<table width="520" cellspacing="0" cellpadding="0" border="1">

<tbody style="text-align: center;">

<tr>

<td class="TableText" width="257" bgcolor="#cccccc">

<div align="center">Forming Width

</div>

</td>

<td class="TableText" width="257">

<div align="center">60"

</div>

</td>

</tr>

<tr>

<td class="TableText" bgcolor="#cccccc">

<div align="center">Roll Speed

</div>

</td>

<td class="TableText">

<div align="center">5.85 rpm.

</div>

</td>

</tr>

<tr>

<td class="TableText" bgcolor="#cccccc">

<div align="center">Upper Roll Dia.

</div>

</td>

<td class="TableText">

<div align="center">4.75"

</div>

</td>

</tr>

<tr>

<td class="TableText" bgcolor="#cccccc">

<div align="center">Roll Adjustment Back

</div>

</td>

<td class="TableText">

<div align="center">Hydraulic

</div>

</td>

</tr>

<tr>

<td class="TableText" bgcolor="#cccccc">

<div align="center">Minimum Forming Dia

</div>

</td>

<td class="TableText">

<div align="center">7.125"

</div>

</td>

</tr>

<tr>

<td class="TableText" bgcolor="#cccccc">

<div align="center">Motor

</div>

</td>

<td class="TableText">

<div align="center">2 HP

</div>

</td>

</tr>

<tr>

<td class="TableText" bgcolor="#cccccc">

<div align="center">Capacity (Mild Steel)

</div>

</td>

<td class="TableText">

<div align="center">10 ga. (.135")

</div>

</td>

</tr>

<tr>

<td class="TableText" bgcolor="#cccccc">

<div align="center">Power

</div>

</td>

<td class="TableText">

<div align="center">220V / 3-phase

</div>

</td>

</tr>

<tr>

<td class="TableText" bgcolor="#cccccc">

<div align="center">Shipping Dimensions (L / W / H)

</div>

</td>

<td class="TableText">

<div align="center">93" x 30" x 50"

</div>

</td>

</tr>

<tr>

<td class="TableText" bgcolor="#cccccc">

<div align="center">Shipping Weight

</div>

</td>

<td class="TableText">

<div align="center">4,290 lbs

</div>

</td>

</tr>

</tbody>

</table>

<p>Specifications are subject to change without notice.

</p>

<p>NOTE: Data is provided by the manufacturer.

</p>

<p><strong>WARRANTY: 1 YEAR</strong> – Parts

</p>

<ul>

<li>

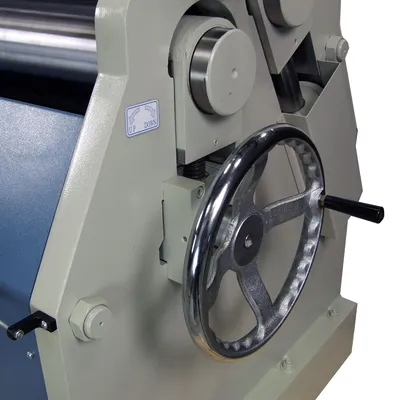

The PR-510 is a great value <strong>hydraulic</strong> plate roll that would be at home in any shop. Its <strong>rigid steel frame</strong> prevents deflection, so you can accurately bend at maximum capacity for years.

</li>

<li><strong>5’</strong> working width.</li>

<li><strong>10 gauge</strong> mild steel capacity across its full width.</li>

<li><strong>2 hp</strong> motor runs on <strong>220-volt 3-phase</strong> power.</li>

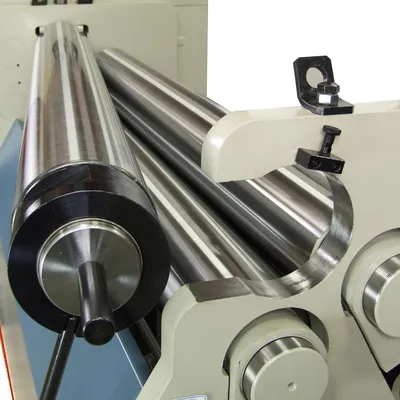

<li>Single pinch roll former has <strong>3 driven rolls</strong> to increase the efficiency of the machine.</li>

<li>4-¾“ OD rolls are <strong>hardened, then polished</strong> to ensure no marring to the material.</li>

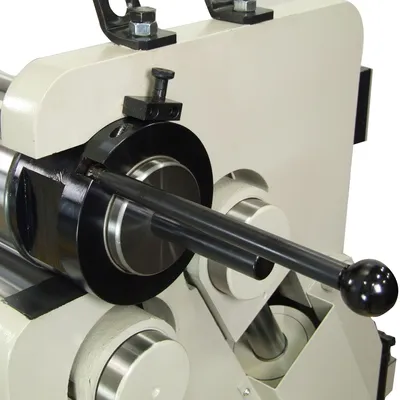

<li><strong>Hydraulically controlled back roll</strong> can move up and down and tilt left and right for coning.</li>

<li><strong>Digital readout</strong> displays the back roll position for repeatable bends.</li>

<li>Fully welded <strong>plate steel frame</strong> eliminates any deflection of the rolls even at maximum thickness capacity.</li>

<li>Covered by a <strong>1-year parts warranty</strong>.</li>

<li>Includes <strong>lifetime technical support by phone</strong> from a team of reps with hands-on experience.</li>

<li><em>Optional coning attachment available.</em> </li>

</ul>