<table width="520" cellspacing="0" cellpadding="0" border="1">

<tbody style="text-align: center;">

<tr>

<td class="Title_white_bold" valign="middle" bgcolor="#333333">

<div><span style="color: #ffffff;"><strong>MODEL</strong></span>

</div>

</td>

<td class="Title_white_bold" width="244" valign="middle" bgcolor="#333333">

<div><span style="color: #ffffff;"><strong>LM1014-FC</strong></span></div>

</td>

</tr>

<tr>

<td class="TableText" width="270" valign="middle" bgcolor="#cccccc">

<div>Maximum shearing capacity, Mild Steel

</div>

</td>

<td class="TableText" valign="middle">

<div>14 gauge

</div>

</td>

</tr>

<tr>

<td class="TableText" valign="middle" bgcolor="#cccccc">

<div>Maximum shearing capacity, Stainless Steel

</div>

</td>

<td class="TableText" valign="middle">

<div>18 gauge

</div>

</td>

</tr>

<tr>

<td class="TableText" valign="middle" bgcolor="#cccccc">

<div>Maximum cutting length

</div>

</td>

<td class="TableText" valign="middle">

<div>121"

</div>

</td>

</tr>

<tr>

<td class="TableText" valign="middle" bgcolor="#cccccc">

<div>Back gauge range

</div>

</td>

<td class="TableText" valign="middle">

<div>30" / 762mm

</div>

</td>

</tr>

<tr>

<td class="TableText" valign="middle" bgcolor="#cccccc">

<div>Strokes per minute, full length

</div>

</td>

<td class="TableText" valign="middle">

<div>35

</div>

</td>

</tr>

<tr>

<td class="TableText" valign="middle" bgcolor="#cccccc">

<div>Number of hold down feet

</div>

</td>

<td class="TableText" valign="middle">

<div>16

</div>

</td>

</tr>

<tr>

<td class="TableText" valign="middle" bgcolor="#cccccc">

<div>Motor - 230 or 460V, 3-Phase, 60Hz (specify)

</div>

</td>

<td class="TableText" valign="middle">

<div>5 HP

</div>

</td>

</tr>

<tr>

<td class="TableText" valign="middle" bgcolor="#cccccc">

<div>

<div align="center">Floor Space, Gauges in Position

</div>

</div>

</td>

<td class="TableText" valign="middle">

<div>

<div align="center">139" x 60" x 55-1/2"

</div>

</div>

</td>

</tr>

<tr>

<td class="TableText" valign="middle" bgcolor="#cccccc">

<div align="center">Overall Dimensions, Less Gauges, LxWxH

</div>

</td>

<td class="TableText" valign="middle">

<div align="center">139" x 27" x 55-1/2"

</div>

</td>

</tr>

<tr>

<td class="TableText" valign="middle" bgcolor="#cccccc">

<div>Shipping Weight:

</div>

</td>

<td class="TableText" valign="middle">

<div>6,200 lbs.

</div>

</td>

</tr>

</tbody>

</table>

<p>*Mild Steel Rated Materials at 80,000 Tensile / 44,000 Yield

</p>

<p>** Stainless Steel Rated Materials at 90,000 Tensile / 55,000 Yield

</p>

<p>Specifications are subject to change without notice.

</p>

<p>NOTE: Data is provided by the manufacturer.

</p>

<p><strong>WARRANTY: 3 YEAR</strong> – Limited

</p>

<p></p>

<ul>

<li><strong>MADE IN USA</strong></li>

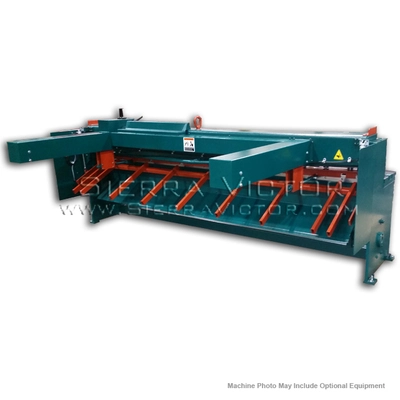

<li>LM Series mechanical shears utilize a simple low maintenance design, coupled with an array of standard features for an attractive combination of high value and solid performance.</li>

<li>The LM1014 incorporates the unique 2x back gauge system. This allows the operator to move the backstop from 0 to 30 inches in approximately 2 seconds with only two rotations of the handle. The LM 2x back-gauge can be ordered with an optional digital readout. The 2x digital readout increments are 0.001”</li>

<li>The LM Series shears are standard with four-edge, high carbon, high chrome top and bottom blades , independent, self-leveling hold down feet with neoprene inserts, single, continuous and jog stroke cycles, motor reverse switch, precision-machined table with hand well, dual inch/metric inlaid bed scales and non-metallic gibs.</li>

<li>The LM1014 capacities are 14-gauge mild steel, 18-gauge stainless up to 121 inches in cutting length. To enhance productivity, optional equipment available for the machine includes: five or ten-foot squaring arm, front support arms, light beam and protractor attachments. </li>

<li>LM1014 can be order with an optional air operated sheet support system. This system is available in two styles: System-R drops the support material to the rear of the machine; System-F returns the supported material to the front of the machine via a front return chute.</li>

<li>The LM series shears are available in a reduced price “Performance Package” configuration. The Performance Package includes: a Five Foot Squaring Arm, a pair of Front Support Arms, and Air Operated Sheet Support System. Performance “R” system is for rear return, Performance “F” system is for front return. A moveable Material Cart is available for both Front and Rear Return machines. Please call for details. </li>

<li>Please contact <strong>Sierra Victor Industries 386-304-3720</strong> for a details and a complete listing of optional equipment</li>

<li>The LM Series<strong> </strong>Performance Packages include: Five Foot Squaring Arm, Two Front Support Arms and Air Operated Sheet Support System. “R” Rear Drop Support “F” Front Return Support System “C” with Material Cart </li>

<li>

<strong>Note:</strong> Performance Packages

are Preferred Options

</li>

</ul>

<p><b>OPTIONAL ITEMS:</b></p>

<ul>

<li>Wired for CSA Canadian Electrical Standard: $415.00</li>

<li>83800: Squaring Arm Five Foot with Dual Inlaid Inch/Metric Scale: $1,180.00</li>

<li>83805: Squaring Arm Ten Foot with dual Inlaid Inch/Metric Scale: $2,655.00</li>

<li>83815: Additional Flip-up Stops for Squaring Arm (each): $230.00</li>

<li>83820: Front Support Arms Pair: $310.00</li>

<li>83825: T-Slotted Table with Two Front Support Arms with Inlaid Inch/Metric Scales: $2,125.00</li>

<li>83830: Additional Flip-up Stops for T-Slotted Support Arms and Table (each): $215.00</li>

<li>83835: Power Back-gauge 30-Inch Travel: $6,570.00</li>

<li>83840: Protractor Attachment: $685.00</li>

<li>83885: Work Shadow Light LM Series: $970.00</li>

<li>83895: Digital Readout for 2x Back-gauge System: $1,150.00</li>

<li>83890: Stroke Counter (Electro-Mechanical): $340.00</li>

<li>83900: LM1014 High Carbon High Chrome 4 Edge per set: $2,415.00</li>

</ul>

<ul>

<li><strong>Increased Cutting Speeds (Please consult factory)</strong></li>

<li>

<strong>Note:</strong> Performance Packages

are Preferred Options

</li>

</ul>