<table cellspacing="0" cellpadding="0" border="1" width="520">

<tbody style="text-align: center;">

<tr bgcolor="#333333" class="Title_white">

<td class="TableText"><div align="center" class="Title_white_bold">

<div align="center"><span style="color: rgb(255, 255, 255);"><strong>MODEL</strong></span> </div>

</div></td>

<td class="TableText"><div align="center" class="Title_white_bold">

<div align="center"><span style="color: rgb(248, 248, 255);"><strong>G4020H</strong></span></div>

</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" width="257" class="TableText"><div align="center">Laser Power</div></td>

<td width="257" class="TableText"><div align="center">3-60kW</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" width="257" class="TableText"><div align="center">Cutting Area (L*W)</div></td>

<td class="TableText"><div align="center">4100 × 2050mm (13.45’ × 6.73’ )</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" width="257" class="TableText"><div align="center">Max. Acceleration</div></td>

<td class="TableText"><div align="center">2.8G</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" class="TableText"><div align="center">Max. No-Load Speed</div></td>

<td class="TableText"><div align="center">656 ft/min</div></td>

</tr>

<tr>

<td bgcolor="#cccccc" class="TableText"><div align="center">Max. Loading Weight</div></td>

<td class="TableText"><div align="center">5,534 (lbs)</div></td>

</tr>

</tbody>

</table>

<p>Specifications are subject to change without notice.</p>

<p>NOTE: Data is provided by the manufacturer.</p>

<p><strong>WARRANTY: 1 YEAR</strong> – Parts</p>

<ul>

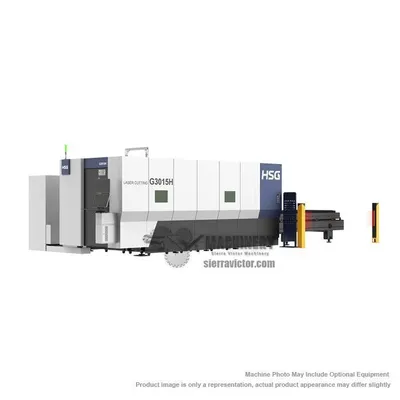

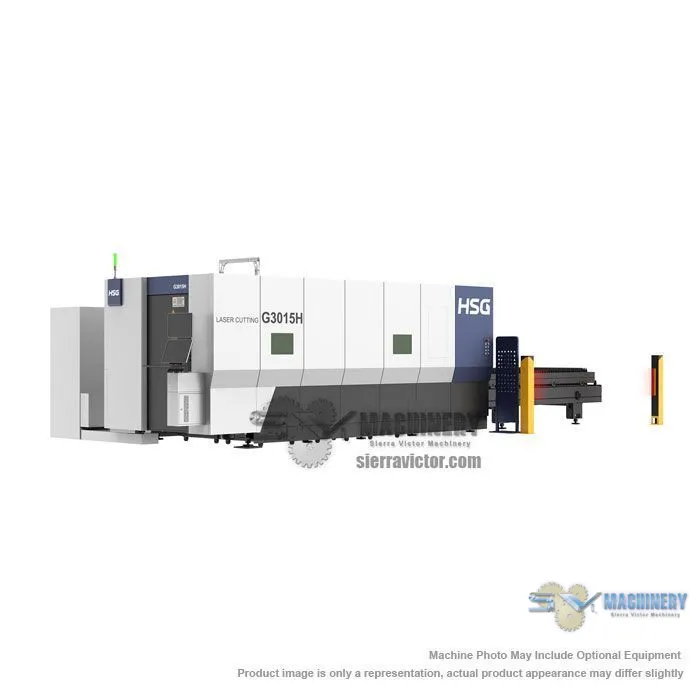

<li><strong>MAINSTREAM PRODUCTION</strong></li>

<li><strong>Built for U.S. Fabricators. Powered by HSG U.S. </strong></li>

<li><strong>A Quick Glance at the All-New GH: </strong>Looking for a cutting-edge fiber laser that strikes the perfect balance between cost-efficiency and world-class support? The GH Series delivers proven performance with over 2,000 units installed, all at a price more competitive than premium brands—while providing superior service and faster response. The all-new GH series will be the smartest investment you can make.</li>

<li><strong>Automation-Ready for Growing Shops: </strong>GH is designed for shops on the move. Whether you’re scaling up or future-proofing your workflow, the GH Series isautomation-ready, with built-in compatibility for our next generation Store Pro automation system.

<ul>

<li>Synchronized loading & unloading</li>

<li>90% machine utilization rate</li>

<li>Logistics time reduced drastically</li>

<li>Save on labor, space, and machine investment</li>

</ul>

</li>

<li><strong>Dedicated U.S. Customer Service:</strong>

<ul>

<li>PROVEN BY U.S. FABRICATORS: With over 450 U.S. installations, backed by local customer service and a growing parts network, HSG’s laser machines have proven reliability among American fabricators.</li>

<li>CUSTOMER SERVICE BY HSG U.S.: HSG’s dedicated U.S. service team stands ready to deliver rapid support whenever you need it. Rely on quick response times and on-site assistance to keep your production on schedule.</li>

<li>FAST LOCAL SPARE PARTS DELIVERY: Enjoy minimal downtime with immediate access to the spare parts you need. Our local warehouse ensure your production stays on track through fast shipping and reliable inventory.</li>

</ul>

</li>

<li><strong>Cut Smarter, Deliver Faster, Immediate Productivity</strong></li>

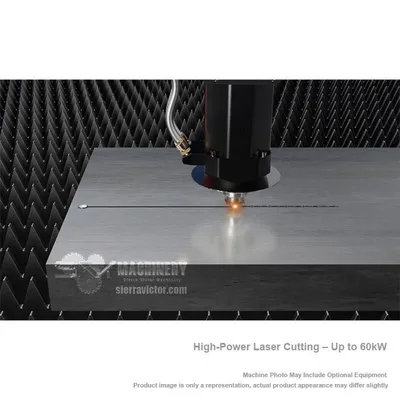

<li><strong>High Dynamics + High Power = Maximum Throughput:</strong></li>

<li>The all-new GH Series is built to outperform—with both ultra-fast acceleration and extreme power capacity up to 60kW. </li>

<li>Compared to standard 12kW systems, GH delivers up to <strong>30–40% faster cutting</strong> with significantly better gas efficiency—ideal for high-volume production environments. </li>

<li><strong>High Dynamic Motion System - Up to 4G:</strong>

<ul>

<li>Premium drives and a reinforced welded frame ensure high rigidity and cutting stability, even at top speed.</li>

<li>Acceleration of up to <strong>4G</strong> and positioning speeds up to <strong>656ft/min.</strong></li>

<li>Real-time adaptive control enables faster cornering and tighter contours without compromising precision.</li>

</ul>

</li>

<li><strong>High-Power Laser Cutting – Up to 60kW:</strong>

<ul>

<li>Cut carbon steel up to <strong>100mm (3.94”)</strong>, stainless steel up to <strong>120mm (4.72”)</strong>, and aluminum up to <strong>90mm (3.54”)</strong> with unmatched edge quality.</li>

<li> Smart piercing technology (e.g. Lightning Piercing, 25-Level Piercing Control) ensures efficient processing of thick materials with reduced slag and minimal rework.</li>

<li> Dual beam spot technology and beam shaper modules adapt automatically for thin-to-thick material transitions.</li>

</ul>

</li>

<li><strong>Variable Beam Spot</strong>: Realize stable cutting of thick sheet, easily meet the laser cutting needs of various scenarios, and improve cutting efficiency and quality. </li>

<li><strong>Automatic Centering</strong>: Detecting coaxial deviation of optical core through melt pool image and cutting process. Real time automatic coaxial adjustment ensures consistent cutting quality.</li>

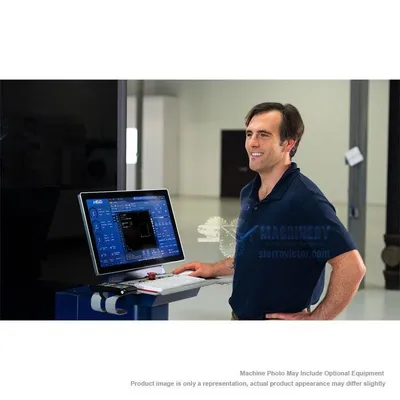

<li><strong>Easy Operation, High Throughput </strong></li>

<li><strong>All-New Touchscreen Alpha T Pro System: </strong>The GH Series runs on HSG’s all-new <strong>Alpha T Pro Bus System</strong>—a smart, robust control platform designed for ease of use. With its <strong>touchscreen interface</strong> and <strong>smartphone-style navigation</strong>, operating your laser cutter is as easy as using an iPad.

<ul>

<li>Clean UI, swipe-and-tap operation</li>

<li>Minimal training required</li>

<li>Rapid onboarding for any operator</li>

</ul>

</li>

<li><strong>Programing Has Never Been This User-Friendly: </strong>Alpha T Pro simplifies cutting like never before. Whether you’re starting a new job or working with leftover materials, the system guides you every step of the way. </li>

<li>With Alpha T Pro, the GH Series brings advanced laser cutting power to your shop—without adding complexity to your workflow. </li>

<li><strong>HSG AR+ Vision Technology:</strong></li>

<li><strong>AR+ Visual Edge Detection</strong>: Equipped with visual AR recognition technology, it can automatically recognize the contour of the sheet, reducing production waiting time and labor costs.</li>

<li><strong>AR+ Visual Residual Function</strong>: Automatically identify the remaining materials on the board and plan the optimal cutting path to maximize the use of residual materials and reduce material waste.</li>

<li><strong>Designed for Meet U.S. Fabrication Standards</strong></li>

<li><strong>U.S. Standard Size, Materials, Gas Compatibility & Preloaded Library</strong>

<ul>

<li>10’ x 5’ standard bed size – perfect for North American sheet formats</li>

<li>Preloaded imperial material library for plug-and-play operation*</li>

<li><strong>Broad material support:</strong></li>

<li>Mild steel (up to 3.94”)</li>

<li>Mild steel (up to 3.94”)</li>

<li>Aluminum (up to 3.54”)</li>

<li>Copper and brass</li>

<li>Fully compatible with mixed gas and low-pressure nitrogen gas-saving cutting modes</li>

<li>*Customizable material settings available upon request</li>

</ul>

</li>

<li><strong>Protect your people. Protect your productivity: </strong>The GH Series is fully enclosed and engineered to meet U.S. safety standards, with TUV CE-certified, FDA compliance (in progress). From full enclosure for operator safety to fully upgraded dust extraction system, every machine prioritizes operator safety and air quality—giving you peace of mind and a cleaner, safer shop floor.</li>

<li><strong>Real Fabricators. Real Results: </strong>Hundreds of U.S. shops are already using GH Series to push productivity higher than ever. Unlike other OEMs, HSG doesn’t just sell machines—we partner in your success. Welcome to contact us for a live demo, U.S. customer references, or a customized ROI analysis.</li>

</ul>

<p><strong>STANDARD FEATURES:</strong>

</p>

<ul>

<li><strong>Visual AR recognition system: </strong>High-precision recognition is achieved through AR technology to ensure recognition accuracy and processing stability.</li>

<li><strong>Three-way valve</strong>: Air and nitrogen can be switched within the operation screen without manual switching, and the interface of the three-way valve is clearly marked.</li>

<li><strong>CypNest Software</strong>: Simple operations and powerful algorithms improve production efficiency.</li>

<li><strong>OD6 glass</strong>: Block most of the laser energy to protect the eyes from harm.</li>

<li><strong>Nozzle Automatic Change</strong>: Save time on manual nozzle changed and improve processing efficiency.</li>

<li><strong>Reserved Automation Interface</strong>: Automated solutions such as sychronous loading and unloading device,storage, etc. can be selected according to your needs.</li>

</ul>

<p><b>OPTIONAL ITEMS:</b></p>

<ul>

<li> <strong>Store Pro:</strong> Premium Intelligent Laser Automatic System</li>

<li><strong>ALG Pro:</strong> Premium Automatic Loading and Unloading System</li>

<li><strong>Store: </strong>Tower Storage System for Sheets</li>

<li><strong>ALG:</strong> Automatic Loading and Unloading System </li>

</ul>