<table cellspacing="0" cellpadding="0" border="1" width="520">

<tbody style="text-align: center;">

<tr>

<td colspan="2" valign="middle" bgcolor="#333333" class="TableText">

<div align="center" class="Title_white_bold">

<div align="center"><span style="color: rgb(255, 255, 255);"><strong>MODEL</strong></span>

</div>

</div>

</td>

<td width="257" valign="middle" bgcolor="#333333" class="Title_white_bold">

<div align="center"><span style="color: rgb(255, 255, 255);"><strong>TDC-400CNC</strong></span>

</div>

</td>

</tr>

<tr>

<td colspan="2" valign="middle" bgcolor="#cccccc" class="TableText">

<div align="center">Machine Capacity

</div>

</td>

<td valign="middle" class="TableText">

<div align="center">w 16 x h 16 in. (400mm x 400mm)

</div>

</td>

</tr>

<tr>

<td colspan="2" valign="middle" bgcolor="#cccccc" class="TableText">

<div align="center">Machine Capacity Round Tube

</div>

</td>

<td valign="middle" class="TableText">

<div align="center">16 in. (400mm)

</div>

</td>

</tr>

<tr>

<td colspan="2" valign="middle" bgcolor="#cccccc" class="TableText">

<div align="center">Production Level

</div>

</td>

<td valign="middle" class="TableText">

<div align="center">Extreme

</div>

</td>

</tr>

<tr>

<td colspan="2" valign="middle" bgcolor="#cccccc" class="TableText">

<div align="center">Saw Blade - Width x Length

</div>

</td>

<td valign="middle" class="TableText">

<div align="center">1-1/4 x 178 in.

</div>

</td>

</tr>

<tr>

<td width="127" rowspan="3" valign="middle" bgcolor="#cccccc" class="TableText">

<div align="center">Band Drive

</div>

</td>

<td valign="middle" bgcolor="#cccccc" class="TableText">

<div align="center">Motor HP

</div>

</td>

<td valign="middle" class="TableText">

<div align="center">4 Hp

</div>

</td>

</tr>

<tr>

<td valign="middle" bgcolor="#cccccc" class="TableText">

<div align="center">Band Speed

</div>

</td>

<td valign="middle" class="TableText">

<div align="center">65-328 fpm

</div>

</td>

</tr>

<tr>

<td width="128" valign="middle" bgcolor="#cccccc" class="TableText">

<div align="center">Band Tension

</div>

</td>

<td valign="middle" class="TableText">

<div align="center">Hydraulic

</div>

</td>

</tr>

<tr>

<td rowspan="2" valign="middle" bgcolor="#cccccc" class="TableText">

<div align="center">Hydraulic System

</div>

</td>

<td valign="middle" bgcolor="#cccccc" class="TableText">

<div align="center">Motor HP

</div>

</td>

<td valign="middle" class="TableText">

<div align="center">1 Hp

</div>

</td>

</tr>

<tr>

<td valign="middle" bgcolor="#cccccc" class="TableText">

<div align="center">Reservoir Size

</div>

</td>

<td valign="middle" class="TableText">

<div align="center">10 Gallon

</div>

</td>

</tr>

<tr>

<td rowspan="4" valign="middle" bgcolor="#cccccc" class="TableText">

<div align="center">Coolant System

</div>

</td>

<td valign="middle" bgcolor="#cccccc" class="TableText">

<div align="center">Flood

</div>

</td>

<td valign="middle" class="TableText">

<div align="center">Yes

</div>

</td>

</tr>

<tr>

<td valign="middle" bgcolor="#cccccc" class="TableText">

<div align="center">Mist Lubricator

</div>

</td>

<td valign="middle" class="TableText">

<div align="center">Yes

</div>

</td>

</tr>

<tr>

<td valign="middle" bgcolor="#cccccc" class="TableText">

<div align="center">Motor HP

</div>

</td>

<td valign="middle" class="TableText">

<div align="center">0.12 Hp

</div>

</td>

</tr>

<tr>

<td valign="middle" bgcolor="#cccccc" class="TableText">

<div align="center">Reservoir Size

</div>

</td>

<td valign="middle" class="TableText">

<div align="center">16 Gallon

</div>

</td>

</tr>

<tr>

<td rowspan="3" valign="middle" bgcolor="#cccccc" class="TableText">

<div align="center">Indexer

</div>

</td>

<td valign="middle" bgcolor="#cccccc" class="TableText">

<div align="center">Length per Stroke

</div>

</td>

<td valign="middle" class="TableText">

<div align="center">19.9 in.

</div>

</td>

</tr>

<tr>

<td valign="middle" bgcolor="#cccccc" class="TableText">

<div align="center">Maximum Index Strokes Length

</div>

</td>

<td valign="middle" class="TableText">

<div align="center">394 in.

</div>

</td>

</tr>

<tr>

<td valign="middle" bgcolor="#cccccc" class="TableText">

<div align="center">Remnant Length

</div>

</td>

<td valign="middle" class="TableText">

<div align="center">6 in.

</div>

</td>

</tr>

<tr>

<td rowspan="3" valign="middle" bgcolor="#cccccc" class="TableText">

<div align="center">Floor Space Dimensions

</div>

</td>

<td valign="middle" bgcolor="#cccccc" class="TableText">

<div align="center">W x L X H

</div>

</td>

<td valign="middle" class="TableText">

<div align="center">102 x 102 x 72 in.

</div>

</td>

</tr>

<tr>

<td valign="middle" bgcolor="#cccccc" class="TableText">

<div align="center">Material Pass Height

</div>

</td>

<td valign="middle" class="TableText">

<div align="center">31.5 in.

</div>

</td>

</tr>

<tr>

<td valign="middle" bgcolor="#cccccc" class="TableText">

<div align="center">Machine Weight

</div>

</td>

<td valign="middle" class="TableText">

<div align="center">2,866 lbs.

</div>

</td>

</tr>

<tr>

<td rowspan="2" valign="middle" bgcolor="#cccccc" class="TableText">

<div align="center">Electrical

</div>

</td>

<td valign="middle" bgcolor="#cccccc" class="TableText">

<div align="center">Voltage Requirement

</div>

</td>

<td valign="middle" class="TableText">

<div align="center">460V-60Hz-3ph, Wye configuration

</div>

</td>

</tr>

<tr>

<td valign="middle" bgcolor="#cccccc" class="TableText">

<div align="center">Total Amp Draw (FLA)

</div>

</td>

<td valign="middle" class="TableText">

<div align="center">9.8 Amps

</div>

</td>

</tr>

<tr>

<td colspan="2" valign="middle" bgcolor="#cccccc" class="TableText">

<div align="center">Conveyor width (cylinder)

</div>

</td>

<td valign="middle" class="TableText">

<div align="center">17.75 in. (450mm)

</div>

</td>

</tr>

<tr>

<td colspan="2" valign="middle" bgcolor="#cccccc" class="TableText">

<div align="center">Remnant Length Drop

</div>

</td>

<td valign="middle" class="TableText">

<div align="center">6 in. (150mm)

</div>

</td>

</tr>

</tbody>

</table>

<p>Specifications are subject to change without notice.

</p>

<p>NOTE: Data is provided by the manufacturer.

</p>

<p><strong>WARRANTY: 1 YEAR</strong> – Parts

</p>

<ul>

<li> Machine Capacity: w 16” x h 16" (400mm x 400mm) </li>

<li> Machine Capacity Round Tube: 16" (400mm) </li>

<li> Production Level: Extreme </li>

<li><strong>Standard Features: Mitsubishi Automatic Controls, Work Height Sensors and Variable Vise Pressure Control</strong></li>

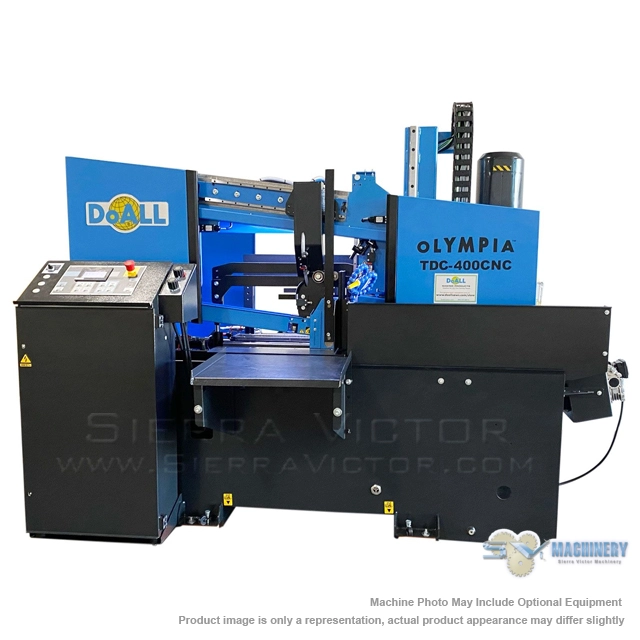

<li>The DoALL TDC-400CNC is a highly efficient hydraulically controlled band-saw with multiple material feed. It is equipped with a programmable digital Mitsubishi controller, so the blade, as well as the indexer movement, is fully automated. The operator simply programs the required specifications and can begin cutting, with minimal interaction with the saw.</li>

<li>If you’re a primary metal center, piping or oil and gas contractor looking to cut round tubes and pipe at a high production rate, the DoALL TDC-400CNC is an excellent choice. Nesting and auto indexing means you can load up multiple pieces of metal stock and cut at an increased speed.</li>

<li>The blade is sloped 7 degrees to cutting table, which enables better performance during cutting of profiles as well as full materials – this improves blade life. </li>

<li><strong>Operator Control Console</strong><br>

The operator control console is mounted at the front of the machine. Its placement insures the operator’s safety by keeping their hands clear of the sawband at band start</li>

<li><strong>Mitsubishi Touch Screen Panel</strong><br>

The colored touch screen control panel displays the cutting cycle indicator, blade tension warning, BRP (overfeed protection) function, band speed, band drive amp load, and a list of error messages allowing the operator to monitor all machine functions.</li>

<li><strong>Direct Driven Band Drive</strong><br>

Drive is comprised of an electric VFD controlled motor transferring power thru a gear reduction unit directly to the drive wheel eliminating belt slippage giving positive torque to the sawblade.</li>

<li><strong>Automatic Cycle</strong><br>

The Automatic Cycle function allows the operator the ability to write and save 20 programs containing 15 different lengths of parts eliminating the need to stop the cycle and reset for multiple part sizes of the same material saving production time.</li>

<li><strong>Automatic Overload Feed Protection</strong><br>

BRP function monitors the band drive motor amperage stopping head fall when the operator set parameter is reached signaling an overfeed condition or a dull saw band.</li>

<li><strong>Nesting Fixtures</strong><br>

Plug-n-play vertical hold-down clamp assemblies allow the operator to perform multiple pieces cutting increasing productivity.</li>

<li><strong>Hydraulic Clamping Vice</strong><br>

Full stroke hydraulic vices combined with a split front vice will minimize set up time and maximize clamping pressure eliminating material movement and tooth strippage.</li>

<li><strong>Floating Indexer</strong><br>

The vice carriage is guided with two rails and is hydraulically positioned by use of a DRO insuring accuracy and repeatability. The indexer “floats” allowing for lateral movement to clear crooked stock conditions so material is not dragged or scored during operations. The indexer is also capable of incremental indexing saving cycle time when in short part length operations increasing production.</li>

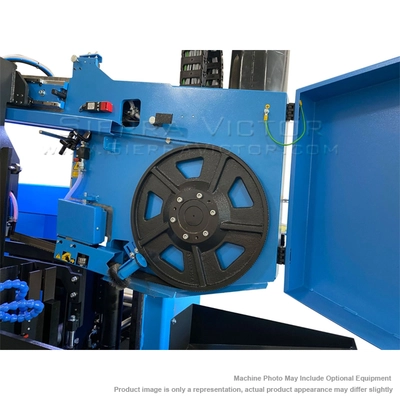

<li><strong>Hydraulic Band Tension</strong><br>

Eliminates the possibility of over/under tightening of the band for maximum cutting rates and saw band life.</li>

<li><strong>Saw Head Design</strong><br>

The saw head is mounted on linear rails which are mounted to two robust columns at a 7 degree cant. The 4 point head mounting system to the columns increases the stability of the saw head allowing for increased blade life.</li>

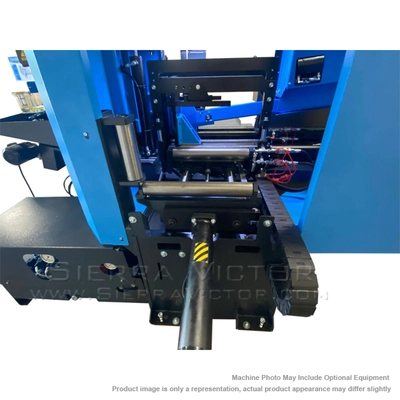

<li><strong>Band Brush</strong><br>

Driven Band brush removes the chips from the blade gullets which would prevent the blade from attaining maximum cutting rates and blade life.</li>

<li><strong>Warranty</strong><br>

One year parts and service subject to the terms and conditions listed on the last page.<br>

Optional ten year warranty is available (DoALL Cut Above 10 Year Warranty). </li>

</ul>

<p><strong> STANDARD EQUIPMENT:</strong>

</p>

<ul>

<li>Programable logic controller for all machine functions.</li>

<li>Automatic & semi-automatic cycle.</li>

<li>Mitsubishi controller.</li>

<li>Rapid head down approach.</li>

<li>Carbide faced saw guide inserts with lead in bearings.</li>

<li>Material Height Sensor.</li>

<li>Full stroke hydraulic vises.</li>

<li>Driven band cleaning brush.</li>

<li>Infinite band speed by variable frequency drive.</li>

<li>Automatic movable guide arm setting.</li>

<li>Cast steel band wheels.</li>

<li>Programable over feed protection.</li>

<li>Vertical hold downs.</li>

<li>Laser line generator.</li>

<li>Feed rate/feed force saw head control.</li>

<li>Mist band lubricator system.</li>

<li>Normal and incremental indexing.</li>

<li>Variable Vise Pressure.</li>

<li>LED work light.</li>

<li>7 degree cant design.</li>

<li>Saw blade guards.</li>

<li>Auger style chip conveyor.</li>

<li>Band door interlocks.</li>

<li>Operation and parts manuals on USB stick.</li>

<li>Recommended band speed chart.</li>

<li>One (1) complimentary DoALL Bi Metal saw blade.</li>

<li>Complimentary DoALL Cutting Fluids package.</li>

</ul>

<p><b>OPTIONAL ITEMS - CALL FOR PRICE:</b></p>

<ul>

<li>5 ft Medium-duty idler conveyor 16" between frames roller capacity 850 Ibs</li>

<li>10 ft Medium-duty idler conveyor 16" between frames roller capacity 850 Ibs</li>

<li>Chip pan with drain</li>

<li>Wear parts service kit - contains wear plates, guides, band brushes</li>

<li>Chip pan with drain</li>

<li>Handle for chip box</li>

<li>Magnetic wand chip remover</li>

<li>Additional USB stick of manuals</li>

<li>A Nationally Recognized Testing Laboratory (NRTL) is an independent third-part laboratory recognized by the United States Occupational Safety and Health Administration (OSHA) to test and certify products to applicable product safety standards</li>

<li>DoALL Cut Above 10 Year Warranty Annual Investment</li>

</ul>