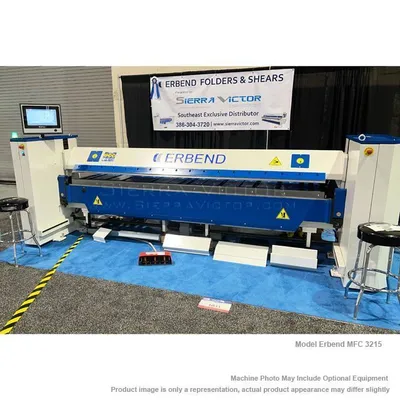

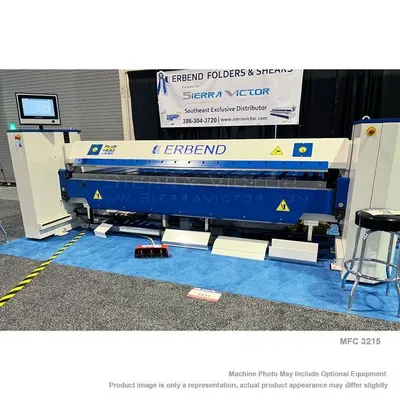

The ERBEND MFC3215 is a 10 ft x 16 ga. CNC Motorized Sheet Metal Folding Machine in the metal fabrication marketplace in North America. 7.08 inch opening height capacity on the upper beam. ERFOLD BASIC CNC LBL Cnc control software on 15.6" touchscreen controller with swivel arm. 29.5 inch servo backgauge system with feather grooves.

Specifications are subject to change without notice.

NOTE: Data is provided by the manufacturer.

WARRANTY: 1 YEAR – Parts

Optional Items - Call for price:

39.37 or 59 inch servo backgauge system with rectangular sheet support table.

2.36 or 3.54 inch high segmented goat foot tool set.

Manual crowning system.

Servo folding beam adjustment.

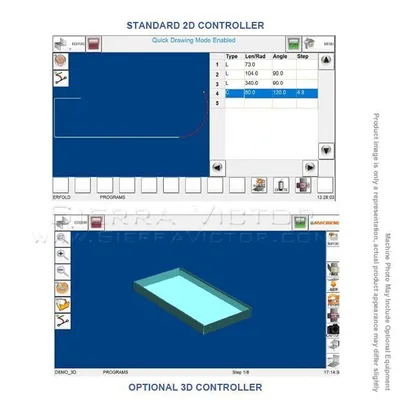

ERFOLD ADVANCED 2D/3D Cnc Graphic Control Software.

Omega geometry upgrade on lower and folding beam.

Manual conical backgauge finger.

Motorized conical backgauge system.

Pneumatic goat foot tool quick clamping system

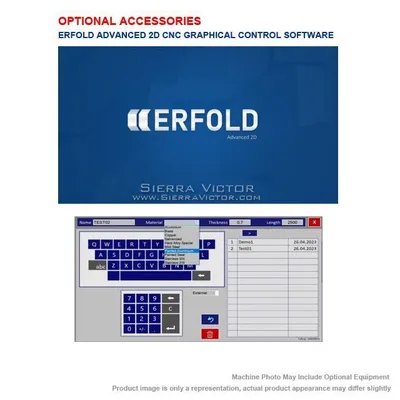

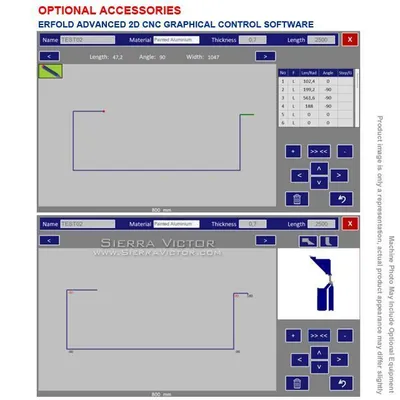

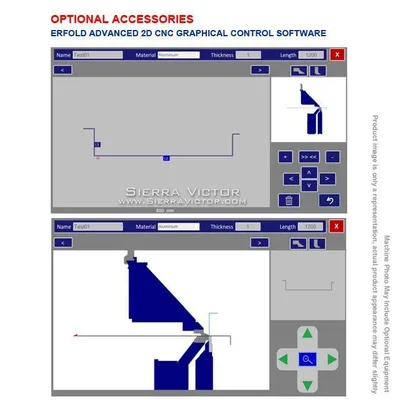

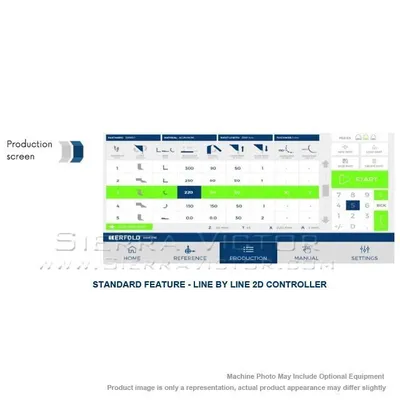

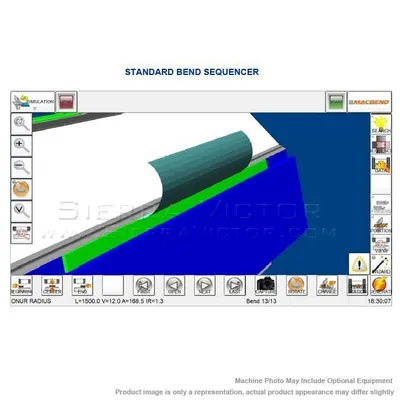

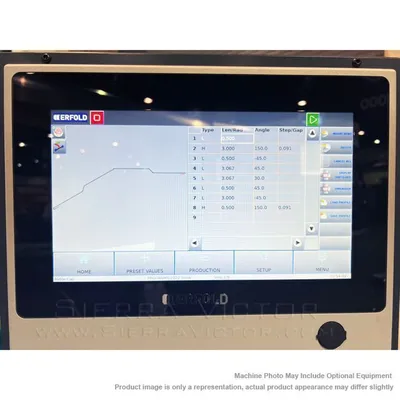

ERFOLD ADVANCED 2D CNC GRAPHICAL CONTROL SOFTWARE

Windows based software specificly designed for folders and %100 owned by Erbend

15.6" capacitve LED touchscreen controller on swivel arm

LBL Editor: You can adjust the bending steps line by line by entering the numeric values of axis targets or measures.

2D part editor: you can create a new bending programme by drawing in graphic mode and visualize in 2D graphical screen

You can determine and change the bending sequence on the created part while you are making graphical collision control

Capability of choosing material type, thickness, springback, bending correction and creating data base for every type of material type,thickness and length

Authorization with password

128 GB hard disk space which allows you to save unlimited data

Detailed alarm,tooling and parameters page

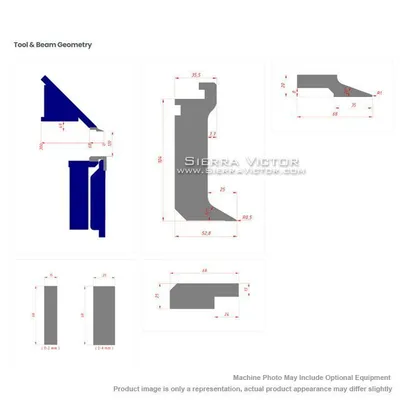

LOWER AND FOLDING BEAM WITH OMEGA GEOMETRY

Thanks to the special design and more clearence with omega beam geometry of lower beam and folding beam, the parts with downwards flanges, like omega profiles, trapezoidal profiles can be executed more easily.

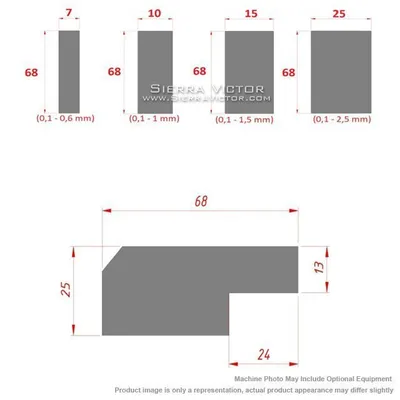

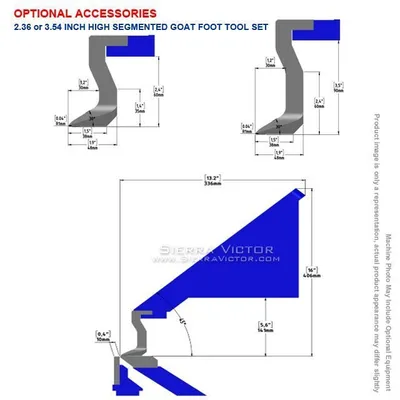

2.36 or 3.54 INCH HIGH SEGMENTED GOAT FOOT TOOL SET

MANUAL CROWNING SYSTEM

On long and thin sheets, in order to prevent the banana shape bends, you just need to adjust the crowning between %25 and %100 to give more support from the middle side of the folding beam

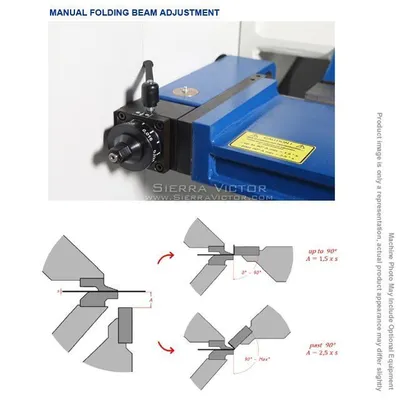

SERVO FOLDING BEAM ADJUSTMENT ( A1-A2 AXIS)

Servo driven and cnc controlled folding beam height. Your bending height is calculated automatically according to the parameters and set just before the bend.

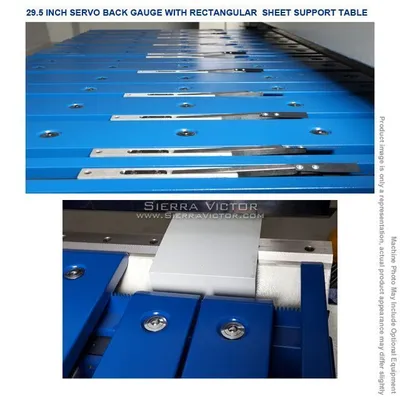

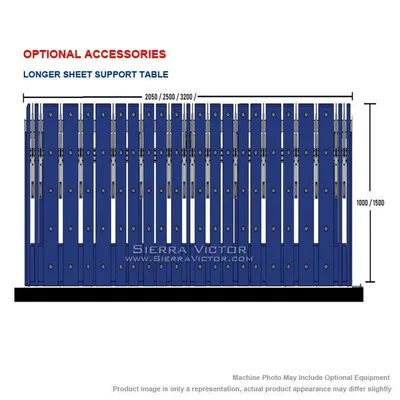

LONGER SHEET SUPPORT TABLE

39.37 or 59 inch rectangular sheet support table and back gauges

Front side gauging arms + middle and back side triangle fingers

Movable sliders for down flanges + steady side gauge

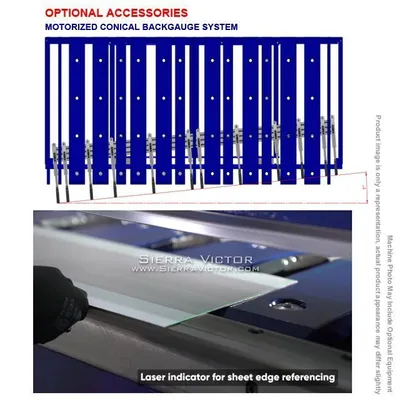

MOTORIZED CONICAL BACKGAUGE SYSTEM

Dual axis cnc servo motorized control of the backgauge as X1 and X2 axis

X1 remains fixed, X2 moves forward to create max 5° conical angle

Laser beam indicator for the reference line of the sheet edge on the lower beam (manually placed on the sliding rail regarding the software’s indication of edge position)

SUCTION CUPS ON THE TABLE SUCTION CUPS ON THE TABLE

Thanks to the suction cups placed on the front gauging group;

Misalignment of the sheet is avoided.

Dropping down of the sheet because of downwards flanges is avoided.

No need to support the sheet anymore from the front side during multi radius bends.

If the gauging side of the sheet is oval or can not be gauged well to the standard fingers/gauges, you do not need to adjust it again in each bending step.

We use cookies to improve your experience. Privacy Policy.