<table width="520" cellspacing="0" cellpadding="0" border="1">

<tbody style="text-align: center;">

<tr>

<td class="TableText" width="257" bgcolor="#cccccc">

<div align="center">Max. Drill Capacity

</div>

</td>

<td class="TableText" width="257">

<div align="center">2-1/2" (No.45 steel) & 2-7/8" <br>

(HT200 cast iron)

</div>

</td>

</tr>

<tr>

<td class="TableText" bgcolor="#cccccc">

<div align="center">Max. Tapping Capacity

</div>

</td>

<td class="TableText">

<p>1-3/4" (No.45 steel) & <br>2" (HT200 cast iron)

</p>

</td>

</tr>

<tr>

<td class="TableText" width="257" bgcolor="#cccccc">

<div align="center">Distance from Spindle to Column Center

</div>

</td>

<td class="TableText" width="257">

<div align="center">13-3/4" to 63"

</div>

</td>

</tr>

<tr>

<td class="TableText" width="257" bgcolor="#cccccc">

<div align="center">Diameter of Column

</div>

</td>

<td class="TableText" width="257">

<div align="center">13.7"

</div>

</td>

</tr>

<tr>

<td class="TableText" width="257" bgcolor="#cccccc">

<div align="center">Spindle Taper

</div>

</td>

<td class="TableText" width="257">

<div align="center">MT5

</div>

</td>

</tr>

<tr>

<td class="TableText" width="257" bgcolor="#cccccc">

<div align="center">Spindle Travel

</div>

</td>

<td class="TableText" width="257">

<div align="center">12-3/8"

</div>

</td>

</tr>

<tr>

<td class="TableText" width="257" bgcolor="#cccccc">

<div align="center">Spindle Speed Range

</div>

</td>

<td class="TableText" width="257">

<div align="center">38 to 2000 rpm (variable)

</div>

</td>

</tr>

<tr>

<td class="TableText" width="257" bgcolor="#cccccc">

<div align="center">Range of Spindle Feeds

</div>

</td>

<td class="TableText" width="257">

<div align="center">.0024" to .0394" in/rev

</div>

</td>

</tr>

<tr>

<td class="TableText" width="257" bgcolor="#cccccc">

<div align="center">Spindle Feeds

</div>

</td>

<td class="TableText" width="257">

<div align="center">Inverter Driven

</div>

</td>

</tr>

<tr>

<td class="TableText" width="257" bgcolor="#cccccc">

<div align="center">Distance Between Spindle Nose and Base

</div>

</td>

<td class="TableText" width="257">

<div align="center">13-3/4" to 49-1/4"

</div>

</td>

</tr>

<tr>

<td class="TableText" width="257" bgcolor="#cccccc">

<div align="center">Table Size

</div>

</td>

<td class="TableText" width="257">

<div align="center">24.8" x 19.6" x 19.6"

</div>

</td>

</tr>

<tr>

<td class="TableText" width="257" bgcolor="#cccccc">

<div align="center">Base Size

</div>

</td>

<td class="TableText" width="257">

<div align="center">94.4" x 39.3" x 7.8

</div>

</td>

</tr>

<tr>

<td class="TableText" width="257" bgcolor="#cccccc">

<div align="center">Overall Size

</div>

</td>

<td class="TableText" width="257">

<div align="center">98” x 40”~96” x 103”~112” <br>

Accounting for Beam Movements

</div>

</td>

</tr>

<tr>

<td class="TableText" bgcolor="#cccccc">

<div align="center">Travel Speed

</div>

</td>

<td class="TableText">

<div align="center">47.2 in/min. (arm movement)

</div>

</td>

</tr>

<tr>

<td class="TableText" width="257" bgcolor="#cccccc">

<div align="center">Motor

</div>

</td>

<td class="TableText" width="257">5.25 HP

</td>

</tr>

<tr>

<td class="TableText" width="257" bgcolor="#cccccc">

<div align="center">Power

</div>

</td>

<td class="TableText" width="257">

<div align="center">220V, 3-phase

</div>

</td>

</tr>

<tr>

<td class="TableText" bgcolor="#cccccc">

<div align="center">Shipping Dimensions

</div>

</td>

<td class="TableText">

<div align="center">102.375” x 44” x 100”

</div>

</td>

</tr>

<tr>

<td class="TableText" bgcolor="#cccccc">

<div align="center">Shipping Weight

</div>

</td>

<td class="TableText">

<div align="center">9,460 lbs.

</div>

</td>

</tr>

</tbody>

</table>

<p>Specifications are subject to change without notice.

</p>

<p>NOTE: Data is provided by the manufacturer.

</p>

<p><strong>WARRANTY: 1 YEAR</strong> – Parts

</p>

<ul>

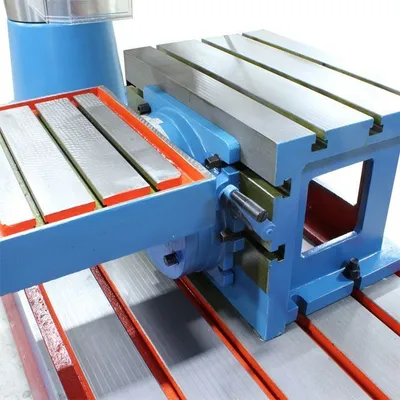

<li> RD-1600H-VS Variable Speed Radial Drill is a step above other conventional radial drills. It is suitable for medium and small parts in drilling, spot facing, counter-boring and taping etc. It is really an idea machine suitable for single work piece machining and batch production in the machining workshop, maintenance workshop and tool production workshop. </li>

<li>Inverter driven, variable speed</li>

<li>38 to 2000 rpm</li>

<li>Heavy duty, oversized spindle</li>

<li>Integrated coolant system with easy to reach switch</li>

<li>Hydraulic clamping for column, arm and spindle box</li>

<li>Power down feed </li>

</ul>