<!--StartFragment-->

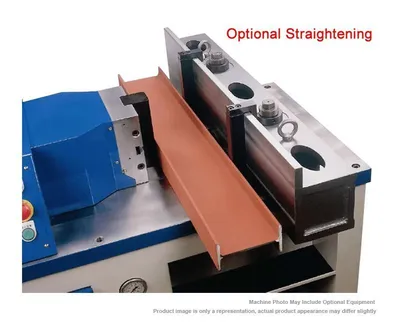

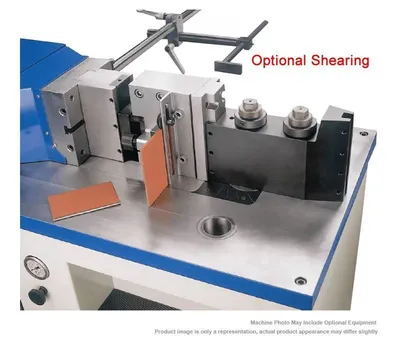

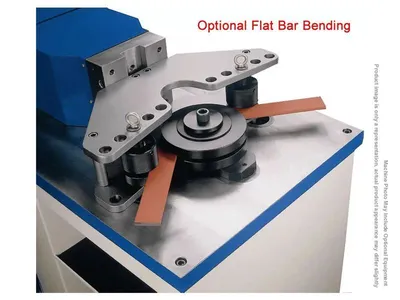

<ul><li>Making smaller parts? This Baileigh horizontal press brake can save time and money, since material lies on the table and stays square. The HPB-78NC industrial hydraulic press brake can shear, bend, punch, and straighten.</li><li>Also available in a 45-ton horizontal press brake machine.</li><li>Recommended for:<ul><li>Full industrial production, including shipbuilding yards, boiler manufacturers, nuclear applications.</li><li>Making parts that are thick, but not wide (die size is limited).</li></ul></li><li>Electronic encoders make this hydraulic press brake accurate to +/- .002”</li><li>Control the bending stroke with 2 buttons or with the foot pedal, so your hands are free to guide the material. Numerical control (NC) programmer can store up to 50 programs with 10 bends per program</li><li>You can adjust the pressure of the hydraulics for your material. You can also run the machine in a manual mode for one-off projects as well as set-up</li><li>Robust manual back gauge bolts to the machine and helps with repeatability and product counter makes production runs more efficient</li><li>Machined table, 37.4” high, keeps your material perfectly level. No need to hold one side and hope it’s lined up!</li><li>Quick-release tooling system makes changes fast and simple. Just turn the handle and the post will lift. The V die slides in and out</li><li>Includes a set of single-V tooling (V-opening die and V post). Also accepts attachments for punching, straightening, shearing, and even pipe bending</li><li>Many additional tooling sets are available. We can find the right one for your project or create a custom set, if necessary</li><li>4,580-pound steel frame, made from 4 powerful pieces of inch-thick flat bar, will keep results accurate for many years and won’t flinch under pressure</li><li>Industrial-grade hydraulic system is located on top of the machine to reduce flex and shelving in the front can hold tooling and items you might need on a daily basis</li></ul>

<!--EndFragment-->