<table width="520" cellspacing="0" cellpadding="0" border="1">

<tbody style="text-align: center;">

<tr class="Title_white" bgcolor="#333333">

<td class="TableText">

<div class="Title_white_bold" align="center">

<div align="center"><span style="color: rgb(255, 255, 255);"><strong>MODEL</strong></span>

</div>

</div>

</td>

<td class="TableText">

<div class="Title_white_bold" align="center">

<div align="center"><span style="color: rgb(255, 255, 255);"><strong>TF 470

</strong></span>

</div>

</div>

</td>

</tr>

<tr>

<td class="TableText" bgcolor="#cccccc">

<div align="center">Capacity

</div>

</td>

<td class="TableText">

<div align="center">26 ga. to 18 ga. galvanized mild steel

</div>

</td>

</tr>

<tr>

<td class="TableText" width="257" bgcolor="#cccccc">

<div align="center">Power

</div>

</td>

<td class="TableText" width="257">

<div align="center">220/3/60

</div>

</td>

</tr>

<tr>

<td class="TableText" width="257" bgcolor="#cccccc">

<div align="center">Pneumatics required

</div>

</td>

<td class="TableText">

<div align="center">100 psi with minimum of 200 l/min.

</div>

</td>

</tr>

<tr>

<td class="TableText" bgcolor="#cccccc">

<div align="center">Strip width

</div>

</td>

<td class="TableText">

<div align="center">5.394”

</div>

</td>

</tr>

<tr>

<td class="TableText" bgcolor="#cccccc">

<div align="center">Programmable feed speed range

</div>

</td>

<td class="TableText">

<div align="center">approx. 0-100 FPM.

</div>

</td>

</tr>

<tr>

<td class="TableText" bgcolor="#cccccc">

<div align="center">Weight

</div>

</td>

<td class="TableText">

<div align="center">4,630 lbs

</div>

</td>

</tr>

<tr>

<td class="TableText" bgcolor="#cccccc">

<div align="center">Foot print

</div>

</td>

<td class="TableText">

<div align="center">154” x 140” x 70”high

</div>

</td>

</tr>

</tbody>

</table>

<p>Specifications are subject to change without notice.

</p>

<p>NOTE: Data is provided by the manufacturer.

</p>

<p><strong>WARRANTY: 1 YEAR</strong>

</p>

<ul>

<li><strong>TAKE IT TO THE JOB SITE! DON’T SHIP AIR!</strong> You don’t want to ship already formed duct if possible, right. The Bravo Spiral Duct Former is compact, strong and mobile. It is easy to take from one jobsite to another. Producing on-site eliminates the need to ship “air”, it also eliminates the hand cutting to length. Program any length up to 10ft. It will automatically and silently cut (slit) the duct to length.</li>

<li>2200 lb capacity payoff reel.</li>

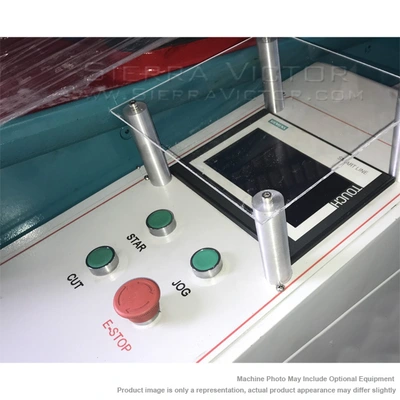

<li>Control Panel with easy to use interface…<u>programmable in English – Spanish</u></li>

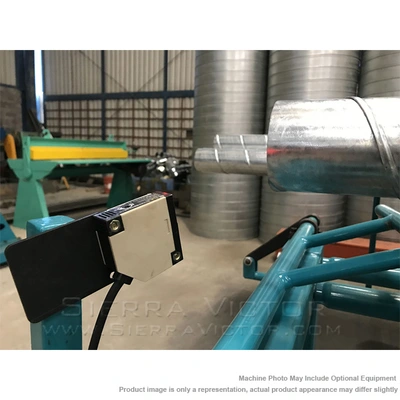

<li>Length control by Infrared Sensor Switch</li>

<li><u>Flying Slitter Cut-off</u> System….smooth and quiet.</li>

<li><u>Plasma Cutting System</u>… special for heavy gauges.</li>

<li>10ft Run Out Table with Automatic Dumping</li>

<li>Receiver table for duct sections dumped from the Run Out Table</li>

<li><u>Beading Attachment</u> optional (for stiffening lighter gauges)</li>

<li>Two roll formers cassettes to enable duct forming from 26 gauge to 18 gauge galvanized.</li>

<li><u>Hard Tool Molds, from 4” to 70</u>” (pairs diam)</li>

<li>Forms mild <u>steel, aluminum and stainless</u></li>

<li>Meets SMACNA Standards</li>

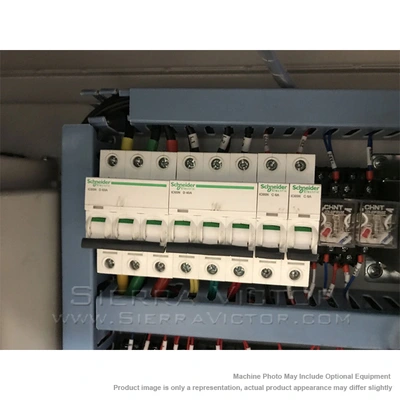

<li>Internationally recognized and available components to include but not limited to:</li>

<li>Schneider Electrics</li>

<li>Siemens PLC and Touchscreen</li>

<li>Delta Inverter</li>

<li>NSK Bearings</li>

<li>Hypertherm Plasma Unit</li>

<li>Expected Performance, based on 10ft sections. </li>

<li>– 0.5 mm (0.020’’) thickness – 100 mm (4”) diameter – 120 Ducts/hour<br>

– 0.7 mm (0.028’’) thickness – 500 mm (20”) diameter – 45 Ducts/hour<br>

– 0.9 mm (0.035’’) thickness – 1250 mm (50”) diameter – 15 Ducts/hour<br>

</li>

</ul>