<table width="520" cellspacing="0" cellpadding="0" border="1">

<tbody style="text-align: center;">

<tr>

<td class="TableText" bgcolor="#cccccc">

<div align="center">Country of Manufacture

</div>

</td>

<td class="TableText">

<div align="center">United States

</div>

</td>

</tr>

<tr>

<td class="TableText" width="257" bgcolor="#cccccc">

<div align="center">Motor Hp

</div>

</td>

<td class="TableText" width="257">

<div align="center">3

</div>

</td>

</tr>

<tr>

<td class="TableText" width="257" bgcolor="#cccccc">

<div align="center">Speed

</div>

</td>

<td class="TableText" width="257">

<div align="center">0 - 1000 beats / min (Variable)

</div>

</td>

</tr>

<tr>

<td class="TableText" bgcolor="#cccccc">

<div align="center">Mild Steel Capacity

</div>

</td>

<td class="TableText">

<div align="center">14 ga.

</div>

</td>

</tr>

<tr>

<td class="TableText" width="257" bgcolor="#cccccc">

<div align="center">Tooling Height Adjustment

</div>

</td>

<td class="TableText" width="257">

<div align="center">2"

</div>

</td>

</tr>

<tr>

<td class="TableText" bgcolor="#cccccc">

<div align="center">Throat Depth

</div>

</td>

<td class="TableText">

<div align="center">28"

</div>

</td>

</tr>

<tr>

<td class="TableText" width="257" bgcolor="#cccccc">

<div align="center">Working Height

</div>

</td>

<td class="TableText" width="257">

<div align="center">62.5"

</div>

</td>

</tr>

<tr>

<td class="TableText" bgcolor="#cccccc">

<div align="center">Aluminum Capacity

</div>

</td>

<td class="TableText">

<div align="center">10 ga

</div>

</td>

</tr>

<tr>

<td class="TableText" bgcolor="#cccccc">

<div align="center">Length Of Stroke Adj

</div>

</td>

<td class="TableText">

<div align="center">3 Fixed Lengths: 1/4", 1/2", 3/4"

</div>

</td>

</tr>

<tr>

<td class="TableText" bgcolor="#cccccc">

<div align="center">Power

</div>

</td>

<td class="TableText">

<div align="center">220V / 1-phase

</div>

</td>

</tr>

<tr>

<td class="TableText" bgcolor="#cccccc">

<div align="center">Shipping Dimensions

</div>

</td>

<td class="TableText">

<div align="center">60" x 50" x 98"

</div>

</td>

</tr>

<tr>

<td class="TableText" bgcolor="#cccccc">

<div align="center">Shipping Weight

</div>

</td>

<td class="TableText">

<div align="center">2,000 lbs.

</div>

</td>

</tr>

<tr>

<td class="TableText" bgcolor="#cccccc">

<div align="center">*Optional Tooling

</div>

</td>

<td class="TableText">

<div align="center">

<p>Some applications may require optional tooling. Please contact Sierra Victor Industries 386-304-3720 with specific application details.

</p>

</div>

</td>

</tr>

<tr>

<td class="TableText" bgcolor="#cccccc">

<div align="center">Special Notes

</div>

</td>

<td class="TableText">

<div align="center">

<p>*Does Not Include Tooling, Uses Same Tooling as MH-19. Please consult Sierra Victor Industries 386-304-3720 for proper tooling.

</p>

</div>

</td>

</tr>

</tbody>

</table>

<p>Specifications are subject to change without notice.

</p>

<p>NOTE: Data is provided by the manufacturer.

</p>

<p><strong>WARRANTY: 1 YEAR</strong> – Parts

</p>

<ul>

<li>The PH-28HD-VS power hammer can <strong>hit harder and move metal faster</strong> than most hammers its size. This<strong> USA-made</strong> machine lets you shape multiple sheets at once, then planish them out.</li>

<li><strong>28” throat</strong> with deep cutout designed for <strong>fenders</strong>.</li>

<li>Large <strong>14 gauge</strong> mild steel capacity.</li>

<li>Variable speed from <strong>0 to 1,000 beats</strong> per minute.</li>

<li><strong>3 hp</strong> motor runs on <strong>220-volt single</strong>-phase power.</li>

<li>Developed over <strong>20 years of research</strong> to find what’s most important to metal shapers.</li>

<li>Hits up to <strong>75% harder</strong> than its predecessor, the MH-19.</li>

<li>Incorporates Dupont linkage (also used on our massive MH-37HD) to shape heavier gauges of steel.</li>

<li><strong>Quick-release design</strong> lets you get the tooling out of the way to add or remove your panel.</li>

<li>Switch between <strong>3 fixed stroke settings</strong> on the fly: ¼”, ½”, ¾”.</li>

<li>Adjust the lower ram up or down via a large acme thread, so <strong>you won’t need to shim if different tool thicknesses are required</strong>.</li>

<li>Simple, proven mechanism uses easily replaceable, off-the-shelf die springs.</li>

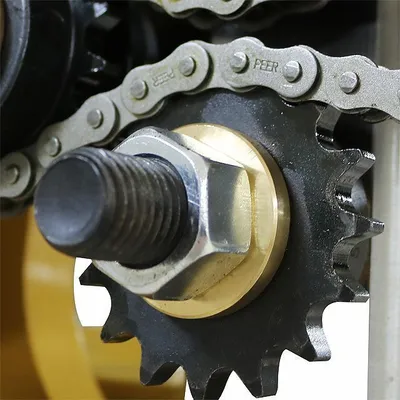

<li><strong>Floating chain and sprocket setup</strong> eliminates the leather strap commonly found on legacy hammers.</li>

<li>You can add an optional planishing hammer attachment to the side of this power hammer.</li>

<li>Rigid <strong>1” plate steel frame</strong> ensures high-quality, controllable shaping force and won’t buckle under the heavy hits.</li>

<li><strong>Portable pedestal</strong> raises the working height and allows better visibility of the hit mark.</li>

<li>Covered by a <strong>1-year parts warranty</strong>.</li>

<li>Our team of experienced metal shapers is here to provide <strong>lifetime technical support by phone</strong>.</li>

<li> <strong>Recommended for:</strong> Automotive shops that need to shape metal quickly and often work on fenders. </li>

</ul>