<table width="520" cellspacing="0" cellpadding="0" border="1">

<tbody style="text-align: center;">

<tr>

<td class="TableText" width="319" bgcolor="#cccccc">

<div align="center">Shear Length

</div>

</td>

<td class="TableText" width="319">

<div align="center">52"

</div>

</td>

</tr>

<tr>

<td class="TableText" width="319" bgcolor="#cccccc">

<div align="center">Motor

</div>

</td>

<td class="TableText" width="319">

<div align="center">15 HP

</div>

</td>

</tr>

<tr>

<td class="TableText" width="319" bgcolor="#cccccc">

<div align="center">Strokes Per Minute

</div>

</td>

<td class="TableText" width="319">

<div align="center">30 - 42

</div>

</td>

</tr>

<tr>

<td class="TableText" width="319" bgcolor="#cccccc">

<div align="center">Front Gauge Length

</div>

</td>

<td class="TableText" width="319">

<div align="center">39.37"

</div>

</td>

</tr>

<tr>

<td class="TableText" width="319" bgcolor="#cccccc">

<div align="center">Blade Angle

</div>

</td>

<td class="TableText" width="319">

<div align="center">1/2°

</div>

</td>

</tr>

<tr>

<td class="TableText" bgcolor="#cccccc">

<div align="center">Blade Gap Adjustment

</div>

</td>

<td class="TableText">

<div align="center">Manual, Lever Acuated

</div>

</td>

</tr>

<tr>

<td class="TableText" width="319" bgcolor="#cccccc">

<div align="center">Power

</div>

</td>

<td class="TableText" width="319">

<div align="center">220V / 3-phase

</div>

</td>

</tr>

<tr>

<td class="TableText" width="319" bgcolor="#cccccc">

<div align="center">Minimum Material Thickness

</div>

</td>

<td class="TableText" width="319">

<div align="center">24 ga

</div>

</td>

</tr>

<tr>

<td class="TableText" width="319" bgcolor="#cccccc">

<div align="center">Shipping Dimensions

</div>

</td>

<td class="TableText" width="319">

<div align="center">91" x 54" x 65"

</div>

</td>

</tr>

<tr>

<td class="TableText" width="319" bgcolor="#cccccc">

<div align="center">Shipping Weight

</div>

</td>

<td class="TableText" width="319">

<div align="center">5,720 lbs.

</div>

</td>

</tr>

</tbody>

</table>

<p>Specifications are subject to change without notice.

</p>

<p>NOTE: Data is provided by the manufacturer.

</p>

<p><strong>WARRANTY: 1 YEAR</strong> – Parts

</p>

<ul>

<li> Built for years of heavy cutting, this <strong>numerically controlled</strong> shear makes industrial production runs more efficient. <strong>Blade gap and rake angle adjustment</strong> ensure high cut quality. <br>

</li>

<li>These hydraulic sheet metal shears cut up to <strong>52”-wide</strong> sheet metal.</li>

<li>Maximum capacity of <strong>¼” mild steel</strong>.</li>

<li>15 hp motor runs on <strong>220-volt 3-phase</strong> power.</li>

<li>Upper blade carriage that rides in a 3-axis bearing housing.</li>

<li>Heavy-duty precision ground and <strong>hardened rail system</strong> gives you unbeatable accuracy and long blade life.</li>

<li><strong>Front and rear supports</strong> and side guides help you keep material square to the blade.</li>

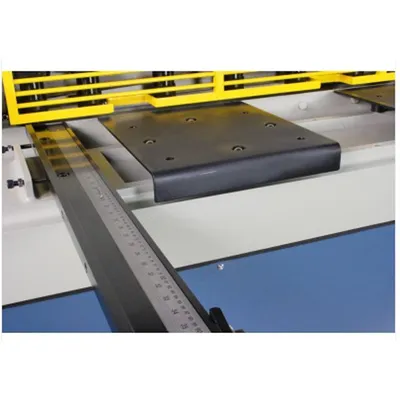

<li><strong>Roller infeed table</strong> makes it easy to maneuver heavy plate steel for the next cut.</li>

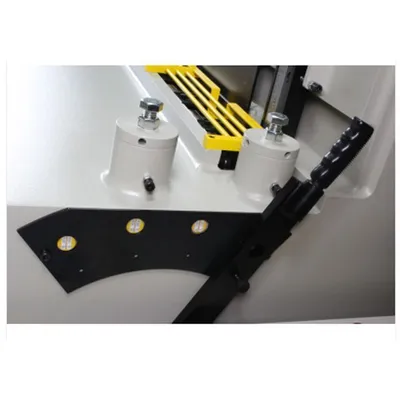

<li><strong>8 hydraulic hold-downs</strong> provide 3.2 tons of pressure each, preventing sheet metal from lifting.</li>

<li><strong>Programmable quick-change backgauge</strong> rides on a screwball rail system with a positioning encoder.</li>

<li>Switch between <strong>3 modes</strong> as needed:

<ul>

<li>Jog mode: Inching the blade down to the material.</li>

<li>Single cycle mode: One cut for one pedal push.</li>

<li>Automatic cycling mode: Continuously cutting for production runs.</li>

</ul>

</li>

<li><strong>Piece counter</strong> makes it simpler to do production runs.</li>

<li>Remote operator control pendant houses an E-Stop button and foot pedal controls.</li>

<li>Simple handle lets you <strong>adjust the blade gap in seconds</strong> to avoid crimping or folding, particularly with thinner material.</li>

<li><strong>Adjustable rake angle</strong> can change for your material thickness, giving you cleaner cuts and reducing strain on the hydraulics.</li>

<li>It’s simple to set the rake angle: just hit a button, move the lever, and a light goes on when you reach the correct angle.</li>

<li><strong>High carbon chromium blades</strong> that have several edges (2 on top, 4 on bottom), so you can flip them several times before you need to resharpening.</li>

<li><strong>Shadow light</strong> stretches the entire length of the web width for proper placement of the beginning of the cut, for those one-off shearing requirements.</li>

<li><strong>Fully welded plate steel framework</strong> maintains stability, reduces flex, and minimizes burr.</li>

<li>Covered by a <strong>1-year parts warranty</strong>.</li>

<li>We stock blades and replacement parts at our Wisconsin warehouse; we can ship them out quickly.</li>

</ul>