<!--StartFragment-->

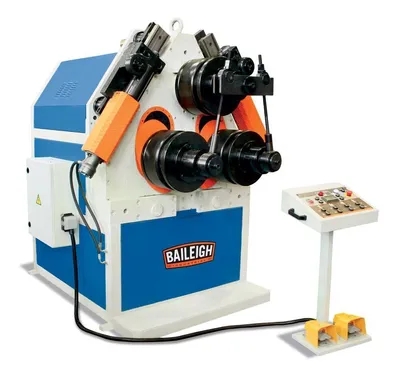

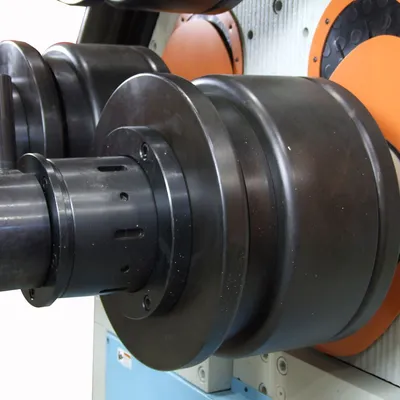

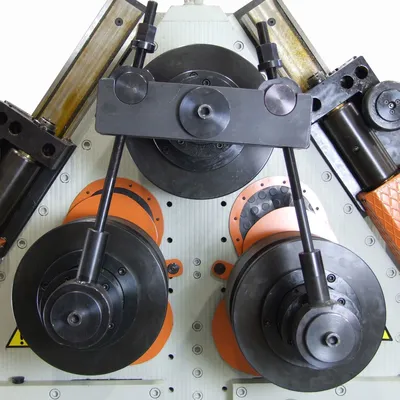

<ul><li>The programmable double-pinch design of this Tube Roller lets you make repeatable bends and complex parts with ease.<br></li><li>Recommended for: Structural applications, playgrounds, shipyard building, or any high-production, low-waste project.</li><li>3 driven rolls run on 220-volt 3-phase power</li><li>Rolls up to 6.25” round tube and 4.75” x 4.75” x 0.5” angle iron</li><li>Hydraulic cylinders connected to 2 bottom rolls accomplish pre- and post-bending to cut down on material waste</li><li>Digital readout displays positions of bottom rolls</li><li>You can program stops for each shaft for precise results</li><li>Movable operator podium includes control buttons and attached foot pedals to specify roll direction</li><li>Operate this ring roller in vertical position or lay it on its back, in horizontal position, for large radius jobs and long material sections</li><li>The machine’s heavy steel plate frame, bolted and welded together, minimizes flex, and ensures accuracy over years of profitable production<br></li><li>Why choose the R-H150 hydraulic roll bender over similar machines?<ul><li>Double-pinch design eliminates wasted length of straight material at the ends of parts, a problem associated with most roll benders—but not this one!</li><li>The R-H150 comes standard with lateral guide rolls for smooth angle correction, a feature that our competitors charge for as an upgrade.</li><li>Digital readout helps you monitor precision, so you can take on production runs without hassle.</li><li>We manufacture and stock optional tooling sets to fit many applications. Ask us which one would work best for your jobs!</li><li>You can count on Baileigh’s team of experienced customer service reps for machine troubleshooting and project hacks—just a phone call away.</li></ul></li><li>We also offer a Vertical Metal Cutting Band Saw.</li><li>Baileigh backs this Tubing Roller with a 1-year parts warranty and lifetime technical support by phone.</li></ul>

<!--EndFragment-->