<table width="520" cellspacing="0" cellpadding="0" border="1">

<tbody style="text-align: center;">

<tr>

<td class="TableText" valign="middle" bgcolor="#333333">

<div class="Title_white_bold" align="center">

<div align="center"><span style="color: rgb(255, 255, 255);"><strong>MODEL</strong></span>

</div>

</div>

</td>

<td class="Title_white_bold" width="257" valign="middle" bgcolor="#333333">

<div align="center"><span style="color: rgb(255, 255, 255);"><strong>TDC-1000CNC</strong></span>

</div>

</td>

</tr>

<tr>

<td class="TableText" valign="middle" bgcolor="#cccccc">

<div align="center">Cutting Capacity Rectangle

</div>

</td>

<td class="TableText" valign="middle">

<div align="center">38" x 40" (960x1000mm)

</div>

</td>

</tr>

<tr>

<td class="TableText" valign="middle" bgcolor="#cccccc">

<div align="center">Cutting Capacity Round Tube

</div>

</td>

<td class="TableText" valign="middle">

<div align="center">40" (1000mm)

</div>

</td>

</tr>

<tr>

<td class="TableText" valign="middle" bgcolor="#cccccc">

<div align="center">Cutting Capacity Round Solid

</div>

</td>

<td class="TableText" valign="middle">

<div align="center">21.7" (550mm)

</div>

</td>

</tr>

<tr>

<td class="TableText" valign="middle" bgcolor="#cccccc">

<div align="center">Maximum Bundle Capacity

</div>

</td>

<td class="TableText" valign="middle">

<div align="center">25.6 x 39.4" (650x1000mm)

</div>

</td>

</tr>

<tr>

<td class="TableText" valign="middle" bgcolor="#cccccc">

<div align="center">Minimum Bundle Capacity

</div>

</td>

<td class="TableText" valign="middle">

<div align="center">2" (50mm)

</div>

</td>

</tr>

<tr>

<td class="TableText" valign="middle" bgcolor="#cccccc">

<div align="center">Production Level

</div>

</td>

<td class="TableText" valign="middle">

<div align="center">Extreme

</div>

</td>

</tr>

<tr>

<td class="TableText" valign="middle" bgcolor="#cccccc">

<div align="center">Band Saw Blade Width

</div>

</td>

<td class="TableText" valign="middle">

<div align="center">2 x 0.063" (54x1.6mm)

</div>

</td>

</tr>

<tr>

<td class="TableText" valign="middle" bgcolor="#cccccc">

<div align="center">Maximum Blade Length

</div>

</td>

<td class="TableText" valign="middle">

<div align="center">351" (8920mm)

</div>

</td>

</tr>

<tr>

<td class="TableText" valign="middle" bgcolor="#cccccc">

<div align="center">Remnant Length Drop

</div>

</td>

<td class="TableText" valign="middle">

<div align="center">2" (50mm)

</div>

</td>

</tr>

<tr>

<td class="TableText" width="257" valign="middle" bgcolor="#cccccc">

<div align="center">Band Speed

</div>

</td>

<td class="TableText" valign="middle">

<div align="center">65-328 fpm (20-100mpm)

</div>

</td>

</tr>

<tr>

<td class="TableText" valign="middle" bgcolor="#cccccc">

<div align="center">Band Drive Motor

</div>

</td>

<td class="TableText" valign="middle">

<div align="center">10 hp (7.5kW)

</div>

</td>

</tr>

<tr>

<td class="TableText" valign="middle" bgcolor="#cccccc">

<div align="center">Hydraulic Pump

</div>

</td>

<td class="TableText" valign="middle">

<div align="center">5.4 hp (4kW)

</div>

</td>

</tr>

<tr>

<td class="TableText" valign="middle" bgcolor="#cccccc">

<div align="center">Coolant Pump

</div>

</td>

<td class="TableText" valign="middle">

<div align="center">0.2 hp (0.155kW)

</div>

</td>

</tr>

<tr>

<td class="TableText" valign="middle" bgcolor="#cccccc">

<div align="center">Coolant Tank Capacity

</div>

</td>

<td class="TableText" valign="middle">

<div align="center">53 gal (200 lit)

</div>

</td>

</tr>

<tr>

<td class="TableText" valign="middle" bgcolor="#cccccc">

<div align="center">Material Pass Line Height

</div>

</td>

<td class="TableText" valign="middle">

<div align="center">32" (815mm)

</div>

</td>

</tr>

<tr>

<td class="TableText" valign="middle" bgcolor="#cccccc">

<div align="center">Machine Weight

</div>

</td>

<td class="TableText" valign="middle">

<div align="center">13,316 lbs (6040kg)

</div>

</td>

</tr>

<tr>

<td class="TableText" valign="middle" bgcolor="#cccccc">

<div align="center">Dimensions W x L x H

</div>

</td>

<td class="TableText" valign="middle">

<div align="center">169 x 284 x 117" (5050x7200x2960mm)

</div>

</td>

</tr>

</tbody>

</table>

<p>Specifications are subject to change without notice.

</p>

<p>NOTE: Data is provided by the manufacturer.

</p>

<p><strong>WARRANTY: 1 YEAR</strong> – Parts

</p>

<ul>

<li> Machine Capacity: 38 x 40" (960x1000mm) </li>

<li> Round Tube: 40″ (1000mm) </li>

<li> Production Level: Extreme </li>

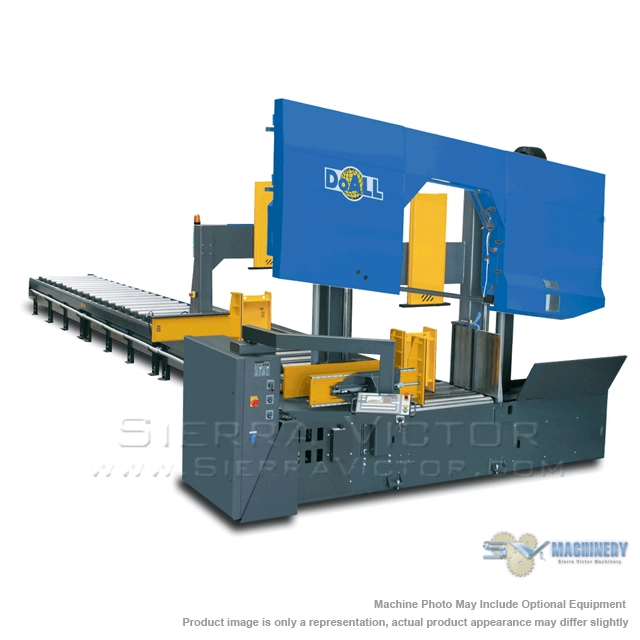

<li> The DoALL Olympia TDC-1000CNC is an automatic, dual column, CNC metal-cutting band saw specially designed to cut large tube and pipe. The TDC-1000CNC offers bundling to save time and money in high production environments like metal service centers. Also classified as a horizontal power specialty tube cut-off saw, the TDC-1000CNC ships with a work light, work height sensor and discharge chute. A large variety of optional accessories are available to customize the machine for specific sawing requirements. The TDC-1000CNC can be used for high-efficiency cutting on a wide range of structural shapes and configurations of tubing. </li>

<li><strong>Operator Control Console</strong><br>

The operator control console is mounted at the front of the machine. Its placement insures the operator’s safety by keeping their hands clear of the sawband at band start.</li>

<li><strong>Siemens Touch Screen Panel</strong><br>

The touchscreen workstation provides the operator with easy to access job programming along with constant monitoring of jobs while the machine is running in automatic. The work station also monitors and displays blade speed, head feed rate, and head and indexer position at all times. It automatically displays and stores any error messages for ease of troubleshooting eliminating long periods of downtime.</li>

<li><strong>Saw Head Design</strong><br>

The saw head is mounted on linear rails which are mounted to two robust columns at a 10 degree cant. The 4 point head mounting system to the columns increases stability of the saw head allowing for increased blade life.</li>

<li><strong>Direct Driven Band Drive</strong><br>

Drive is comprised of an electric VFD controlled motor transferring power thru a gear reduction unit directly to the drive wheel eliminating belt slippage giving positive torque to the sawblade.</li>

<li><strong>Retractable Shuttle Type Index Vice</strong><br>

Both index vice jaws retract when the vice is opened to accommodate the movement of crooked stock increasing accuracy and repeatability.</li>

<li><strong>Multiple Machine Cycles</strong><br>

The machine can be operated in either semi-automatic or automatic mode:<br>

In semi-automatic mode the material is placed manually by the operator or by use of the GTO function and clamped in place. The saw band is started and the cut is completed.<br>

In the automatic mode the operator programs the pieces to be cut in one of the 99 jobs, sets the material, and starts the cycle. The machine automatically cycles thru the parts as programmed making it a “hands free” operation</li>

<li><strong>Hydraulic Band Tension</strong><br>

Eliminates the possibility of over/under tightening of the band for maximum cutting rates and band life.</li>

<li><strong>Flood Coolant System</strong><br>

Supplies coolant to the blade evenly before and after the cut creating straighter cuts and allowing longer blade life due to coolant being supplied at the tooth tip.</li>

<li><strong>Modified Metered Feed System</strong><br>

The metered cutting feed rates are regulated by the use of a hydraulic throttle valve which is controlled by a servo motor which allows us to achieve a very precise feed rate. This rate is also monitored by the system using 2 programmable operator inputs ARP and RZP.<br>

ARP is an operator setting which allows the machine to regulate the feed rate depending on the resistance of the material or dulling of the saw blade decreasing the chance of out of square cuts.<br>

RZP is an operator setting allowing for the setting of optimal feed rates depending on the saw band position in the material. Rates can be automatically sped up or slowed down to decrease blade wear and increase productivity. </li>

</ul>

<p><strong> STANDARD EQUIPMENT:</strong>

</p>

<ul>

<li>Colored Siemens touch screen.</li>

<li>Automatic & semi-automatic cycle.</li>

<li>Chain driven chip conveyor.</li>

<li>Rapid head down approach.</li>

<li>Carbide faced saw guide inserts with lead in bearings.</li>

<li>Programmable material height sensor.</li>

<li>Full stroke hydraulic vises.</li>

<li>Electric driven band cleaning brush.</li>

<li>Infinite band speed by variable frequency drive.</li>

<li>Outboard clamping discharge vise.</li>

<li>Cast steel band wheels.</li>

<li>Programable modified metered feed system.</li>

<li>Vertical hold downs.</li>

<li>Hydraulic band tension.</li>

<li>Recirculating coolant system.</li>

<li>Mist band lubricator system.</li>

<li>Digitally displayed angle position with hydraulic lock.</li>

<li>Variable Vise Pressure.</li>

<li>Laser line generator.</li>

<li>LED work light.</li>

<li>10 degree cant design.</li>

<li>Saw blade guards.</li>

<li>Band door interlocks.</li>

<li>Operation and parts manuals on USB stick.</li>

<li>One (1) complimentary DoALL Bi-Metal saw blade.</li>

<li>Complimentary DoALL Cutting Fluids package</li>

</ul>

<p><b>OPTIONAL ITEMS - CALL FOR PRICE:</b></p>

<ul>

<li>6.6 ft (2000mm) Input or output conveyor with drip pan/gutter - cylinder width - 1142 lbs/ft capacity</li>

<li>5 ft Medium-duty idler conveyor between frames roller capacity 850 Ibs</li>

<li>10 ft Medium-duty idler conveyor between frames roller capacity 850 Ibs</li>

<li>Wear parts service kit - contains wear plates, guides, band brushes</li>

<li>Chip pan with drain</li>

<li>Handle for chip box</li>

<li>Magnetic wand chip remover</li>

<li>Additional USB stick of manuals</li>

<li>A Nationally Recognized Testing Laboratory (NRTL) is an independent third-part laboratory recognized by the United States Occupational Safety and Health Administration (OSHA) to test and certify products to applicable product safety standards</li>

<li>DoALL Cut Above 10 Year Warranty Annual Investment</li>

</ul>