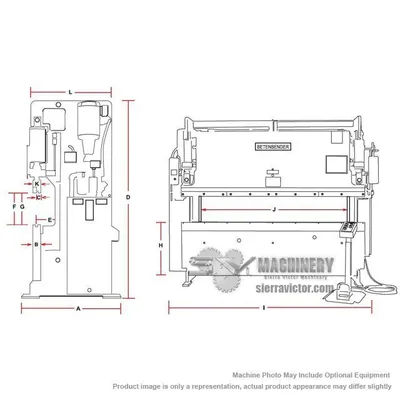

<table cellspacing="0" cellpadding="0" border="1" width="520">

<tbody style="text-align: center;">

<tr>

<td width="257" bgcolor="#cccccc" class="TableText1">

<div align="center">Overall Width (in.)

</div>

</td>

<td width="257" class="TableText1">56-1/2

</td>

</tr>

<tr>

<td bgcolor="#cccccc" class="TableText1">

<div align="center">Width of Bed (in.)

</div>

</td>

<td width="257" class="TableText1">5

</td>

</tr>

<tr>

<td bgcolor="#cccccc" class="TableText1">

<div align="center">Width of Upper Machined Ram (in.)

</div>

</td>

<td width="257" class="TableText1">2-3/4

</td>

</tr>

<tr>

<td bgcolor="#cccccc" class="TableText1">

<div align="center">Overall Height (in.)

</div>

</td>

<td width="257" class="TableText1">103

</td>

</tr>

<tr>

<td bgcolor="#cccccc" class="TableText1">

<div align="center">Throat Depth (in.)

</div>

</td>

<td class="TableText1">8

</td>

</tr>

<tr>

<td bgcolor="#cccccc" class="TableText1">

<div align="center">Open Height (in.)

</div>

</td>

<td class="TableText1">14

</td>

</tr>

<tr>

<td bgcolor="#cccccc" class="TableText1">

<div align="center">Closed Height (in.)

</div>

</td>

<td class="TableText1">6

</td>

</tr>

<tr>

<td bgcolor="#cccccc" class="TableText1">

<div align="center">Height of Bed (in.)

</div>

</td>

<td class="TableText1">37

</td>

</tr>

<tr>

<td bgcolor="#cccccc" class="TableText1">

<div align="center">Overall Length (in.)

</div>

</td>

<td class="TableText1">183

</td>

</tr>

<tr>

<td bgcolor="#cccccc" class="TableText1">

<div align="center">Distance Between Housing (in.)

</div>

</td>

<td class="TableText1">150-1/2

</td>

</tr>

<tr>

<td bgcolor="#cccccc" class="TableText1">

<div align="center">Width of Upper Ram (in.)

</div>

</td>

<td class="TableText1">3

</td>

</tr>

<tr>

<td bgcolor="#cccccc" class="TableText1">

<div align="center">Width of Upper End Plates (in.)

</div>

</td>

<td class="TableText1">50

</td>

</tr>

<tr>

<td bgcolor="#cccccc" class="TableText1">

<div align="center">Press (IPM)

</div>

</td>

<td class="TableText1">40

</td>

</tr>

<tr>

<td bgcolor="#cccccc" class="TableText1">

<div align="center">Rapid Approach (IPM)

</div>

</td>

<td class="TableText1">87

</td>

</tr>

<tr>

<td bgcolor="#cccccc" class="TableText1">

<div align="center">Return to Open (IPM)

</div>

</td>

<td class="TableText1">115

</td>

</tr>

<tr>

<td bgcolor="#cccccc" class="TableText1">

<div align="center">2-Speed Electric Shift

</div>

</td>

<td class="TableText1">Std.

</td>

</tr>

<tr>

<td bgcolor="#cccccc" class="TableText1">

<div align="center">HP

</div>

</td>

<td class="TableText1">

<div align="center">20 HP<br>

208/230v, 54amps<br>

460v, 27 amps

</div>

</td>

</tr>

<tr>

<td bgcolor="#cccccc" class="TableText1">

<div align="center">Weight (lbs.)

</div>

</td>

<td class="TableText1">26,000

</td>

</tr>

</tbody>

</table>

<p class="style12">**ESTIMATED WEIGHTS. The weight of your machine may vary from the estimated weight listed here. Weights may vary<br>

according to options included.<br>

> For specs on larger machines please call or email us and we will provide those for you.

</p>

<p class="style12">> All dimensions are in inches unless otherwise noted. (To convert to centimeters multiply by 2.54)<br>

> Engineering data and dimensions are subject to change without notice due to continuing product development.<br>

> Foundation plans are available upon request.<br>

> Die Blocks are not furnished.<br>

> To convert Horsepower to KW, multiply by 0.746

</p>

<p>Specifications are subject to change without notice.

</p>

<p>NOTE: Data is provided by the manufacturer.

</p>

<p><strong>WARRANTY: 1 YEAR</strong> – Parts

</p>

<ul>

<li>** <strong>FREE SHIPPING TO COMMERCIAL ADDRESS THAT CAN OFFLOAD**</strong></li>

<li><strong>MADE IN USA</strong></li>

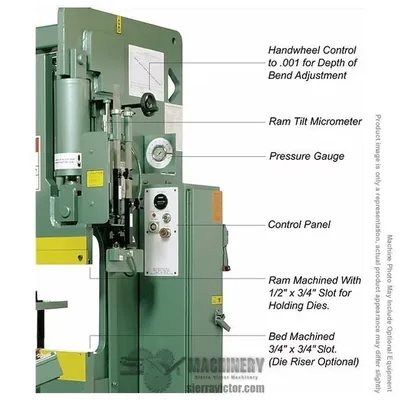

<li><strong>Frame</strong>: The frame is of open throat design with mounting holes in feet. Drilled and tapped holes in feet allow for leveling of the machine.</li>

<li><strong>Bed</strong>: The machined flat surface is slotted full length to accommodate standard die holders, filter blocks, misc.</li>

<li><strong>Front & Back of Bed</strong>: The bed is machined down 4” on the front and 12” on the back to allow a flat surface for mounting various brackets, supports and gauges.</li>

<li><strong>Ram</strong>: The ram is constructed of solid steel slotted to accept standard dies. The clamping bar is sectional for positive clamping. The upper is machined up to 4” to allow a flat surface for mounting brackets and gauges.</li>

<li><strong>Ram Tilt Adjustment</strong>: The micrometer spindle is located on the right side end frame of machine, which allows for adjustment of the desired angle required up to ±0.500 inch. The micrometer allows the operator to return to a given setting, parallel to desired angle. By using the micrometer reading, the machine can return to previous position.</li>

<li><strong>Ram Level</strong>: The ram level is accomplished by two hydraulic systems, one for each cylinder, which keeps them parallel. The ram self-levels at the bottom of each stroke even if hydraulic system is out of adjustment.</li>

<li><strong>Hydraulic Cylinders</strong>: Direct acting hydraulic cylinders are one piece, double acting with self-aligning, hardened ball sockets.</li>

<li><strong>Accuracy</strong>: Parallelism is maintained at ±0.002 inch in low speed. </li>

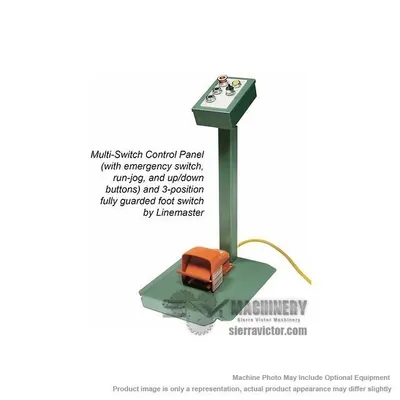

<li><strong>Operating Controls</strong>:

<ul>

<li>1. Pull to start. Push off. Light is on when in the “ON” position.</li>

<li>2. Run/Jog switch. Run position for normal operation. Jog position for loading of tooling, maintenance and set-up.<br>

Up/Down buttons are used when in jog.</li>

<li>3. 3 Position Foot Petal<br>

a. Ram up<br>

b. Ram hold<br>

c. Foot petal down. Ram down allows or jogging of ram down and holding. Emergency stop and emergency up buttons are located on a small pedestal that comes from the foot petal.</li>

<li>4. Cycle time delay at bottom of stroke</li>

</ul>

</li>

<li>*When using top & bottom tools on a press brake, a forming system is created which requires analysis to determine the appropriate safeguarding for operator safety and protection.</li>

<li>*It is the user’s responsibility to ensure that the point of operation is effective and all applicable safety requirements are met.</li>

<li><strong>Stroke Control (Optional)</strong>: Control of strokes in accomplished by rotation of hand wheels, which read in thousandths of an inch and set the closed height. When the machine is 2 or 3 speed, the knob for setting the speed change point is located on right side for simple adjustments.</li>

<li><strong>Tonnage Control (Optional)</strong>: Our machines are equipped with optional adjustable<br>

tonnage control to go from lower tonnage to rated tonnage of machine, as well as overload protection.</li>

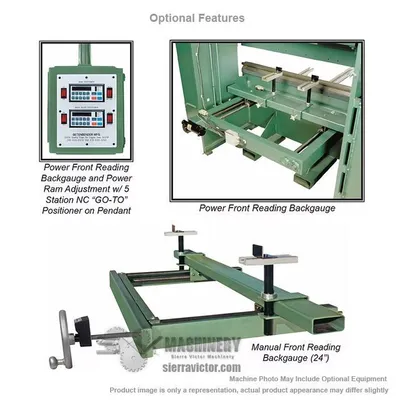

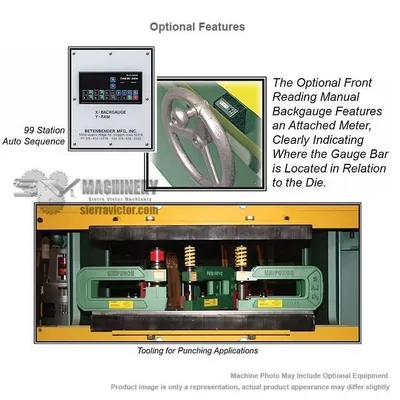

<li>Backgauge: A slide and clamp, 3 axis backgauge 24” is standard.

<ul>

<li>1. Front operated manual backgauge, hand wheel with mechanical readout (0.01)</li>

<li>2. Front operated power backgauge with LED readout (0.001)<br>

CNC backgauging and front gauging is optional.</li>

</ul>

</li>

<li><strong>Front Support Arms (Optional):</strong> 24” support arms are “slide” type. Optional disappearing stops help to hold the material from sliding backward.</li>

<li><strong>Electrical System</strong>: The electrical systems meet NFPA 79 standards. All machines have<br>

disconnect switches, magnetic starters, 110/120v controls, 208-230/460v 3 phase, others optional.</li>

<li><strong>Motors</strong>: Our American made motors are rated for continuous duty, open drip.</li>

<li><strong>Lubrication</strong>: Grease zerks are standard. One shot lube or automatic lubrication is optional.</li>

<li><strong>Safety Features</strong>: Betenbender Hydraulic Press Brakes and Shears are built to meet ANSI B11.3 standards. Safety features of the Betenbender Press Brake include:<br>

<ul>

<li> Emergency stop on pedestal</li>

<li> Emergency up on pedestal</li>

<li>Warning signs, safety markings and covers</li>

<li>Electronics meet NFPA 79 standards</li>

<li>110/120v control</li>

</ul>

</li>

<li>Specifications are subject to change withoutnotice.</li>

<li>Compliance with OSHA requirements is the legal responsibility of the user and is subject to local inspectors’ interpretation of existing standards.</li>

<li>Betenbender Shears are built to meet ANSI B11.3 standards</li>

</ul>

<p><strong>STANDARD EQUIPMENT:</strong>

</p>

<ul>

<li>Clamp Type Backgauge-Manual Adjustment X, Y, and Z</li>

<li>Two Speed Ram</li>

<li>Bottom Time Delay</li>

<li>Three Position Foot Pedal</li>

<li>Depth Stop w/Digital Readout</li>

<li>Three Speed (95T and Larger)</li>

<li>American Made Motors</li>

<li>Hour Meter</li>

<li>Nema Electrics</li>

<li>All Hydraulic Fluids Included</li>

<li>Disconnect Switch</li>

<li>All Steel Construction</li>

<li><strong>NOTE: DIE RISERS NOT FURNISHED</strong></li>

</ul>

<p><b>OPTIONAL ITEMS:</b></p>

<ul>

<li><strong>Factory Start Up by Base Service Technician ...... $1,250.00 per day plus expenses</strong></li>

<li>*24" Support Arms "Slide" Type W/T-Slots ........................ $1,200.00 pair</li>

<li> *Keylock Switch ...................................................................... $300.00</li>

<li> *Light Curtain .......................................................................... $7,500.00</li>

<li> Manual Front Reading Backgauge (24”) with Mechanical Readout .... $CALL</li>

<li> *One Shot Lubrication .......................................................... $1,100.00</li>

<li> *Operator Station Palm Control .......................................... $1,900.00</li>

<li>*Variable Tonnage Control .................................................. $1,550.00</li>

<li> *Work Light ............................................................................. $450.00</li>

<li> 208v Single Phase ............................... $CALL</li>

<li> Additional Foot Pedal with Keylock .................................... $CALL</li>

<li> Air Lift (Recommended for 4/Way Dies ............................. $CALL</li>

<li> Angle Brackets (Plates) for Bottom (4"x4") 18" Shorter than Bed ....... $300.00 per foot</li>

<li> Angle Brackets (Plates) for Top (4"x4") 18" Shorter than Bed ......... $300.00 per foot</li>

<li> Automatic Lubrication ........................................................... $3,100.00 each</li>

<li> Bed Machining Angle Brackets ........................................... $1,900.00</li>

<li> Bolt/Shim Kit for Leveling ............................................... $450.00</li>

<li> CNC Backgauge .................................. $CALL</li>

<li> CNC Ram Stop .................................... $CALL</li>

<li>Crating Charge (Not an Export Crate) Still Requires Tarping ..... P.O.R.</li>

<li> Die Riser ........................................................................ P.O.R.</li>

<li> Die Rollover Bars (Recommended for 4/Way Dies) ..... $250.00</li>

<li> Disappearing Stops (Support Arms) ............................. $200.00 each</li>

<li> Dove Tails ............................................ $CALL</li>

<li> Dual Calibration ................................. $CALL</li>

<li> Extended Support Arms (each) ....................................... $60.00 per foot</li>

<li> Extra Length on Backgauge ............................................. $CALL</li>

<li>Extra Foot Pedal w/Keylock Switch ................................. $1,000.00</li>

<li> Increase Stroke Length .................................................... P.O.R.</li>

<li> Increase Throat Gap or Increase Open Height

<ul>

<li>50, 70, 95 Ton .............. $1,000.00 per inch</li>

<li>120, 160, 190 Ton ....... $1,800.00 per inch</li>

<li>240 Ton ......................... $2,000.00 per inch</li>

</ul>

</li>

<li> Micrometer Precision Gauge Unit (2 Required) ....... $CALL</li>

<li> Oil Cooler (Kidney Loop System) .................................... $7,500.00</li>

<li> Palm Buttons/Foot Control System (Hand buttons to preset height, stop and hold, foot to continue to shut height) ................................................$3,100.00</li>

<li> Power Front Reading Backgauge with 5 Station NC “GO-TO” Positioner on Pendant ... $CALL</li>

<li> Power Ram Adjustment with 5 Station NC “GO-TO” Positioner on Pendant .... $CALL</li>

<li> Ram Machining ......................................... $1,900.00</li>

<li>Ram Stop Control (1/4" above die) .............. P.O.R.</li>

<li> Special Application Tooling .............. $CALL</li>

<li> Special Paint Colors .......................... P.O.R.</li>

<li> T-Slots .................................................. $300.00 per foot</li>

<li><strong>BACKGAUGES AND RAM CONTROL:</strong>

<ul>

<li>*Manual Front Reading Backgauge (24") w/Mechanical Readout ..... $3,500.00</li>

<li>Power Front Reading Backgauge w/5 Station NC "Go To" Positioner on Pendant ...... $5,500.00</li>

<li>Power Ram Adjustment w/5 Station NC "Go To" Positioner on Pendant ....... $2,500.00</li>

<li>Extra Length on Backgauge ............................. $1,000.00</li>

<li>CNC Backgauge ................................................. P.O.R.</li>

</ul>

</li>

</ul>

<p>Rigging, Lagging, Leveling and Electrical Hook Up is Customers Responsibility <br>

<strong>ASK ABOUT OPTIONS NOT LISTED.<br>

</strong><strong>ALL PRICES SUBJECT TO CHANGE WITHOUT NOTICE.<br>

</strong><strong>NOTE: DIE RISERS NOT FURNISHED<br>

</strong><strong>*RECOMMENDED OPTIONS</strong>

</p>