<!--StartFragment-->

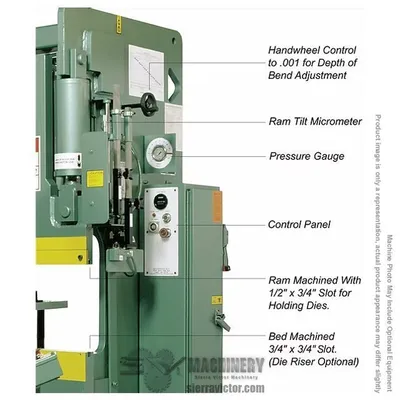

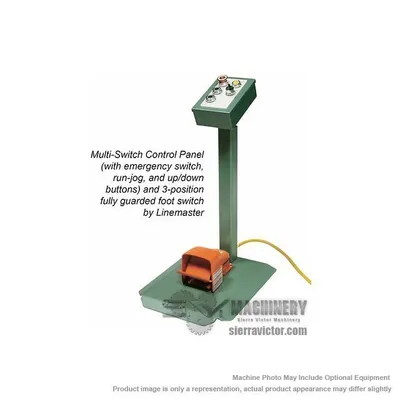

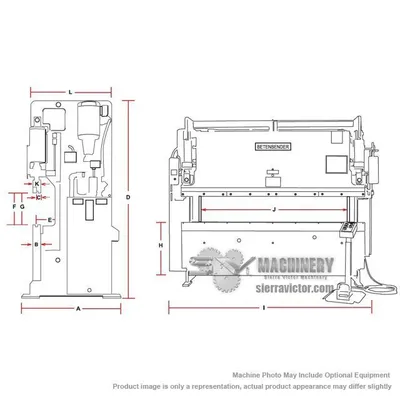

<ul><li>** <strong>FREE SHIPPING TO COMMERCIAL ADDRESS THAT CAN OFFLOAD**</strong></li><li><strong>MADE IN USA</strong></li><li><strong>Frame</strong>: The frame is of open throat design with mounting holes in feet. Drilled and tapped holes in feet allow for leveling of the machine.</li><li><strong>Bed</strong>: The machined flat surface is slotted full length to accommodate standard die holders, filter blocks, misc.</li><li><strong>Front & Back of Bed</strong>: The bed is machined down 4” on the front and 12” on the back to allow a flat surface for mounting various brackets, supports and gauges.</li><li><strong>Ram</strong>: The ram is constructed of solid steel slotted to accept standard dies. The clamping bar is sectional for positive clamping. The upper is machined up to 4” to allow a flat surface for mounting brackets and gauges.</li><li><strong>Ram Tilt Adjustment</strong>: The micrometer spindle is located on the right side end frame of machine, which allows for adjustment of the desired angle required up to ±0.500 inch. The micrometer allows the operator to return to a given setting, parallel to desired angle. By using the micrometer reading, the machine can return to previous position.</li><li><strong>Ram Level</strong>: The ram level is accomplished by two hydraulic systems, one for each cylinder, which keeps them parallel. The ram self-levels at the bottom of each stroke even if hydraulic system is out of adjustment.</li><li><strong>Hydraulic Cylinders</strong>: Direct acting hydraulic cylinders are one piece, double acting with self-aligning, hardened ball sockets.</li><li><strong>Accuracy</strong>: Parallelism is maintained at ±0.002 inch in low speed.</li><li><strong>Operating Controls</strong>:<ul><li>1. Pull to start. Push off. Light is on when in the “ON” position.</li><li>2. Run/Jog switch. Run position for normal operation. Jog position for loading of tooling, maintenance and set-up.<br>Up/Down buttons are used when in jog.</li><li>3. 3 Position Foot Petal<br>a. Ram up<br>b. Ram hold<br>c. Foot petal down. Ram down allows or jogging of ram down and holding. Emergency stop and emergency up buttons are located on a small pedestal that comes from the foot petal.</li><li>4. Cycle time delay at bottom of stroke</li></ul></li><li>*When using top & bottom tools on a press brake, a forming system is created which requires analysis to determine the appropriate safeguarding for operator safety and protection.</li><li>*It is the user’s responsibility to ensure that the point of operation is effective and all applicable safety requirements are met.</li><li><strong>Stroke Control (Optional)</strong>: Control of strokes in accomplished by rotation of hand wheels, which read in thousandths of an inch and set the closed height. When the machine is 2 or 3 speed, the knob for setting the speed change point is located on right side for simple adjustments.</li><li><strong>Tonnage Control (Optional)</strong>: Our machines are equipped with optional adjustable<br>tonnage control to go from lower tonnage to rated tonnage of machine, as well as overload protection.</li><li>Backgauge: A slide and clamp, 3 axis backgauge 24” is standard.<ul><li>1. Front operated manual backgauge, hand wheel with mechanical readout (0.01)</li><li>2. Front operated power backgauge with LED readout (0.001)<br>CNC backgauging and front gauging is optional.</li></ul></li><li><strong>Front Support Arms (Optional):</strong> 24” support arms are “slide” type. Optional disappearing stops help to hold the material from sliding backward.</li><li><strong>Electrical System</strong>: The electrical systems meet NFPA 79 standards. All machines have<br>disconnect switches, magnetic starters, 110/120v controls, 208-230/460v 3 phase, others optional.</li><li><strong>Motors</strong>: Our American made motors are rated for continuous duty, open drip.</li><li><strong>Lubrication</strong>: Grease zerks are standard. One shot lube or automatic lubrication is optional.</li><li><strong>Safety Features</strong>: Betenbender Hydraulic Press Brakes and Shears are built to meet ANSI B11.3 standards. Safety features of the Betenbender Press Brake include:<br><ul><li>Emergency stop on pedestal</li><li>Emergency up on pedestal</li><li>Warning signs, safety markings and covers</li><li>Electronics meet NFPA 79 standards</li><li>110/120v control</li></ul></li><li>Specifications are subject to change withoutnotice.</li><li>Compliance with OSHA requirements is the legal responsibility of the user and is subject to local inspectors’ interpretation of existing standards.</li><li>Betenbender Shears are built to meet ANSI B11.3 standards</li></ul>

<p><strong>STANDARD EQUIPMENT:</strong></p>

<ul><li>Clamp Type Backgauge-Manual Adjustment X, Y, and Z</li><li>Two Speed Ram</li><li>Bottom Time Delay</li><li>Three Position Foot Pedal</li><li>Depth Stop w/Digital Readout</li><li>Three Speed (95T and Larger)</li><li>American Made Motors</li><li>Hour Meter</li><li>Nema Electrics</li><li>All Hydraulic Fluids Included</li><li>Disconnect Switch</li><li>All Steel Construction</li><li><strong>NOTE: DIE RISERS NOT FURNISHED</strong></li></ul>

<!--EndFragment-->