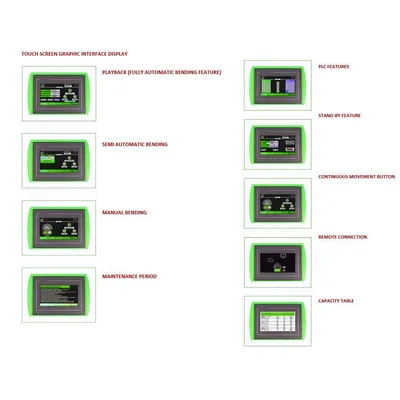

<li><strong>TOUCH SCREEN GRAPHIC INTERFACE DISPLAY

</strong>

<ul>

<li>Directing the machine for more precise bending is now effortless with our user-friendly graphic interface and advanced technology. The 7" and 10" touch screen displays enable you to perform a wide range of essential processes with ease.</li>

<li><strong>PLAYBACK (FULLY AUTOMATIC BENDING FEATURE)</strong><br>

Bending parts with consistent precision and in the same position is now simpler and more efficient. By uploading the shapes and desired diameters of the parts to the system just once, you can achieve accurate bends without requiring an experienced operator. This approach not only saves time but also ensures greater precision in your bending processes.</li>

<li><strong>SEMI AUTOMATIC BENDING</strong><br>

You can program the required shapes and diameters directly into the system based on the material characteristics, allowing the rolls to be positioned automatically. This results in more precise and higher-quality bends.</li>

<li><strong>MANUAL BENDING</strong><br>

Gator, with its manual bending feature, enables the bending of non-continuous bending by expert operators.</li>

<li><strong>MAINTENANCE PERIOD</strong><br>

It has the feature of informing the operator about the maintenance procedure to be done when the maintenance period comes.<br>

</li>

<li><strong>PLC FEATURES</strong><br>

We can diagnose possible failures faster and easier, reach a solution in a shorter time, and provide easy maintenance with the control page displaying the inputs and outputs between the PLC and the control panel.</li>

<li><strong>STAND-BY FEATURE</strong><br>

We’ve introduced a unique Stand-By feature that enhances the machine's versatility. While bending material, you can pause the operation, modify the program steps, and then resume automatic bending from the exact point where you left off with the updated program. This allows for more precise and higher-quality bending results.</li>

<li><strong>CONTINUOUS MOVEMENT BUTTON</strong><br>

All machines have a continuous movement button on the control panel. In that way, the continuous movement of rolls can be obtained during the bending</li>

<li><strong>REMOTE CONNECTION</strong><br>

We understand that time is a crucial value in today’s world. With this in mind, we leverage cutting-edge technology to support our valued customers effectively. In the event of a machine malfunction, we establish an online connection to address the issue promptly. Our remote access feature allows us to provide quick solutions by intervening directly in the machines.</li>

<li><strong>CAPACITY TABLE</strong><br>

All our profile and pipe bending machines, as well as our 4-roll plate bending machines, come with integrated capacity tables in their control panels. Each machine features its own specific capacity table, which we are proud to offer to our business partners for greater convenience and precision.</li>

</ul>

</li>

<li><strong>ENERGY SAVING WITH STANDBY FUNCTION

</strong>

<ul>

<li>Our machines feature a standby mode that reduces energy consumption. When idle, they automatically enter sleep mode, adjustable to your preferred duration (defaulting to 60 seconds). This not only minimizes idle time but also extends the machine's lifespan, making it a smart choice for efficiency and longevity</li>

</ul>

</li>

<li><strong>USER-FRIENDLY ACCESS VIA SMARTPHONE AND TABLETS</strong></li>

<li><strong>ANGLE CALCULATION MADE EASY

</strong>

<ul>

<li>Operators can easily calculate the flattening of materials to be bent using the flatten calculation page on the control panel. This feature eliminates the need for complex engineering calculations, allowing for quick and accurate adjustments right at your fingertips. This user-friendly approach streamlines the bending process and enhances productivity.<br>

</li>

</ul>

</li>

</ul>

<p><b> STANDARD FEATURES: </b></p>

<ul>

<li><strong>NC System</strong></li>

<li>PLC control with manual, semi and full automatic options</li>

<li>10'' multi-functional touch screen</li>

<li>Rectangular profile, plate hardway-easyway, square, pipe, tube, angle leg, T-section,</li>

<li>C, I, W, H, Section bending</li>

<li>Circular, elliptical, oval shapes and different diameters bendings</li>

<li>Variable speed feature</li>

<li>St-52 quality steel frame and parts</li>

<li>Hardened and grounded rolls and shafts</li>

<li>Bearing guidance system</li>

<li>Top roll and bottom rolls driven with electrical motor and variable pump capacity</li>

<li><strong>Three rolls independently driven with hydraulic motor and planetary gear box</strong></li>

<li>Oil cooling system</li>

<li>Three axes hydraulic guide rolls (up and down, forward-backward and circular)</li>

<li>Linear movement of bottom roll shafts with hydraulic system connected to body</li>

<li>Telescopic front protection sheets</li>

<li>Multi-purpose bending rolls (One set)</li>

<li>Horizontal working only</li>

<li>Serpentine bending feature</li>

<li>Continuous turning of rolls with one button</li>

<li>Hidden encoder against crushes that records turning movement</li>

<li><strong>Protection system against overloads</strong></li>

<li>Three stage mobile control panel separated from machine</li>

<li><strong>Online remote connection</strong></li>

<li>Formula page to calculate radius and deepness</li>

<li>Sound-light buzzer warning system</li>

<li>Automatic central lubrication</li>

<li><strong>Maintenance time warning page</strong></li>

<li>Alarm page that shows the warnings in machine</li>

<li>CE Certified </li>

<li>Transparent protection covers for control panel</li>

</ul>

<p><b> OPTIONAL ITEMS:</b></p>

<ul>

<li>CNC System </li>

<li>Pulling device (H,U and I sections)</li>

<li>Special rolls for different diameters</li>

<li>Digital display for hydraulic guide rolls</li>

<li>Hydraulic circular pitch device</li>

<li>Joystick control system</li>

<li>Automation system for different voltages and frequency</li>

</ul>