<table width="520" cellspacing="0" cellpadding="0" border="1">

<tbody style="text-align: center;">

<tr>

<td colspan="2" class="TableText" valign="middle" bgcolor="#333333">

<div class="Title_white_bold" align="center">

<div align="center"><span style="color: rgb(255, 255, 255);"><strong>MODEL</strong></span>

</div>

</div>

</td>

<td class="Title_white_bold" width="257" valign="middle" bgcolor="#333333">

<div align="center"><span style="color: rgb(255, 255, 255);"><strong>DC-800NC</strong></span>

</div>

</td>

</tr>

<tr>

<td rowspan="2" class="TableText" width="116" valign="middle" bgcolor="#cccccc">

<div align="center">Cutting Capacity

</div>

</td>

<td class="TableText" width="139" valign="middle" bgcolor="#cccccc">

<div align="center">Round:

</div>

</td>

<td class="TableText" valign="middle">

<div align="center">31.5" (800mm)

</div>

</td>

</tr>

<tr>

<td class="TableText" valign="middle" bgcolor="#cccccc">

<div align="center">Rectangle: (W x H)

</div>

</td>

<td class="TableText" valign="middle">

<div align="center">31-1/2 x 39-1/2" (800x1000mm)

</div>

</td>

</tr>

<tr>

<td colspan="2" class="TableText" valign="middle" bgcolor="#cccccc">

<div align="center">Saw Blade - Width x Length

</div>

</td>

<td class="TableText" valign="middle">

<div align="center">2.625" x 347"

</div>

</td>

</tr>

<tr>

<td rowspan="3" class="TableText" valign="middle" bgcolor="#cccccc">

<div align="center">Band Drive

</div>

</td>

<td class="TableText" valign="middle" bgcolor="#cccccc">

<div align="center">Motor HP

</div>

</td>

<td class="TableText" valign="middle">

<div align="center">15 HP

</div>

</td>

</tr>

<tr>

<td class="TableText" valign="middle" bgcolor="#cccccc">

<div align="center">Band Speed

</div>

</td>

<td class="TableText" valign="middle">

<div align="center">52-275 fpm

</div>

</td>

</tr>

<tr>

<td class="TableText" valign="middle" bgcolor="#cccccc">

<div align="center">Band Tension

</div>

</td>

<td class="TableText" valign="middle">

<div align="center">Hydraulic

</div>

</td>

</tr>

<tr>

<td rowspan="2" class="TableText" valign="middle" bgcolor="#cccccc">

<div align="center">Hydraulic System

</div>

</td>

<td class="TableText" valign="middle" bgcolor="#cccccc">

<div align="center">Motor HP

</div>

</td>

<td class="TableText" valign="middle">

<div align="center">3 HP

</div>

</td>

</tr>

<tr>

<td class="TableText" valign="middle" bgcolor="#cccccc">

<div align="center">Reservoir Size

</div>

</td>

<td class="TableText" valign="middle">

<div align="center">34 Gallon

</div>

</td>

</tr>

<tr>

<td rowspan="3" class="TableText" valign="middle" bgcolor="#cccccc">

<div align="center">Coolant System

</div>

</td>

<td class="TableText" valign="middle" bgcolor="#cccccc">

<div align="center">Coolant System

</div>

</td>

<td class="TableText" valign="middle">

<div align="center">Flood coolant

</div>

</td>

</tr>

<tr>

<td class="TableText" valign="middle" bgcolor="#cccccc">

<div align="center">Motor HP

</div>

</td>

<td class="TableText" valign="middle">

<div align="center">1/4 HP

</div>

</td>

</tr>

<tr>

<td class="TableText" valign="middle" bgcolor="#cccccc">

<div align="center">Reservoir Size

</div>

</td>

<td class="TableText" valign="middle">

<div align="center">63 Gallon

</div>

</td>

</tr>

<tr>

<td rowspan="3" class="TableText" valign="middle" bgcolor="#cccccc">

<div align="center">Indexer

</div>

</td>

<td class="TableText" valign="middle" bgcolor="#cccccc">

<div align="center">Length per Stroke

</div>

</td>

<td class="TableText" valign="middle">

<div align="center">15.75"

</div>

</td>

</tr>

<tr>

<td class="TableText" valign="middle" bgcolor="#cccccc">

<div align="center">Maximum Index <br>

Strokes Length

</div>

</td>

<td class="TableText" valign="middle">

<div align="center">236"

</div>

</td>

</tr>

<tr>

<td class="TableText" valign="middle" bgcolor="#cccccc">

<div align="center">Remnant Length

</div>

</td>

<td class="TableText" valign="middle">

<div align="center">9" (non bundle)

</div>

</td>

</tr>

<tr>

<td colspan="2" class="TableText" valign="middle" bgcolor="#cccccc">

<div align="center">Voltage Requirement

</div>

</td>

<td class="TableText" valign="middle">

<div align="center">230V-60Hz-3ph, Wye configuration

</div>

</td>

</tr>

<tr>

<td colspan="2" class="TableText" valign="middle" bgcolor="#cccccc">

<div align="center">Total Amp Draw (FLA)

</div>

</td>

<td class="TableText" valign="middle">

<div align="center">61 Amps

</div>

</td>

</tr>

<tr>

<td colspan="2" class="TableText" valign="middle" bgcolor="#cccccc">

<div align="center">Floor Space Dimensions W x L X H

</div>

</td>

<td class="TableText" valign="middle">

<div align="center">172" x 94" x 108"

</div>

</td>

</tr>

<tr>

<td colspan="2" class="TableText" valign="middle" bgcolor="#cccccc">

<div align="center">Material Pass Height

</div>

</td>

<td class="TableText" valign="middle">

<div align="center">36"

</div>

</td>

</tr>

<tr>

<td colspan="2" class="TableText" valign="middle" bgcolor="#cccccc">

<div align="center">Machine Weight

</div>

</td>

<td class="TableText" valign="middle">

<div align="center">25,350 lbs.

</div>

</td>

</tr>

</tbody>

</table>

<p>Specifications are subject to change without notice.

</p>

<p>NOTE: Data is provided by the manufacturer.

</p>

<p><strong>WARRANTY: 1 YEAR</strong> – Parts

</p>

<ul>

<li> Machine Capacity: w 39.5" x h 31.5" (1000mm x 800mm) </li>

<li> Production Level: High </li>

<li><strong>Standard Features: Touch Screen Control, Nesting Fixtures and Retractable Shuttle Type Index Vise</strong></li>

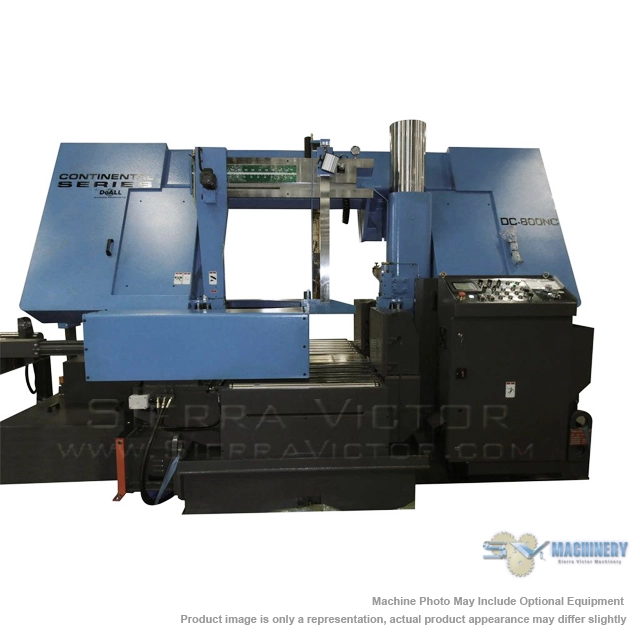

<li> The DC-800NC Continental Series™ high production horizontal band saw by DoALL is designed for cutting a wide range of materials in a fully-automated capacity. </li>

<li> If you are a primary metal supplier, foundry or cutting large parts for heavy-duty applications, the DC-800NC will provide you with both robust build quality and improved production. </li>

<li> The DC-800NC comes with digital touch screen controls, which operate the fully hydraulic accessories. </li>

<li><strong>Touch Screen Control: </strong>Easy operator input. 20 Job storage with batching capabilities. Control is multi-lingual for today's workforce. Will display error message when incorrect entry is made. Easy switching between imperial or metric units.<br>

</li>

<li><strong>High-Efficiency Transmission: </strong>High-efficiency worm gear box built to decrease wear and transmit full torque to the saw blade. Double wide “V” belt to avoid slipping, transmitting full motor power to the transmission.<br>

</li>

<li><strong>Hydraulic Chip Conveyor: </strong>Adjustable speed auger style conveyor allows for coolant drain from chips before extraction.<br>

</li>

<li><strong>Coolant Thru Carbide Faced Saw Guide Inserts: </strong>Supplies coolant to the blade evenly before and after the cut creating straighter cuts and allowing longer blade life due to coolant being supplied at the tooth tip.<br>

</li>

<li><strong>Efficiently Designed Hydraulic System: </strong>Engineered low-pressure system allows for a smoother and quieter operation which aids in longer component life and easy accessibility for maintenance.</li>

<li><strong>Band Wheels: </strong>30 Degree lay-back head design minimizes band twist which causes band fatigue and also allows a smaller foot print. Flange cast steel wheels insure band tracking to prevent tooth set lost.</li>

<li><strong>Underslung Indexer System: </strong>Reduces friction when indexing heavier or rough surface material by the use of rollers allowing for smoother material movements.</li>

<li><strong>Movable Saw Guide Arm: </strong>An electrical driven movable guide arm with a hydraulic lock system aids the operator in the placement of the arm close to the cut minimizes blade deflection.</li>

<li><strong>Hydraulic Blade Tension: </strong>Eliminates possible error of over/under-tightening the band for maximum cutting rates and band life.<br>

</li>

<li><strong>Back-up Bearing/Inserts</strong>: Supports the back of the saw band allowing the creation of band preload which aids in reducing vibration while cutting and increasing blade life.</li>

<li><strong>Retractable Shuttle Type Index Vise</strong>: Both jaws retract when vise is opened to accommodate the movement of crooked stock increasing accuracy and repeatability.<br>

</li>

<li><strong>Magnetic Scale for Indexer: </strong>The scale which creates indexing accuracy is protected from dirt and oil build up insuring its long life.<br>

</li>

<li><strong>Nesting Fixtures: </strong>Plug-n-play vertical hold-down clamp assemblies allow the operator to perform multiple-piece cutting to increase productivity.</li>

<li><strong>Warranty: </strong>One-year parts and service subject to the terms and conditions. 10-year manufacturer’s warranty available (Cut Above Lifetime Warranty). </li>

</ul>

<p><strong>STANDARD EQUIPMENT:</strong>

</p>

<ul>

<li>Programmable Logic Controller for all machine functions</li>

<li>Feed rate/feed force saw head control</li>

<li>Infinite band speed controlled variable frequency drive</li>

<li>Hydraulic retractable shuttle vice material indexer on chrome rails</li>

<li>Rapid and creep speed index vice control</li>

<li>Full stroke vices with moveable outboard front vise</li>

<li>Variable vice pressure control</li>

<li>Vertical hydraulic cylinders with hold down fixtures</li>

<li>Hydraulic set, zero clearance, coolant through,</li>

<li>carbide faced saw guide inserts with lead in rollers</li>

<li>Adjustable power driven band cleaning brushes with coolant flush line attached</li>

<li>Halogen work light</li>

<li>Electric motor driven movable saw guide arm</li>

<li>Blade shock proof device</li>

<li>Flushing hose for machine wash down and auxiliary coolant nozzles</li>

<li>Hydraulic band tension</li>

<li>Hydraulic adjustable speed auger design chip conveyor</li>

<li>One shot column lubricator</li>

<li>Saw band break/stall motion detector shut off switch</li>

<li>Band door interlocks</li>

<li>Operation and parts manuals on USB stick</li>

<li>One 6.5 ft. (2M) idler input conveyor</li>

<li>Maintenance tool kit</li>

<li>Complimentary DoALL Cutting Fluids package</li>

<li>One (1) complimentary DoALL Bi Metal saw blade</li>

</ul>

<p><b>OPTIONAL ITEMS - CALL FOR PRICE:</b></p>

<ul>

<li>10 ft. idler conveyor</li>

<li>5 ft. idler conveyor with filler plates</li>

<li>Out of square detection</li>

<li>Additional USB stick of manuals</li>

<li>Laser line</li>

<li>A Nationally Recognized Testing Laboratory (NRTL) is an independent third-part laboratory recognized by the United States Occupational Safety and Health Administration (OSHA) to test and certify products to applicable product safety standards.</li>

<li>DoALL Cut Above 10 Year Warranty Annual Investment</li>

</ul>