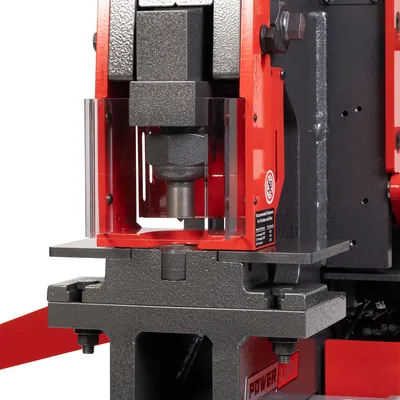

EDWARDS IW55 55 Ton Ironworker w/PowerLink | 460v, 3-Phase

Or as low as $2,740.35 USD/month over 36 months

Or as low as $2,740.35 USD/month over 36 months

The Edwards 55 Ton Ironworker for sale standard features include a Punch Assembly with Pedestal Die Table, Flat Bar Shear, Angle Shear and a universal open tooling station designed to accept optional Tooling Accessories.The optional Hydraulic Accessory Pack allows your Ironworker to act as a power source to our expanding line of innovative Hydraulic Accessory Tools, such as the 10 Ton Tube/Pipe Bender, 20 Ton Shop Press and 40 Ton Shop Press.It has four available workstations, Universal Open Tooling Station and Electric Stroke Control.

* Optional

Specifications are subject to change without notice.

NOTE: Data is provided by the manufacturer.

WARRANTY: 1 YEAR – Parts

Machine Photo May Include Optional Equipment

Product image is only a representation, actual product appearance may differ slightly

Optional Models:

ED9-IW55-3P230-A: 55 Ton Ironworker 3 Phase, 230 Volt with PowerLink

ED9-IW55-3P208-A: 55 Ton Ironworker 3 Phase, 208 Volt with PowerLink

ED9-IW55-1P230-A: 55 Ton Ironworker 1 Phase, 230 Volt with PowerLink

ED9-IW55-3P460-A: 55 Ton Ironworker 3 Phase, 460 Volt with PowerLink

ED9-IW55-3P575-A: 55 Ton Ironworker 3 Phase, 575 Volt with PowerLink

ED9-55231512: 55 Ton Ironworker 1 Phase, 230 Volt, PowerLink, Coper Notcher

ED9-55233512: 55 Ton Ironworker 3 Phase, 230 Volt, PowerLink, Coper Notcher

ED9-55203512: 55 Ton Ironworker 3 Phase, 208 Volt, PowerLink, Coper Notcher

ED9-55231522: 55 Ton Ironworker 1 Phase, 230 Volt, PowerLink, 10" Brake

ED9-55203522: 55 Ton Ironworker 3 Phase, 208 Volt, PowerLink, 10" Brake

ED9-55233522: 55 Ton Ironworker 3 Phase, 230 Volt, PowerLink, 10" Brake

Optional Items - Call for price:

Optional Attachments:

ED9-PRB12: Press Brake Tooling 12" Press Brake

ED9-HAT1000: 10 Ton Tube/Pipe Bender

ED9-HAT5000: Radius Roller

General Productivity Pack:

* Increase your Punching Efficiency and Accuracy

* AC2200 General Productivity Pack for 40TC - 100 IW

* AC2250 General Productivity Pack for 100T DLX & 120T IW

* FLEXIBILITY

- Contains Punches and Dies to produce the following size round holes: 3/16". 5/16", 7/16", 1/2", 9/16", 5/8", 11/16", 13/16", 15/16", and 1-1/16"

- The Back Gauge utilizes a positive stop attachment that is fitted to the back of the Ironworker ensuing accurate shearing out to 48"

* PRODUCTIVITY

- Punch and Die Storage Tray easily mounts to either side of the output shoot

- The 48" Back Gauge speeds up production on repeatable cuts by providing an adjustable stop for the flat bar shear and angle shear.

- The Fabricator’s protractor increase accuracy on the punch and flat bar shear workstations by guiding your work piece and is gauged at 15° increments through 180° featuring a straight edge and reversible design

- A Gauging table kit includes adjustable fences and handles quickly and easily guide your material for perfect repeatable actions

* SAFETY

- Punch diameter must meet or exceed the thickness of your material

- Super bright LED light with M12 connections has a powerful magnetic base allowing users to attach the light to any Ironworker surface and move as needed.

* PERFORMANCE

- Made of durable steel for long life

- Long lasting averages between 3,000 and 5,000 impacts

We use cookies to improve your experience. Privacy Policy.