<table width="520" cellspacing="0" cellpadding="0" border="1">

<tbody style="text-align: center;">

<tr>

<td colspan="2" class="TableText1" bgcolor="#CCCCCC">

<div align="center">Diameter of column (in.)

</div>

</td>

<td class="TableText1" width="257">

<div align="center">21.65

</div>

</td>

</tr>

<tr>

<td colspan="2" class="TableText1" bgcolor="#CCCCCC">

<div align="center">Distance from column<br>

surface to spindle center, max. (in.)

</div>

</td>

<td class="TableText1">

<div align="center">98.42

</div>

</td>

</tr>

<tr>

<td colspan="2" class="TableText1" bgcolor="#CCCCCC">

<div align="center">Distance from column <br>

surface to spindle center, min. (in.)

</div>

</td>

<td class="TableText1">

<div align="center">—

</div>

</td>

</tr>

<tr>

<td colspan="2" class="TableText1" bgcolor="#CCCCCC">

<div align="center">Travel of spindle head (in.)

</div>

</td>

<td class="TableText1">

<div align="center">78.74

</div>

</td>

</tr>

<tr>

<td colspan="2" class="TableText1" bgcolor="#CCCCCC">

<div align="center">Distance from base <br>

surface to spindle end, max. (in.)

</div>

</td>

<td class="TableText1">

<div align="center">78.74

</div>

</td>

</tr>

<tr>

<td colspan="2" class="TableText1" bgcolor="#CCCCCC">

<div align="center">Distance from base <br>

surface to spindle end, min. (in.)

</div>

</td>

<td class="TableText1">

<div align="center">21.65

</div>

</td>

</tr>

<tr>

<td colspan="2" class="TableText1" bgcolor="#CCCCCC">

<div align="center">Elevating height of arm (in.)

</div>

</td>

<td class="TableText1">

<div align="center">39.37

</div>

</td>

</tr>

<tr>

<td colspan="2" class="TableText1" bgcolor="#CCCCCC">

<div align="center">Effective area of table (in.)

</div>

</td>

<td class="TableText1">

<div align="center">39.37 x 31.49 x 22.04

</div>

</td>

</tr>

<tr>

<td colspan="2" class="TableText1" bgcolor="#CCCCCC">

<div align="center">Dimensions of base (in.)

</div>

</td>

<td class="TableText1">

<div align="center">138.58 x 55.12 x 12.60

</div>

</td>

</tr>

<tr>

<td colspan="2" class="TableText1" bgcolor="#CCCCCC">

<div align="center">Taper hole in spindle

</div>

</td>

<td class="TableText1">

<div align="center">MT # 6

</div>

</td>

</tr>

<tr>

<td colspan="2" class="TableText1" bgcolor="#CCCCCC">

<div align="center">Stoke of spindle (in.)

</div>

</td>

<td class="TableText1">

<div align="center">17.72

</div>

</td>

</tr>

<tr>

<td colspan="2" class="TableText1" bgcolor="#CCCCCC">

<div align="center">R.P.M. of spindle (rpm range x steps)

</div>

</td>

<td class="TableText1">

<div align="center">16-1,250 x 16 steps

</div>

</td>

</tr>

<tr>

<td colspan="2" class="TableText1" bgcolor="#CCCCCC">

<div align="center">Feed of spindle (Rev. x steps)

</div>

</td>

<td class="TableText1">

<div align="center">0.0016-0.126 in. x 16 steps

</div>

</td>

</tr>

<tr>

<td colspan="2" class="TableText1" bgcolor="#CCCCCC">

<div align="center">Main motor (HP)

</div>

</td>

<td class="TableText1">

<div align="center">10 HP

</div>

</td>

</tr>

<tr>

<td colspan="2" class="TableText1" bgcolor="#CCCCCC">

<div align="center">Elevating motor (HP)

</div>

</td>

<td class="TableText1">

<div align="center">5 HP

</div>

</td>

</tr>

<tr>

<td colspan="2" class="TableText1" bgcolor="#CCCCCC">

<div align="center">Coolant Equipment (HP)

</div>

</td>

<td class="TableText1">

<div align="center">0.25 HP

</div>

</td>

</tr>

<tr>

<td colspan="2" class="TableText1" bgcolor="#CCCCCC">

<div align="center">Machine height from floor, max. (ft.)

</div>

</td>

<td class="TableText1">

<div align="center">13.09

</div>

</td>

</tr>

<tr>

<td colspan="2" class="TableText1" bgcolor="#CCCCCC">

<div align="center">Base + Column Height (ft.)

</div>

</td>

<td class="TableText1">

<div align="center">12.63

</div>

</td>

</tr>

<tr>

<td colspan="2" class="TableText1" bgcolor="#CCCCCC">

<div align="center">Shipping Dimensions (L x W x H) (ft.)

</div>

</td>

<td class="TableText1">

<div align="center">13.12 x 5.25 x 12.63

</div>

</td>

</tr>

<tr>

<td colspan="2" class="TableText1" bgcolor="#CCCCCC">

<div align="center">Net Weight (lbs.)

</div>

</td>

<td class="TableText1">

<div align="center">24,200

</div>

</td>

</tr>

<tr>

<td colspan="2" class="TableText1" bgcolor="#CCCCCC">

<div align="center">Shipping Weight (lbs.)

</div>

</td>

<td class="TableText1">

<div align="center">27,500

</div>

</td>

</tr>

<tr>

<td rowspan="2" class="TableText1" width="100" bgcolor="#CCCCCC">

<div align="center">Cast Iron

</div>

</td>

<td class="TableText1" width="155" bgcolor="#CCCCCC">

<div align="center">Drilling (in.)

</div>

</td>

<td class="TableText1">

<div align="center">3.15

</div>

</td>

</tr>

<tr>

<td class="TableText1" bgcolor="#CCCCCC">

<div align="center">Capacity Tapping (in.)

</div>

</td>

<td class="TableText1">

<div align="center">3.94

</div>

</td>

</tr>

<tr>

<td rowspan="2" class="TableText1" bgcolor="#CCCCCC">

<div align="center">Steel

</div>

</td>

<td class="TableText1" bgcolor="#CCCCCC">

<div align="center">Drilling (in.)

</div>

</td>

<td class="TableText1">

<div align="center">2.56

</div>

</td>

</tr>

<tr>

<td class="TableText1" bgcolor="#CCCCCC">

<div align="center">Capacity Tapping (in.)

</div>

</td>

<td class="TableText1">

<div align="center">2.95

</div>

</td>

</tr>

<tr>

<td rowspan="2" class="TableText1" bgcolor="#CCCCCC">

<div align="center">Total Power Consumption

</div>

</td>

<td class="TableText1" bgcolor="#CCCCCC">

<div align="center">220V

</div>

</td>

<td class="TableText1">

<div align="center">18KVA/50 amps

</div>

</td>

</tr>

<tr>

<td class="TableText1" bgcolor="#CCCCCC">

<div align="center">440V

</div>

</td>

<td class="TableText1">

<div align="center">18KVA/25 amps

</div>

</td>

</tr>

</tbody>

</table>

<p>Specifications are subject to change without notice.

</p>

<p>NOTE: Data is provided by the manufacturer.

</p>

<p><strong>WARRANTY: 1 YEAR</strong> – Parts

</p>

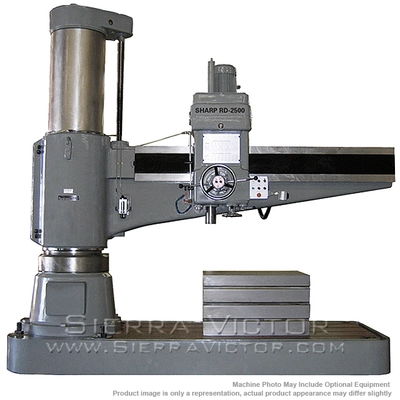

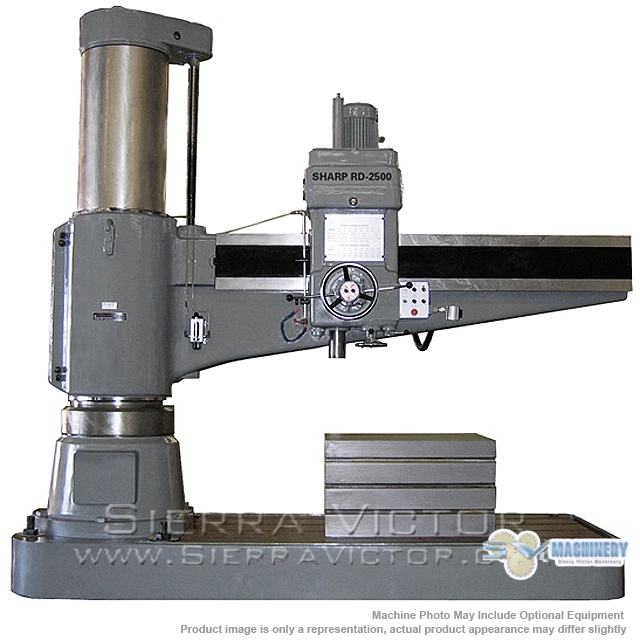

<ul>

<li>This is a high performance machine ideal for drilling, tapping , boring, reaming, lapping, screwing, counter boring, spot facing, and much more, on materials such as cast iron and steel.</li>

<li>22” column diameter</li>

<li>MT #6 spindle, 10 HP motor</li>

<li>98” column to spindle center</li>

<li>Drilling: 3.9” cast iron, 3.1” steel</li>

<li>Boring: 8.2” cast iron, 6.5” steel</li>

<li>Double tube column design for extra rigidity</li>

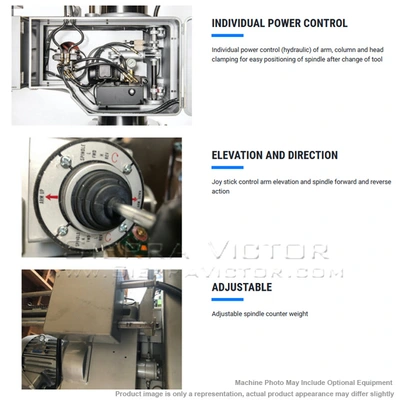

<li>Arm elevation controlled by hydraulic motor</li>

<li>Built-in automatic tool ejector</li>

<li>Safety device prevents arm from dropping even when bronze nut is worn out</li>

<li>Auto reverse tapping function</li>

<li>T-slots and drain channels on box table</li>

</ul>

<p><strong>STANDARD EQUIPMENT:</strong>

</p>

<ul>

<li>Box table</li>

<li>Coolant system</li>

<li>Work light</li>

<li>220V or 440V</li>

</ul>

<p><b>OPTINAL ITEMS - Call for price:</b></p>

<ul>

<li>Tilting table</li>

</ul>