<table cellspacing="0" cellpadding="0" border="1" width="520">

<tbody style="text-align: center;">

<tr bgcolor="#333333" class="Title_white">

<td class="TableText">

<div align="center" class="Title_white_bold">

<div align="center"><span style="color: rgb(255, 255, 255);"><strong>MODEL</strong></span>

</div>

</div>

</td>

<td class="TableText">

<div align="center" class="Title_white_bold">

<div align="center"><span style="color: rgb(255, 255, 255)">STORE PRO 3015</span> </div>

</div>

</td>

</tr>

<tr>

<td bgcolor="#cccccc" width="257" class="TableText"><div align="center">Max./Min. Loading Sheet Size</div></td>

<td width="257" class="TableText"><div align="center">10' x 5' / 3.28' x 3.28'</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" width="257" class="TableText"><div align="center">Max. Sheet Weight</div></td>

<td class="TableText"><div align="center">1,322 lbs</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" width="257" class="TableText"><div align="center">Tower Height (standard)</div></td>

<td class="TableText"><div align="center">14.4', modular extension optional</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" class="TableText"><div align="center">Max. Stacking Height Per Pallet</div></td>

<td class="TableText"><div align="center">3.54" / 12.2"</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" class="TableText"><div align="center">Max. Loading Weight Per Pallet</div></td>

<td class="TableText"><div align="center">6,613 lbs</div></td>

</tr>

</tbody>

</table>

<!--StartFragment-->

<p>Specifications are subject to change without notice.</p>

<p>NOTE: Data is provided by the manufacturer.</p>

<p><strong>WARRANTY: 1 YEAR</strong> – Parts</p><ul>

<li><strong>STORAGE SYSTEMS FOR GH AND GV SERIES ONLY</strong></li>

<li><strong>Your Challenge – Our Concern:

</strong>

<ul>

<li>Hard to find labor, especially for the second or third shift.</li>

<li>Limited plant height</li>

<li>Low machine utilization and output per day</li>

<li> Difficult to manage materials and finished goods</li>

<li>Limited budget</li>

</ul>

</li>

<li>The solution is designed to help you solve those bottlenecks for the highest output. With the STORE Pro, novices and advanced users alike benefit from an affordable and user-friendly automatic solution.</li>

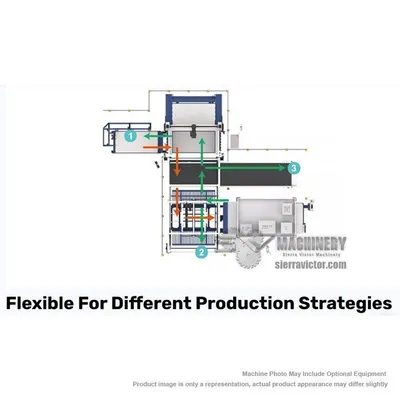

<li><strong>Flexible For Different Production Strategies:

</strong>

<ul>

<li>Flow 1: finished goods back to tower esp. in 2. or 3. shift, sorting in day shift</li>

<li>Flow 2: sorting per pallet</li>

<li>Flow 3: sorting per sheet (optional)</li>

</ul>

</li>

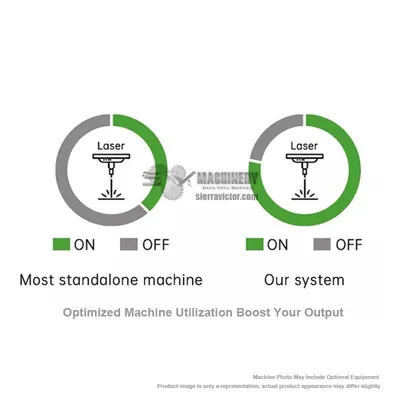

<li><strong>Optimized Machine Utilization Boost Your Output: </strong>Automation reduces waiting time for material handling by logistic staff, while our system makes the loading and unloading time even shorter by using synchronous processes. Your machine could be fully utilized, which enables you maximize your hourly output and save your money on another machine, additional space and operators.</li>

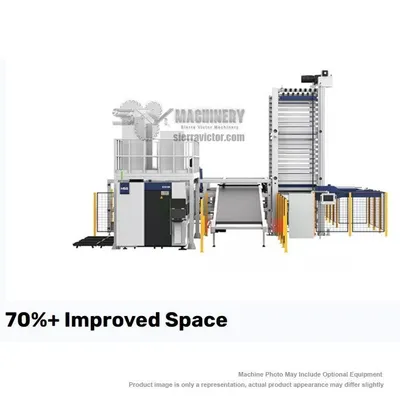

<li><strong>70%+ Improved Space: </strong>Max. 10 positions per tower with a height of 4.4m.</li>

<li><strong>Save Your Cost in Each Step: </strong>Our system could grow together with your business. The modular design enables a cost-effective extension of the automation system.

<br>

</li>

</ul>