EDWARDS IW55 55 Ton Ironworker w/PowerLink and Coper Notcher | 230v, 3-Phase

Or as low as $2,977.35 USD/month over 36 months

Or as low as $2,977.35 USD/month over 36 months

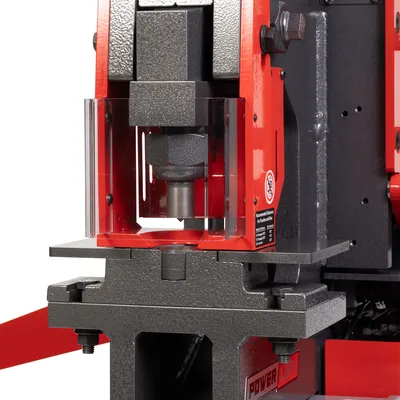

The Edwards 55 Ton Ironworker for sale standard features include a Punch Assembly with Pedestal Die Table, Flat Bar Shear, Angle Shear and a universal open tooling station designed to accept optional Tooling Accessories.The optional Hydraulic Accessory Pack allows your Ironworker to act as a power source to our expanding line of innovative Hydraulic Accessory Tools, such as the 10 Ton Tube/Pipe Bender, 20 Ton Shop Press and 40 Ton Shop Press.It has four available workstations, Universal Open Tooling Station and Electric Stroke Control.

Specifications are subject to change without notice.

NOTE: Data is provided by the manufacturer.

WARRANTY: 1 YEAR – Parts

Machine Photo May Include Optional Equipment

Product image is only a representation, actual product appearance may differ slightly

Optional Models:

ED9-IW55-3P230-A: 55 Ton Ironworker 3 Phase, 230 Volt with PowerLink

ED9-IW55-3P208-A: 55 Ton Ironworker 3 Phase, 208 Volt with PowerLink

ED9-IW55-1P230-A: 55 Ton Ironworker 1 Phase, 230 Volt with PowerLink

ED9-IW55-3P460-A: 55 Ton Ironworker 3 Phase, 460 Volt with PowerLink

ED9-IW55-3P575-A: 55 Ton Ironworker 3 Phase, 575 Volt with PowerLink

ED9-55231512: 55 Ton Ironworker 1 Phase, 230 Volt, PowerLink, Coper Notcher

ED9-55233512: 55 Ton Ironworker 3 Phase, 230 Volt, PowerLink, Coper Notcher

ED9-55203512: 55 Ton Ironworker 3 Phase, 208 Volt, PowerLink, Coper Notcher

ED9-55231522: 55 Ton Ironworker 1 Phase, 230 Volt, PowerLink, 10" Brake

ED9-55203522: 55 Ton Ironworker 3 Phase, 208 Volt, PowerLink, 10" Brake

ED9-55233522: 55 Ton Ironworker 3 Phase, 230 Volt, PowerLink, 10" Brake

Optional Items - Call for price:

Optional Attachments:

ED9-PRB12: Press Brake Tooling 12" Press Brake

ED9-HAT1000: 10 Ton Tube/Pipe Bender

ED9-HAT5000: Radius Roller

General Productivity Pack:

* Increase your Punching Efficiency and Accuracy

* AC2200 General Productivity Pack for 40TC - 100 IW

* AC2250 General Productivity Pack for 100T DLX & 120T IW

* FLEXIBILITY

- Contains Punches and Dies to produce the following size round holes: 3/16". 5/16", 7/16", 1/2", 9/16", 5/8", 11/16", 13/16", 15/16", and 1-1/16"

- The Back Gauge utilizes a positive stop attachment that is fitted to the back of the Ironworker ensuing accurate shearing out to 48"

* PRODUCTIVITY

- Punch and Die Storage Tray easily mounts to either side of the output shoot

- The 48" Back Gauge speeds up production on repeatable cuts by providing an adjustable stop for the flat bar shear and angle shear.

- The Fabricator’s protractor increase accuracy on the punch and flat bar shear workstations by guiding your work piece and is gauged at 15° increments through 180° featuring a straight edge and reversible design

- A Gauging table kit includes adjustable fences and handles quickly and easily guide your material for perfect repeatable actions

* SAFETY

- Punch diameter must meet or exceed the thickness of your material

- Super bright LED light with M12 connections has a powerful magnetic base allowing users to attach the light to any Ironworker surface and move as needed.

* PERFORMANCE

- Made of durable steel for long life

- Long lasting averages between 3,000 and 5,000 impacts

We use cookies to improve your experience. Privacy Policy.