<!--StartFragment-->

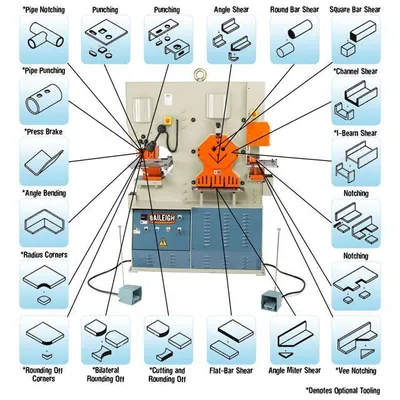

<p>Looking to increase productivity in your shop? This hydraulic ironworker enables 2 operators to work independently at any of the machine’s 5 stations. Plus, the machine’s pure vertical movement minimizes distortion and delivers clean cuts every time.</p>

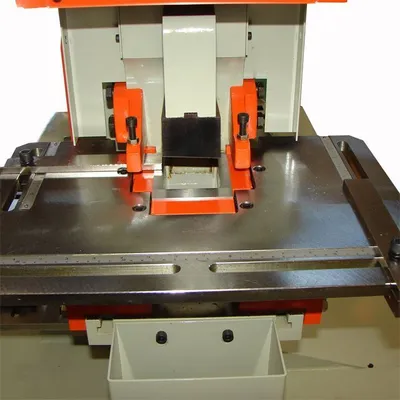

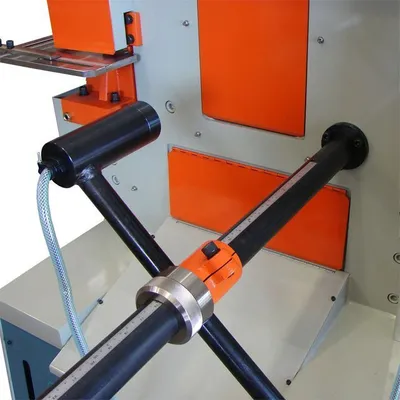

<ul><li>Runs on 220-volt 3-phase power.</li><li>95 tons of punching pressure and a whopping 123 tons of shearing and notching force.</li><li>5 integrated workstations each execute a different function: punching, notching, flat bar shearing, angle shearing, and bar shearing.</li><li>Dual-operator design enables 2 people to work at opposite ends of the machine simultaneously without loss of power at either station.</li><li>Hydraulic cylinders use entirely vertical movement to perform all functions.</li><li>Electric backgauge and adjustable material stops save you effort and deliver precise results for production runs.</li><li>Large worktables separate into 2 pieces, allowing you to get angle iron and oddly-shaped materials to the punch without difficulty.</li><li>Includes 7 sets of punches and dies to accommodate a variety of applications.</li><li>Accepts universal tooling. Jog dial allows for simple and secure tool alignment.</li><li>Foot pedal provides convenient stop and start control.</li><li>Adjustable stroke control of both the upward and downward strokes limits movement and reduces costs.</li><li>Extra-deep 16” throat depth at the punch station handles large pieces of material and increases capacity.</li><li>Hydraulic hold-downs at the shear station ensure safe operation and even cuts.</li><li>Waste buckets keep your shop neat and reduce time spent on clean-up.</li><li>Heavy structural steel plate framework ensures rigidity and eliminates flexing.</li><li>Baileigh covers this ironworker with a 1-year parts warranty and lifetime technical support by phone.</li><li><!--StartFragment-->Country of Manufacture<!--EndFragment-->: Taiwan</li></ul>

<p>Why choose the SW-95 over similar machines?</p>

<ul><li>You won’t find another ironworker that can muster such heavy force across 5 function stations.</li><li>Vertical hydraulic movement needs less clearance and decreases material waste. By contrast, many competing brand ironworkers depend on less efficient pivot mechanisms.</li><li>The SW-95 will let you finish tasks twice as fast by enabling 2 people to use it at the same time.</li><li>Punch tooling lasts longer on the SW-95 because stress is spread out over the entire circumference of the punch instead of just one edge.</li><li>Baileigh’s patented swing-away stripper allows for the quickest tooling changes in the industry.</li><li>Comes standard with a number of extras, like waste buckets and oversized work tables, features that other manufacturers consider upgrades.</li></ul>

<!--EndFragment-->