<table width="520" cellspacing="0" cellpadding="0" border="1">

<tbody style="text-align: center;">

<tr>

<td class="TableText" width="257" bgcolor="#cccccc">

<div align="center">Country of Manufacture

</div>

</td>

<td class="TableText" width="257">

<div align="center">United States

</div>

</td>

</tr>

<tr>

<td class="TableText" width="257" bgcolor="#cccccc">

<div align="center">Notching Capacity (OD)

</div>

</td>

<td class="TableText" width="257">

<div align="center">.75" - 3"

</div>

</td>

</tr>

<tr>

<td class="TableText" width="257" bgcolor="#cccccc">

<div align="center">Angle Adjustment

</div>

</td>

<td class="TableText" width="257">

<div align="center">0 – 60°

</div>

</td>

</tr>

<tr>

<td class="TableText" bgcolor="#cccccc">

<div align="center">Belt Size

</div>

</td>

<td class="TableText">

<div align="center">6" x 79"

</div>

</td>

</tr>

<tr>

<td class="TableText" width="257" bgcolor="#cccccc">

<div align="center">Belt Speed

</div>

</td>

<td class="TableText" width="257">

<div align="center">5400 (fpm)

</div>

</td>

</tr>

<tr>

<td class="TableText" bgcolor="#cccccc">

<div align="center">Motor

</div>

</td>

<td class="TableText">

<div align="center">5 hp

</div>

</td>

</tr>

<tr>

<td class="TableText" bgcolor="#cccccc">

<div align="center">Power

</div>

</td>

<td class="TableText">

<div align="center">220V / 1-phase

</div>

</td>

</tr>

<tr>

<td class="TableText" bgcolor="#cccccc">

<div align="center">Shipping Dimensions (L x W x H)

</div>

</td>

<td class="TableText">

<div align="center">78" x 48" x 52"

</div>

</td>

</tr>

<tr>

<td class="TableText" width="257" bgcolor="#cccccc">

<div align="center">Shipping Weight

</div>

</td>

<td class="TableText" width="257">

<div align="center">475 lbs.

</div>

</td>

</tr>

</tbody>

</table>

<p>Specifications are subject to change without notice.

</p>

<p>NOTE: Data is provided by the manufacturer.

</p>

<p><strong>WARRANTY: 1 YEAR</strong> – Parts

</p>

<ul>

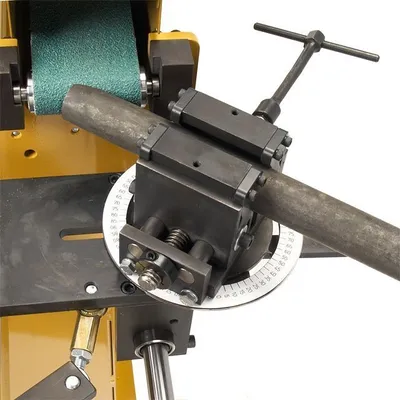

<li><strong>Made in the USA</strong>, the TN-600 abrasive notcher combines a powerful <strong>5 hp motor</strong> with state-of-the-art features like a <strong>patented self-centering vise</strong> and a polished slideway.</li>

<li>Requires only <strong>220 volts of single-phase power</strong>.</li>

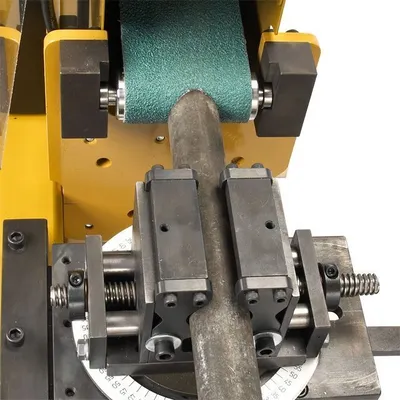

<li>Notches <strong>up to 3” OD tubing at 60°</strong> with optional mandrels.</li>

<li>Wide <strong>6” x 79” belt</strong> spins at <strong>5400 feet per minute</strong>.</li>

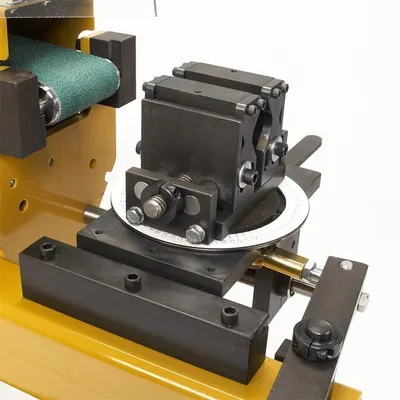

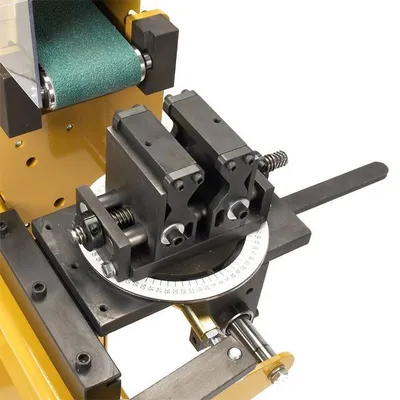

<li><strong>Adjustable stop</strong> for repeatable parts during production runs.</li>

<li><strong>Large degree dial</strong> to reference the degree of the notch.</li>

<li>Self-centering vise lets you <strong>switch between materials quickly</strong> and start the tube or pipe the proper position on the belt.</li>

<li>V-jaws of the vise <strong>tightly grip both light- and heavy-gauge tube</strong>.</li>

<li><strong>Quick-release vice</strong> allows for efficient movement of material to ensure accuracy of the notch.</li>

<li><strong>Smooth rail system</strong>, controlled by an industrial helm joint and a polished slideway, feed the material into the belt.</li>

<li>You can <strong>adjust belt tension</strong> with the convenient wheel.</li>

<li>Purchase <strong>many sizes of mandrels, available separately</strong>. Baileigh typically keeps them in stock for fast shipments.</li>

<li>Covered by a <strong>1-year parts warranty</strong> and <strong>lifetime technical support by phone</strong>.</li>

<li><strong>Why choose the TN-600 Abrasive Tube Notcher over similar machines?</strong> </li>

<li>The TN-600’s cutting-edge vise guarantees that <strong>your piece of tube or pipe will always line up correctly</strong>. No more worrying about damaging the machine or losing time on set-ups.</li>

<li>Simple mandrel tooling system and quick-release vice <strong>save you valuable seconds and minutes on any project time</strong>.</li>

<li>We’re proud to say this tube and pipe notcher for sale is <strong>made in America</strong>, like many of Baileigh Industrial’s other signature machines.</li>

<li>Baileigh offers <strong>unlimited remote support</strong> from a team of reps who all have hands-on experience using our machines.</li>

</ul>